-

-

3K - 200gsm - Plain Carbon Fabric

- Code:TC-CF-3KC200P

- Material:100% Carbon Fabric

- Weight:200GSM

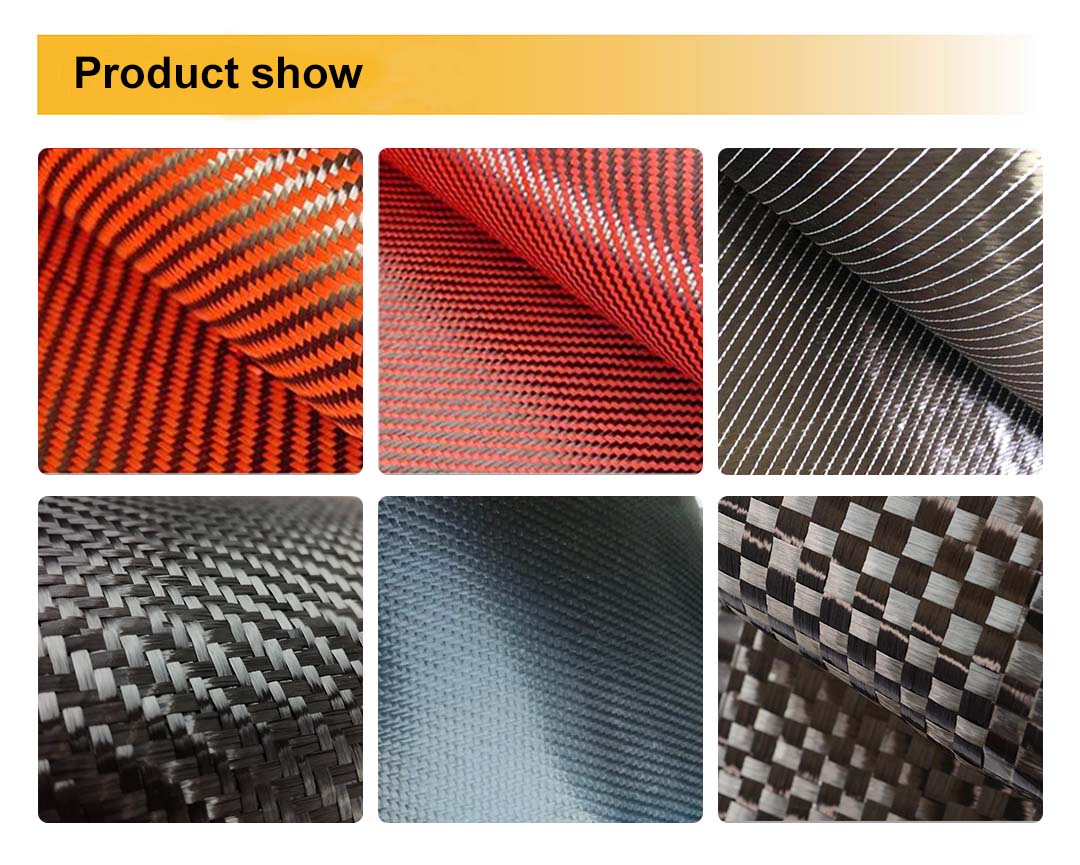

- Function:exterior and interior fabric for sports equipment, automobiles, furniture decoration, etc.

- Color:Black

- Weave:Plain

- Width:10~150CM

SEND INQUIRY

Product Properties

It has strong durability and corrosion resistance, which are two commendable properties of carbon fiber reinforced cloth.

High tensile strength, light weight, carbon fiber is actually much stronger than steel in terms of strength-to-weight ratio, the weight of carbon fiber is only about one-fifth of that of steel, so that is to say, under the same weight, carbon fiber The strength is about five times that of steel.

Low thermal expansion coefficient, carbon fiber has a high resistance to temperature changes, which means that the carbon fiber gripper does not expand or contract at different temperatures. For this reason, it is ideal for factory or assembly line placement.

High modulus

Very high stiffness

Excellent tensile and bending properties

High impact resistance

Thermal resistance

Good shock absorption

Conductivity

Support weave lock customization, more stabilized/fixed and less flexible/elastic … so it won't create scrap in production

Material: |

100% carbon fiber | Yarn (warp): | 3k carbon fiber |

| Pattern: | Plain | Yarn (weft): | 3k carbon fiber |

| Weight : | 200gsm | Width: | 10-150cm |

| Density(warp): | 5/10mm | Thickness: | 0.3mm |

| Warp tensile strength | >800N/25mm | Weft tensile strength | >600N/25mm |

| Density(weft): | 5/10mm | Color: | Black |

Material: |

100% carbon fiber |

| Pattern: | Plain |

| Weight : | 200gsm |

| Density(warp): | 5/10mm |

| Density(weft): | 5/10mm |

| Yarn Count(warp): | 3k carbon fiber |

| Yarn Count(weft): | 3k carbon fiber |

| Width: | 10-150cm |

| Warp tensile strength | >800N/25mm |

| Weft tensile strength | >600N/25mm |

| Thickness: | 0.3mm |

| Color | Black |

Product Description

The characteristics of plain weave carbon fabrics are that the warp and weft are interwoven in a regular pattern, that is, the warp and weft are interlaced every other yarn, so there are many interlacing points, and the fabric is firm, wear-resistant, stiff, and flat, but the elasticity is small, the gloss is general. Because the fiber bundle of this carbon fiber cloth has been in a state of ups and downs, there are many fiber bending points, and the elongation rate is high during the stretching process. At the same time, due to the position of the interlacing point of two adjacent warp yarns and two adjacent weft yarns, eyelets appear due to the sliding of the fiber bundle. Due to the difference in reflected light from the fiber bundles in the warp and weft directions, the plain weave fiber cloth has a lattice-like appearance, similar to a chessboard.

Plain weave carbon fiber cloth is mainly used for:

1. For aerospace: fuselage, rudder, rocket engine casing, solar panels, etc.

2. For sports equipment: auto parts, motorcycle parts, fishing rods, feather rackets, etc.

3. Used in industry: engine parts, reinforcing materials for concrete structures, drive shafts, and electrical components, etc.

4. For fire protection: suitable for the production of special high-grade fireproof clothing for troops, firefighting, steel mills, etc.

5. Reinforcement of concrete and metal pipes.

Properties of Bidirectional fabric

The advantages of bidirectional carbon fabric are:

•It has very good mechanical properties and has very good performance in different directions • Can withstand tensile and compressive forces in different directions; •It can be superimposed in different directions as needed to meet different engineering requirements

The disadvantages of bidirectional carbon fabric are:

•Compared with the unidirectional carbon fabric, the strength and stiffness of the bidirectional carbon fabric are lower • Since there are both wrap and weft fiber tows, carbon fabric is easy to damage and breakage in both directions during use

| Content: | 100% carbon fiber |

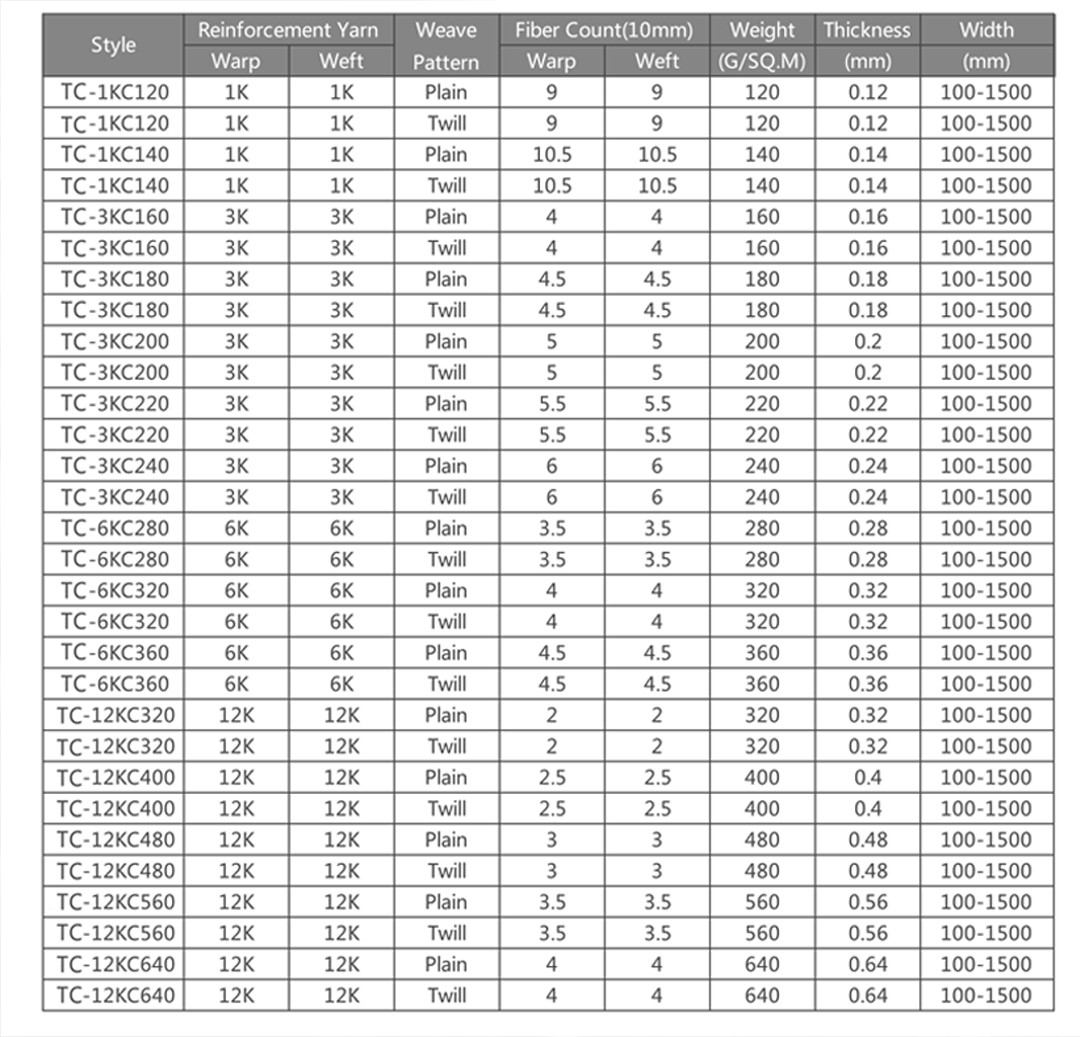

| Specification : | 1k-12k, 120-640gsm |

| Color: | Black |

| width: | 10-150cm, customized width is available |

| Feature: | High tensile strength, high modulus, strong durability and corrosion resistance, low thermal expansion, high stiffness, high impact resistance, conductivity, good shock absorption |

| MOQ: | 100m |

| Meet standard : | AATCC/ASTM, EN, ISO, GB, AS |

| Application : | Used in car, trains, transportation, building reinforcement, sports equipment, aerospace, drive shafts, Reinforcement |

Similar Series Technical Data