-

Carbon fiber used in transportation

-

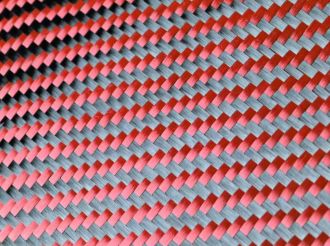

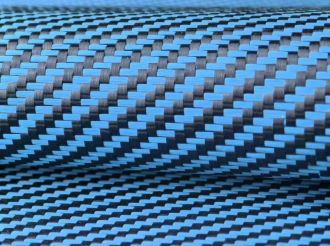

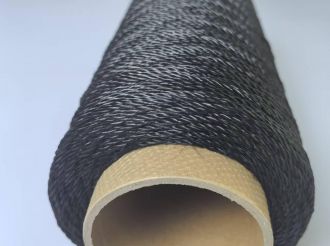

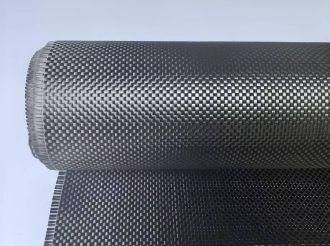

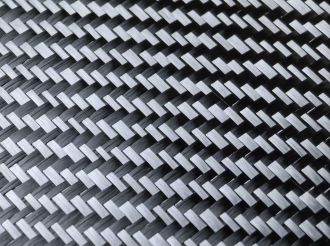

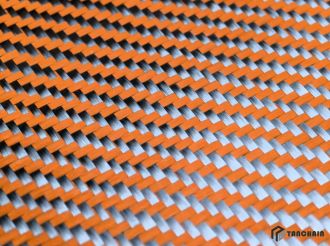

Carbon fiber is called black gold, Carbon fiber can enhance the strength and reduce the weight in transportation

●Carbon fiber auto parts

The use of carbon fiber composite parts is mainly based on the following considerations:

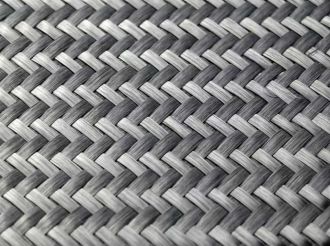

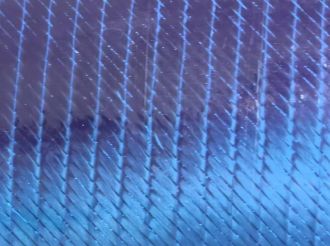

one is for the lightweight body.Carbon fiber density is low, compared to carbon steel weight reduction of 50%, compared to magnesium/aluminum alloy structure weight reduction of 30%;

Second, high integration.Free modeling, strong designability, can achieve streamlined and curved surface, can reduce the types of parts and tooling investment;

Third, improve production efficiency.Replace stamping and welding with die pressing and bonding process, save the investment of production line, die and fixture;

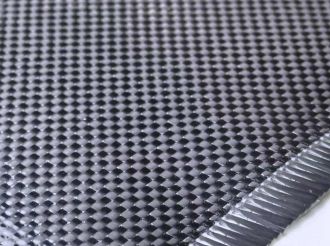

Fourth, improve the safety performance of cars.Carbon fiber has high fatigue strength (up to 70%~80% of the design load), the center of gravity drops after the weight reduction, and the operation stability is higher.

Moreover, the collision energy absorption capacity of carbon fiber is 6-7 times that of steel and 3-4 times that of aluminum.Five is to improve the comfort of cars.Higher vibration damping, the overall noise reduction of the car has an obvious effect, make passenger comfort better.

From the original car to high-end commercial vehicles, and more popular in recent years, new energy vehicles, the application of carbon fiber parts footsteps never stop, such as wuxi wisdom on new materials, in accordance with requirements of the new energy auto manufacturing carbon fiber power battery box body is carbon fiber composites in the typical application cases, on the new energy vehicles in the aspects such as weight loss, impact resistant effectively improved the performance of the new energy vehicles.

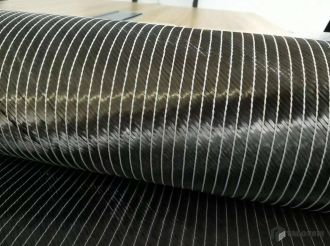

●Carbon fiber in high-speed train

The lightweight solution of high-speed rail has always focused on two issues: one is that lightweight materials must have sufficient safety; the other is to try to be as light as possible under the premise of ensuring safety, so as to achieve greater capacity and higher transport efficiency.

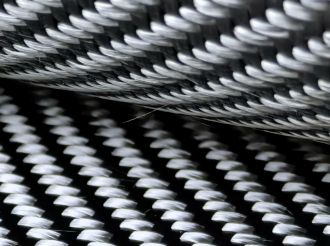

From bullet trains with speeds of 400 km/h or above, double-decker trains to high-speed maglev trains with speeds of 600 km/h, high-speed railway and other rail vehicles have been developing towards high-speed, efficient, green, intelligent and other goals. Among them, the body materials that are both light and strong play a crucial role.The selected materials of the car body, in the strength, stiffness, fatigue resistance, corrosion resistance and fire performance performance, are constantly optimized, carbon fiber composite material has the advantages of light weight, impact reduction, lift load, high weather resistance, high reliability, high availability, high life, little maintenance and so on gradually received attention.

Carbon fiber cab driver operation panel, carbon fiber seat parts, carbon fiber bulkhead plates, etc., as the carbon fiber composite material used in high-speed rail track vehicles such as proportion of more and more big, wuxi wisdom on the new material will face technical requirements also more and more high, this also in virtually also driving the domestic carbon fiber composite material applied at a faster pace.

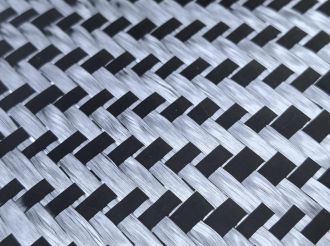

●Carbon fibre aircraft parts

Carbon fiber composite material than strength, high stiffness, good fatigue resistance and corrosion resistance, can design, promote efficiency of structure, not only can improve the aircraft safety, economy, comfort and environmental protection, also can significantly improve the aircraft's fuel efficiency, is currently in the application implements a significant share of civilian aircraft.

At the same time, the use of carbon fiber composites in aircraft also poses new technical challenges.Compared with traditional metal structure, carbon fiber composite structure has anisotropy, and its brittleness makes it significantly different from conventional metal materials in terms of deformation under load, damage mechanism and failure mode.A series of technical problems, such as connection analysis, stability, damage tolerance, fallability, large opening, lightning protection, fire resistance, anti-icing, interlayer analysis, etc., need to be broken through.

Breakthrough airframe and propulsion technologies will be used to reduce aerodynamic drag and save fuel in the overall optimization of aerodynamics, structure and materials.However, when flying at supersonic and ultra-high speed of sound, the high temperature effect of the body structure is obvious, which not only requires the integrated structural design of advanced composite materials like carbon fiber, but also makes them lighter, more resistant to damage and high temperature.

Not only the body parts, aircraft interior parts of the material requirements are also strict.The carbon fiber aviation seat frame plate provided by wuxi zhicang new material technology co., ltd. for a certain type of civil aircraft, in addition to greatly reducing the weight of the seat, to be able to withstand 6-8 years of high frequency pressure, but also to have a certain flame retardant, all of which put forward high requirements for the practical application of carbon fiber composite material.