-

-

12K - Carbon fiber filaments

- Code:TC-CF-12K

- Material:100% Carbon Fiber

- Weight:12k filaments

- Function:High strength, Low weight.

- Color:Black

SEND INQUIRY

12k carbon fiber filament has the following characteristics and advantages:

1. Physical properties:

- High strength: Carbon fiber filaments are extremely strong. A bundle of standard 12k carbon fiber filaments can withstand a weight of about 130 kg, which is much stronger than many common metal materials, such as steel and aluminum. This high strength makes 12k carbon fiber filaments have important application value in structures that need to withstand greater stress, and can effectively enhance the bearing capacity of the structure.

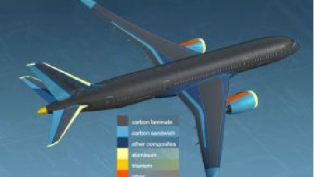

- Low density: The density of carbon fiber is only 1/5 of steel, 2/5 of titanium, and 3/5 of aluminum. 12k carbon fiber filaments also have such low density characteristics. This means that at the same weight, carbon fiber filaments can provide greater strength and rigidity, which is ideal for lightweight application scenarios, such as aerospace, automotive manufacturing and other fields, which can reduce the weight of the overall structure and improve energy efficiency and performance.

- Good dimensional stability: The thermal expansion coefficient of carbon fiber filaments is close to 0, and the size remains basically unchanged between minus 100 degrees Celsius and plus 100 degrees Celsius. This characteristic enables 12k carbon fiber filament to maintain stable size and performance in an environment with large temperature changes, and is not prone to deformation or dimensional deviation due to temperature changes, which is very important for some application scenarios with high dimensional accuracy requirements.

2. Chemical properties:

- Corrosion resistance: Carbon fiber filament has excellent corrosion resistance and can withstand the erosion of various acids, alkalis, salts and organic solvents. In harsh chemical environments, such as chemical industry, marine engineering and other fields, 12k carbon fiber filament can be used stably for a long time, and will not corrode and rust as easily as metal materials, thereby extending the service life of the structure.

- Anti-oxidation: Carbon fiber filament also has good anti-oxidation properties in high temperature and aerobic environments, and can resist the occurrence of oxidation reactions to a certain extent and maintain the stability of its performance. This makes 12k carbon fiber filament advantageous in applications in high temperature or aerobic environments, such as in engine parts, high temperature pipes and other fields.

3. Process characteristics:

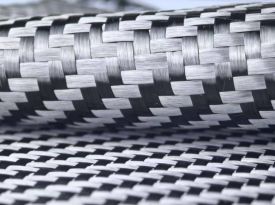

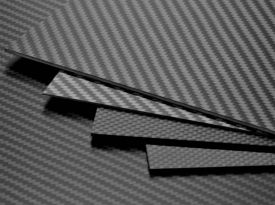

- Good processability: Although carbon fiber filament itself is a high-performance material, it still has good processability. 12k carbon fiber filaments can be processed into products of various shapes and structures through various processes such as weaving, winding, and pultrusion to meet the needs of different application scenarios. For example, it can be woven into carbon fiber cloth for the reinforcement of building structures; it can also be wound around pipes or containers to improve its strength and corrosion resistance.

- Good compatibility with matrix materials such as resins: 12k carbon fiber filaments can be well combined with matrix materials such as resins, metals, and ceramics to form composite materials. In composite materials, carbon fiber filaments, as reinforcements, can significantly improve the strength, stiffness, and wear resistance of the matrix material. At the same time, the matrix material can also protect and support the carbon fiber filaments, thereby improving the overall performance and service life of the composite material.

4. Economic characteristics:

- High cost performance: Among small-tow carbon fibers, the output of 12k carbon fiber filaments is relatively high, and the production process is relatively mature, so its cost is relatively low, and it has a high cost performance. Compared with small-tow carbon fiber with higher k number, 12k carbon fiber filament has achieved a better balance between performance and price. For some application scenarios with high performance requirements but limited budget, 12k carbon fiber filament is a more ideal choice.

- Long service life: Due to its excellent corrosion resistance, oxidation resistance and wear resistance, 12k carbon fiber filament has a long service life. During long-term use, it does not require frequent maintenance and replacement, which reduces the cost of use and maintenance, and has higher economic benefits in the long run.

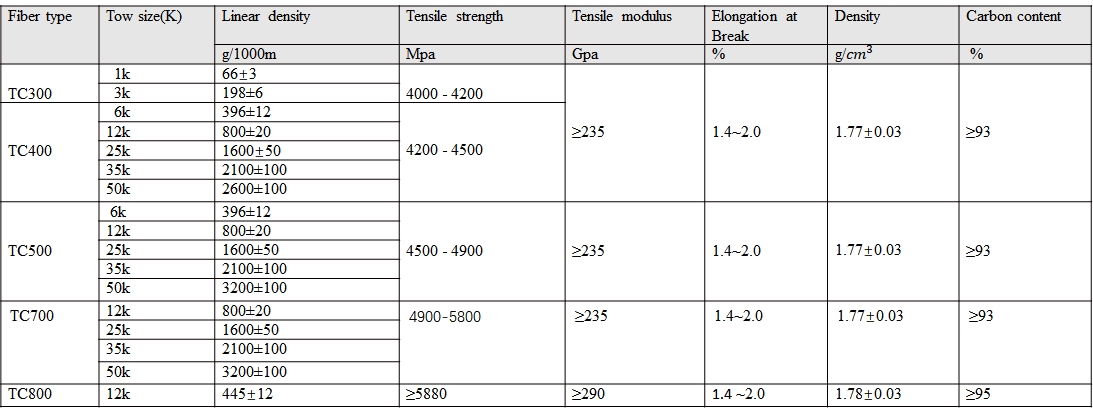

Technical Data

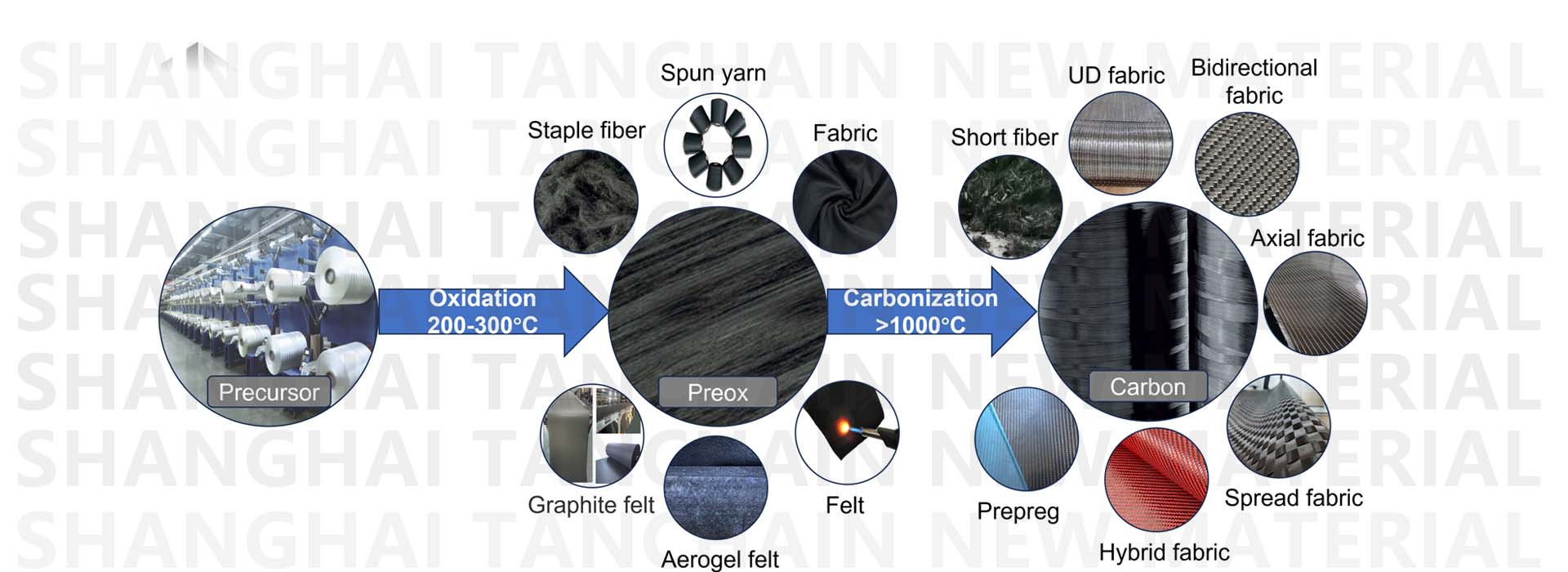

Production Line

Tanchain's Production Flow

SHIPPING