-

-

1K - Carbon fiber filaments

- Code:TC-CF-1K

- Material:100% Carbon Fiber

- Weight:1k filaments

- Function:High strength, Low weight.

- Color:Black

SEND INQUIRY

Compared with other types of carbon fiber filaments, 1K carbon fiber filaments have the following advantages and disadvantages, cost-effectiveness and main uses:

1. Advantages:

- High fineness: 1K carbon fiber filament is the thinnest in small-tow carbon fiber. The small number of monofilaments allows it to better control the arrangement and distribution of fibers during production and processing, thus having higher fineness and uniformity, and can meet application scenarios with extremely high requirements for product appearance and performance.

- Excellent mechanical properties: It has high strength and modulus, and its strength can withstand large loads. The high modulus makes the material deform less when stressed and has good dimensional stability. Carbon fiber has high axial strength and modulus, low density and high specific performance. At the same weight, the mechanical properties of 1K carbon fiber filament are outstanding.

- Good corrosion resistance: It has good tolerance to chemical substances such as acids, alkalis, and salts, and can maintain stable performance in harsh chemical environments, which can extend the service life of the product.

- Good fatigue resistance: After long-term repeated use and stress, 1K carbon fiber filaments can still maintain good performance and are not prone to fatigue damage.

- Good processing performance: Although carbon fiber is a difficult-to-process material as a whole, 1K carbon fiber filament is relatively thin. In some processes that require high processing precision, such as weaving and winding, it is easier to operate and can produce products with complex shapes and structures.

2. Disadvantages:

- High cost: The production process of 1K carbon fiber filament is complex, with high requirements for equipment and technology, and low production efficiency, resulting in high production costs. Therefore, the price of products using 1K carbon fiber filament is also relatively expensive, limiting its application in some cost-sensitive fields.

- Brittleness: Carbon fiber materials themselves have a certain degree of brittleness, and 1K carbon fiber filament is no exception. When subjected to large impact or bending forces, it is easy to break or damage.

- Limited production capacity: Due to the difficulty of production, the production capacity of 1K carbon fiber filament is relatively low, which is difficult to meet the needs of large-scale production, which also affects its market application scope to a certain extent.

3. Cost-effectiveness:

- From a performance perspective, 1K carbon fiber filament has excellent performance. In fields with extremely high material performance requirements, such as aerospace, high-end sports equipment, precision instruments, etc., its high performance can bring higher value, so the cost-effectiveness is relatively high. For example, when manufacturing key structural components of aircraft or high-end bicycle frames, the high strength and lightweight advantages of 1K carbon fiber filament can meet the design requirements. Although the cost is high, the comprehensive performance and use effect make it have a good cost-effectiveness.

- However, for some fields that are not particularly demanding on performance requirements but have strict cost control, such as ordinary industrial products, building materials, etc., the cost-effectiveness of 1K carbon fiber filament is relatively low. In contrast, large-tow carbon fiber filament or other materials may have more cost advantages.

4. Main uses:

- Aerospace field: used to manufacture aircraft wings, fuselage structural parts, satellite components, etc. In these applications, the lightweight and high-strength characteristics of 1K carbon fiber filament can reduce the weight of aircraft, improve flight performance and fuel efficiency.

- Sporting goods field: can be used to manufacture high-end golf clubs, bicycles, fishing rods, tennis rackets, etc. These sports equipment have high requirements for the weight, strength and stiffness of the materials. 1K carbon fiber filament can meet these requirements while providing a good user experience.

- Medical device field: such as the manufacture of artificial joints, prostheses, surgical instruments, etc. 1K carbon fiber filament has good biocompatibility, high strength and precision, and can meet the special requirements of medical devices for materials.

- Electronic communication field: It can be used to manufacture the shells, antennas and other components of electronic products such as mobile phones and computers, as well as key structural parts in communication equipment. It has good electromagnetic shielding performance and dimensional stability, which can improve the performance and reliability of electronic equipment.

- High-end industrial field: In some high-end industrial fields with extremely high requirements for material performance and precision, such as precision machinery, high-end molds, etc., 1K carbon fiber filament also has certain applications, which can improve the performance and service life of the product.

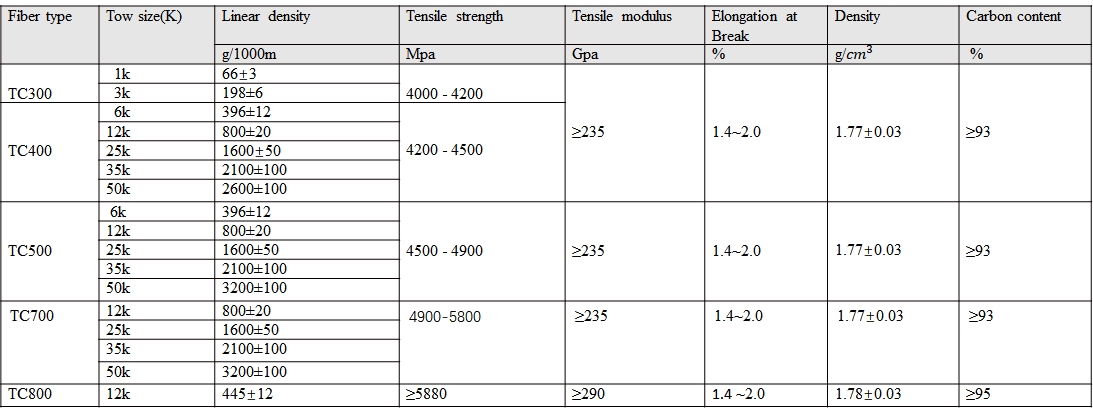

Technical Data

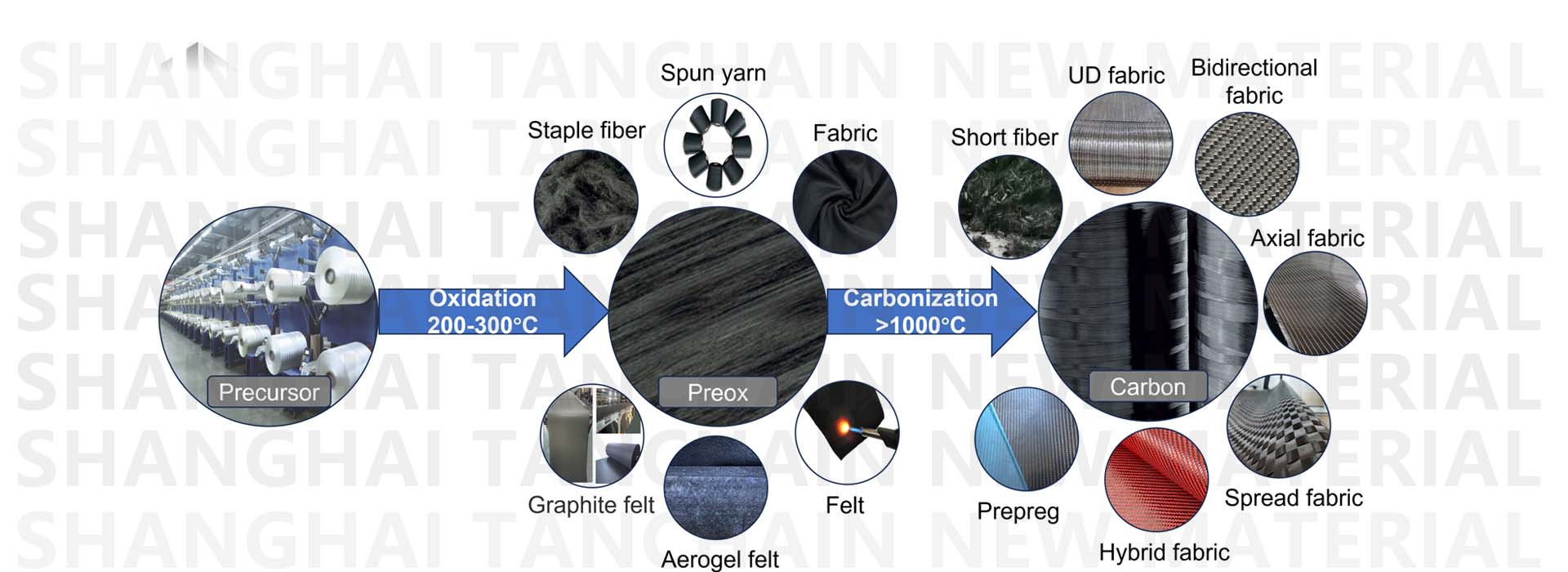

Production Line

Tanchain's Production Flow

SHIPPING