-

-

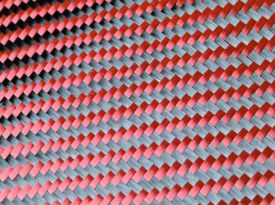

T700 - 200gsm - spread tow carbon fabric - weave locked

- Code:TC-CF-S200P

- Material:12k T700 carbon fabric

- Weight:80g, 100g, 160g, 200g, 240g etc.

- Function:Reinforcement, exterior, surface

- Weave:Plain, Twill

- Width:100cm

SEND INQUIRY

Characteristics of spread carbon fabric:

Carbon fiber spread tow biaxial fabric is woven with carbon fiber spread tow yarn tape. The fabric is lighter and thinner, and the fiber interweaving points are straighter, which is conducive to rapid penetration of resin. When composite products are ultimately limited by design requirements such as thickness, strength, weight, and mechanical properties, the advantages of using carbon fiber spread tow biaxial fabrics are more prominent, and composite products with light weight, high strength, and better mechanical properties can be obtained.

Carbon fiber spread fabric has beautiful appearance and high strength. We use T700 grade carbon fiber filament, widen the yarn to a width of 8mm, 10mm, 16mm or 20mm, and then weave the widened yarn into a spread tow carbon fabric, which can be plain or twill. The carbon spread fabric can be made very thin, which can save the amount of carbon fiber used. At the same time, we use T700 grade carbon fiber to ensure the strength of the carbon fabric.

| Carbon fiber | T700 12k, 24k |

| Weight |

80g, 100g, 160g, 200g, 240g etc. |

| Structure | Twill, Plain |

| Application | Sports, Aerospace, Automobile etc. |

| Feature | beautiful appearance, high strength |

Weave/Pattern locked carbon fabric:

We also provide weave/pattern locked carbon fabric, we use a net on one side of the carbon fiber to fix it and lock the grain of the fabric, making the fabric very stable. In this way, the fibers of the carbon fabric will not shift or deform when we use it, which is beneficial to our use of carbon fabric.

Top side:

Bottom side:

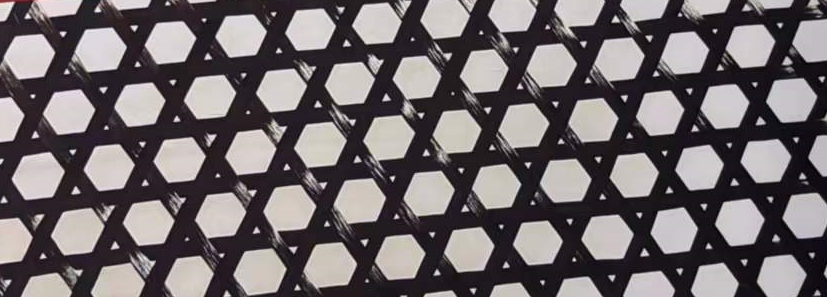

Characteristics of spread tow triaxial fabric:

Traditional biaxial fabrics are formed by two sets of mutually perpendicular yarns interwoven on the same side. Triaxial fabric is a fabric made of three yarns interwoven at an angle of 60° in the same plane. Since the triaxial fabric is a special structure with three interwoven yarn systems, it has good structural stability of the fabric and the same mechanical properties of force in all directions, so that the force acting on the fabric is dispersed in On the three axes, the fabric's ability to withstand loads is greatly enhanced. The fabric's performance indicators such as bursting strength, tear resistance and breaking strength are higher than those of two-axis fabrics, and it has uniform force in any direction. Advantages: high diagonal stretch resistance, great squeezability, and better fatigue resistance

Carbon fiber spread tow triaxial fabrics are lighter and thinner. When the final composite product is limited by weight, thickness and mechanical properties design, carbon fiber spread tow triaxial fabrics better reflect the designability.

And because the three yarns of the triaxial fabric are interlaced and woven with each other, the yarns in the three directions refract light at different angles, giving the fabric a three-dimensional effect, making it more beautiful and unique.

| Yarn width | 8,12,16,20mm |

| Weight | 120,150,200gsm |

| Thickness | 0.10, 0.15, 0.20mm |

| Carbon fiber | T700 |

Characteristics of triaxial reflective surface fabric:

Fiber-reinforced composite materials are composed of fiber reinforcement and resin matrix. They have the advantages of small specific gravity, excellent mechanical properties and strong designability, and are widely used in the aerospace field. The fiber reinforcement in composite materials serves as the main load-carrying body, and its mechanical properties determine the mechanical properties of composite materials to a large extent. Fiber reinforcements are generally composed of unidirectional or bidirectional woven fabrics and resin matrices. In these fabrics, fiber yarns are interspersed with each other at an angle of 0° or 90° to form a densely packed two-dimensional plane. The surface density of the fabric is relatively high and The fiber yarns have many overlapping points, which is not conducive to the full penetration of the resin matrix.

Three-way fabric is formed by interweaving three groups of yarns in a plane at a specific angle (60°).

It is a kind of flat fabric. Due to the higher symmetry of the weaving structure and the good isotropy of the fabric, it can disperse the load more effectively when it is stressed, making the mechanical properties of the three-way fabric better than ordinary fabrics. The yarn in the three-way fabric The threads are intertwined at specific angles, allowing the existence of holes in the fabric to effectively reduce the surface density of the fabric. These characteristics make composite materials with three-dimensional fabric reinforcement more excellent.

It is lighter and has better overall performance and is widely used in the fields of sporting goods and aerospace.

| Yarn width | 1.5, 2mm |

| Distance of the holes | 3±0.5mm, 4±0.5mm |

| Weight | 100,130gsm |

| Carbon fiber | T700 |

APPLICATIONS