-

-

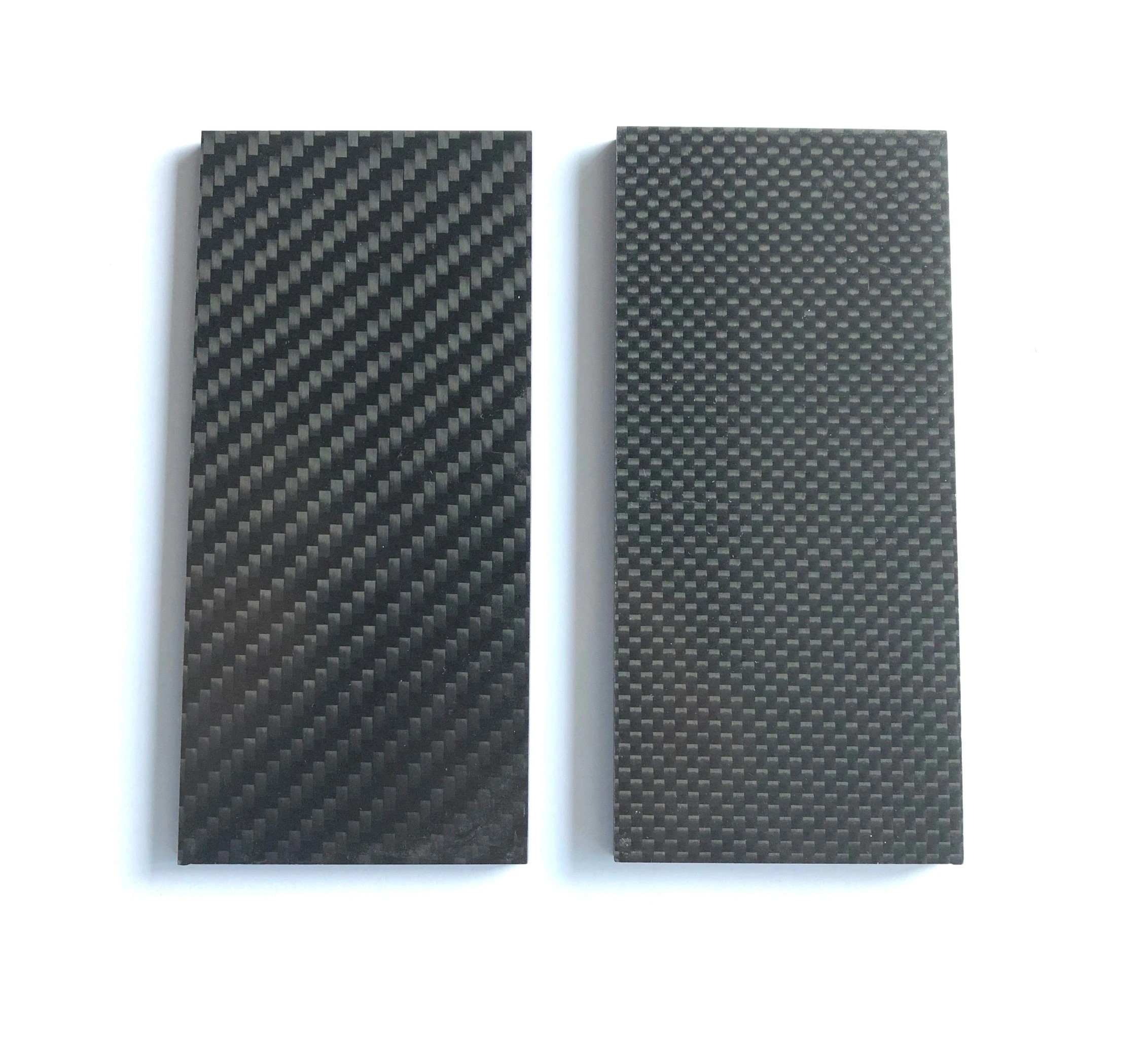

Carbon Fiber Sheets - 3k Carbon sheets 1 1.2 1.5 2 2.5 3 4 5 6 7 8 9 10mm

- Code:TC-CF-CS2

- Material:Carbon fiber

- Weight:1.6-1.7gram/cm3

- Function:High strength, Low weight.

SEND INQUIRY

Parameters of carbon fiber sheets:

| Carbon fiber | T400 |

| Thickness |

1 1.2 1.5 2 2.5 3 4 5 6 7 8 9 10mm |

| Structure | 3K plain/twill |

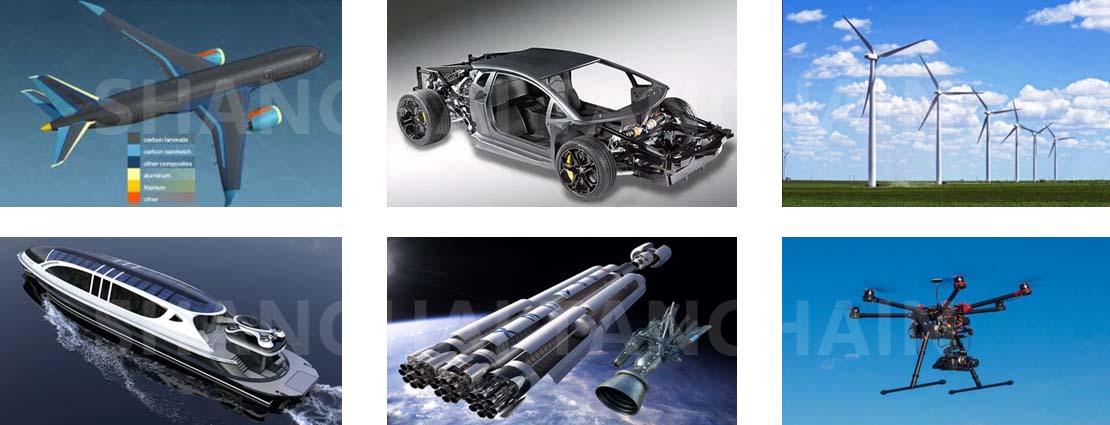

| Application | Aerospace, Automative industry, Medical Devices, Construction Fields, Electronic Equipment |

| Feature | High strength, High modulus |

3K carbon fiber board is a carbon fiber board made of 3K carbon fiber material.

The following is a detailed introduction about it:

1. Material properties:

- High strength: It has extremely high tensile strength, which is several times that of ordinary steel. This makes 3K carbon fiber board have great advantages in structures that need to withstand greater stress. For example, in the aerospace field, it can be used to manufacture structural components of aircraft; in the automotive industry, it can be used to manufacture the body, chassis and other components of high-performance cars, which can reduce weight while ensuring the strength and safety of the vehicle.

- High modulus: The high elastic modulus means that it deforms less when subjected to force and has good rigidity and dimensional stability. This feature is very important for some application scenarios with high dimensional accuracy requirements, such as manufacturing the shell of precision instruments, high-end sports equipment, etc.

- Low density: The density of carbon fiber materials is usually between 1.5-2.0 g/cm3, which is much lower than traditional metal materials such as steel and aluminum alloy. Therefore, 3K carbon fiber board is light in weight, which helps to reduce the weight of the overall structure and has important application value in weight-sensitive fields such as aerospace, drones, etc.

- Corrosion resistance: Carbon fiber has good corrosion resistance and can resist corrosion by chemicals such as acid, alkali, and salt. This allows 3K carbon fiber panels to maintain good performance under harsh environmental conditions and is suitable for applications in the chemical, marine and other fields.

- High temperature resistance: Carbon fiber can still maintain good performance at high temperatures and has high heat resistance. In some applications under high temperature environments, such as engine peripheral components and high-temperature furnace parts, 3K carbon fiber panels can play its advantages.

2. Production process:

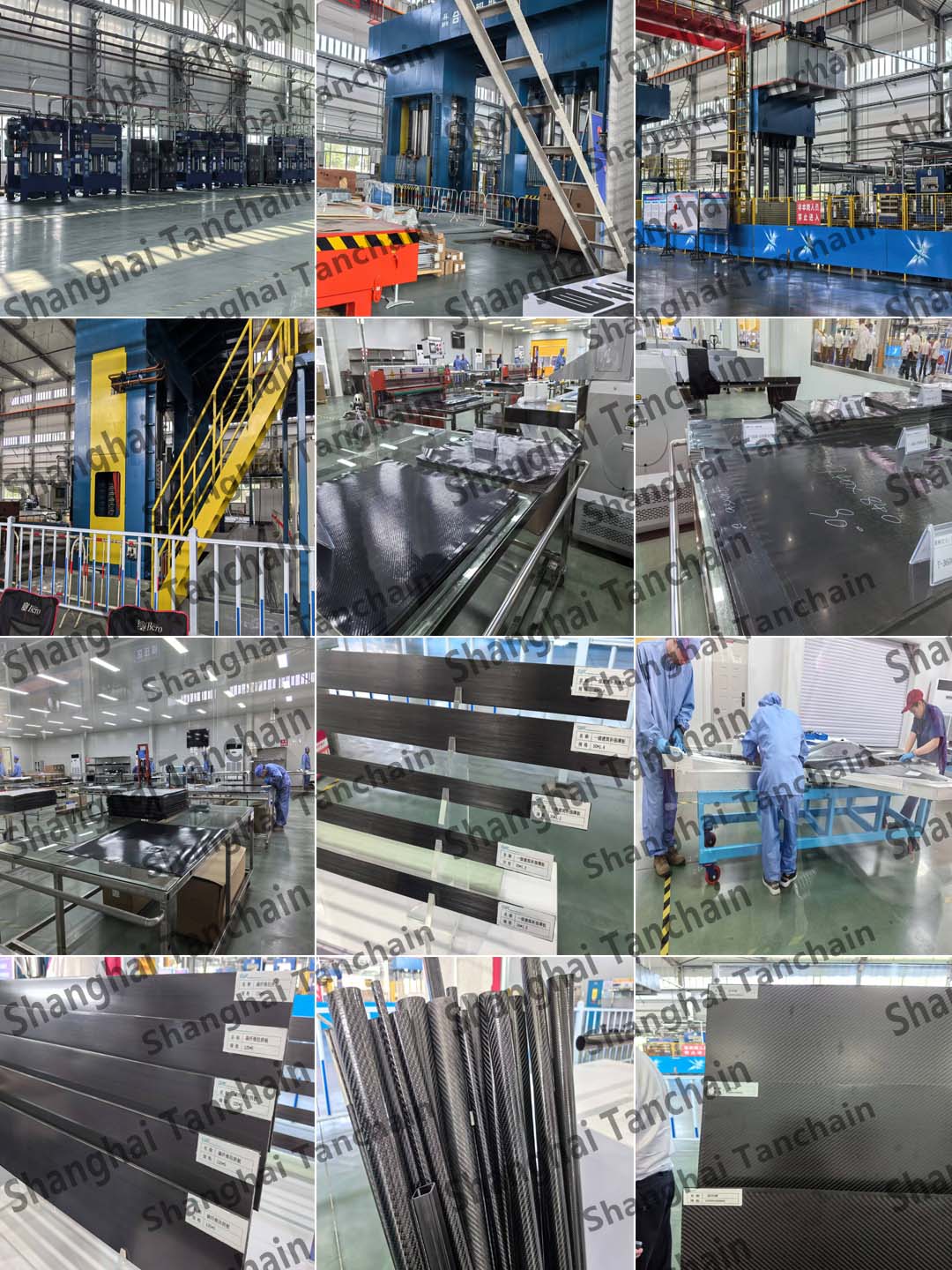

- Prepreg method: First, the carbon fiber tow is impregnated in a resin matrix to make a prepreg. Then the prepreg is laid in the mold according to the design requirements, and the resin is cured by heating, pressurization and other processes to finally obtain a carbon fiber board. This method can accurately control the content and direction of carbon fiber, thereby obtaining a carbon fiber board with excellent performance, but the production process is relatively complicated and the cost is high.

- Molding method: After mixing the carbon fiber tow with the resin, put it into the mold and cure the resin under high temperature and high pressure. The molding method has high production efficiency and is suitable for mass production, but the performance of the product may be affected by the mold accuracy and molding process.

- Winding method: Wind the carbon fiber tow around the core mold, apply resin at the same time, and then heat and cure it. The winding method can produce carbon fiber plates with complex shapes, but it is relatively difficult to control the flatness and dimensional accuracy of the plates.

3. Application areas:

- Aerospace: The wings, fuselage structural parts, satellite structural parts, etc. of aircraft have extremely high requirements for material strength and weight. 3K carbon fiber plates can meet these requirements and help improve the performance of aircraft and reduce fuel consumption.

- Automotive industry: It can be used for the body, hood, chassis parts, etc. of the car, which can reduce the weight of the car, improve fuel efficiency and driving performance, and enhance the safety of the car.

- Sports equipment: Such as bicycles, golf clubs, tennis rackets, skis, etc. The high strength and lightweight characteristics of 3K carbon fiber plates can improve the performance of sports equipment and make athletes more handy when using them.

- Medical devices: Used to manufacture medical bed boards, wheelchairs, prostheses and other medical devices. Its good biocompatibility and mechanical properties can provide patients with better treatment and rehabilitation effects.

- Construction field: It can be used for the reinforcement and repair of building structures, such as bridges, houses, etc., which can improve the bearing capacity and durability of the structure.

- Electronic equipment: Since 3K carbon fiber plates have good electromagnetic shielding properties, they can be used to manufacture electronic equipment housings, radiators and other components to protect electronic equipment from electromagnetic interference.

Product list of carbon fiber sheets/boards

| Model | Pattern |

Width(mm) Can be customized |

Height(mm) Can be customized |

Thickness(mm) Can be customized |

| TC-CF-CS1 | 3k plain/twill | 1000 | 1000 | 1 |

| TC-CF-CS1.2 | 3k plain/twill | 1000 | 1000 | 1.2 |

| TC-CF-CS1.5 | 3k plain/twill | 1000 | 1000 | 1.5 |

| TC-CF-CS2 | 3k plain/twill | 1000 | 1000 | 2 |

| TC-CF-CS2.5 | 3k plain/twill | 1000 | 1000 | 2.5 |

| TC-CF-CS3 | 3k plain/twill | 1000 | 1000 | 3 |

| TC-CF-CS4 | 3k plain/twill |

1000 |

1000 | 4 |

| TC-CF-CS5 | 3k plain/twill | 1000 | 1000 | 5 |

| TC-CF-CS6 | 3k plain/twill | 1000 | 1000 | 6 |

| TC-CF-CS7 | 3k plain/twill | 1000 | 1000 | 7 |

| TC-CF-CS8 | 3k plain/twill | 1000 | 1000 | 8 |

| TC-CF-CS9 | 3k plain/twill | 1000 | 1000 | 9 |

| TC-CF-CS10 | 3k plain/twill | 1000 | 1000 | 10 |

Workshop

Shipping:

APPLICATIONS

Certificate