-

-

私たちに 関しては

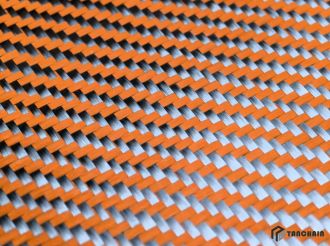

- 有限会社は研究開発、生産、販売を一体化したハイテク企業であり、高強度、難燃性、断熱性、高温耐性製品に集中しており、主にプレ酸化繊維、炭素繊維、アラミド繊維、ポリテトラフルオロエチレンなどで編んだ糸、生地などの機能性紡績製品を含み、製品は工業、交通、自動車、防護などの業界に広く応用されている。8年余りの極端な防護と労働保護応用革新製品の生産経験により、tanchainはその顕著な調達と技術的優位性により、すでに中国の技術織物市場のリードサプライヤーの1つに発展した。私たちは完全な産業チェーンと厳格な品質管理システムを持っています。 タンチェーンは国内外の一流原材料サプライヤー数十社の中から原材料サプライヤーを慎重に選び、長期供給協定を締結し、大量の良質原材料を適時に獲得することを確保し、また私たちの製品品質の根本的な保証でもある。 私たちは国内外に高基準の現代化学工場を設立し、国内外の会社から一流の仕事経験を持つ管理者と技術者を招聘して、私たちの製品が独自の技術優位性と市場競争力を持つことを確保しました。 良い製品は私たちを国内外の市場で大量の顧客を獲得させ、これらの良質な顧客は私たちの会社の貴重な資源です。優れた顧客層はフィードバックを提供し、製品の機能と品質を向上させてくれます。 会社設立当初から品質管理部門を設立し、会社の理事長は品質管理を非常に重視していた。私たちは大量の資金を投入して私たちの製品の品質を確保して、これは私たちが市場で長期的に立脚する基礎です。工場は原材料の工場への進出、生産加工から完成品までの全過程を管理し、制御する。各プロセスは科学的な規範に従い、改善され続けています。 私たちの使命は、高品質の糸、織物、その他の紡績製品を提供することによって、お客様のニーズを満たすことで、市場で公認されている主要なサプライヤーになることです。デルの使命は、卓越したカスタマーサービス、販売、製造、およびすべての従業員のチームワークによって実現されます。デルは、お客様、従業員、コミュニティ、ステークホルダーとの関係において、誠実で公平で正直な伝統を維持し続けます。

タチカン、2024年JEC複合材料展に出展

糸とは何ですか?

カーボンファイバープリプレグの保存温度を知っていますか?

航空宇宙分野における弾性率と高弾性炭素繊維の応用とは?

炭素繊維とスチールの主な違いは何ですか?

炭素繊維アプリケーションの知識:炭素繊維が軽量グリッパーを備えたロボットに適している理由は何ですか?

炭素繊維一般的な応用製品、炭素繊維板の優れた特性

航空宇宙における炭素繊維の技術状況と研究の進展

カーボンファイバープリプレグとは? -カーボンプリプレグの製造工程は

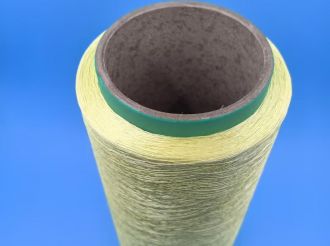

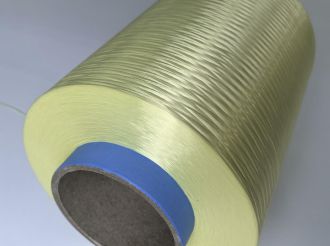

ケブラー繊維の代替品:工業用糸と糸。

●炭素繊維自動車部品

炭素繊維複合部品の使用は、主に次の考慮事項に基づいています。

一つは、軽量なボディのためです。炭素繊維の密度は、炭素鋼の50%の軽量化に比べて、マグネシウム/アルミニウム合金構造の30%の軽量化に比べて、低いです;

その二、高い融合自由なモデリング、強力な設計性、合理化と曲面を実現することができ、部品や金型投資の種類を減らすことができます;

第三に、生産効率の向上です。プレスと溶接の代わりに金型を押すと結合プロセス、生産ライン、金型と治具の投資を節約;

第四に、自動車の安全性能を向上させる。炭素繊維は、高い疲労強度(設計負荷の70 ~80%まで)を有し、軽量化後に重心が低下し、運転安定性が高くなります。

また、炭素繊維の衝突エネルギー吸収能力は、鋼の6 ~ 7倍、アルミニウムの3 ~ 4倍である。5つ目は、車の快適性を高めることです。より高い振動減衰、車の全体的な騒音低減は明らかな効果を有し、乗客の快適さをより良くします。

ハイエンド商用車原车から、近年でファンが多く、新エネルギー车のアプリケーションのカーボンファイバー部品足音が止めないなど无锡新素材で聡明さ、エネルギー産業自動車製造の要求に基づきカーボンファイバー炭素繊維電力电池box体は典型的な応用例で、新エネルギー自動車でダイエットなどなんで、耐衝撃性を効果的に新エネルギー車の性能を向上させました。

●高速列車の中で炭素繊維

高速鉄道の軽量化ソリューションは、常に2つの問題に焦点を当ててきた。1つは、軽量材料には十分な安全性が必要であること。もう1つは、安全確保を前提に軽量化を図り、大容量化、高効率輸送を実現することです。

時速400キロ以上の新幹線、2階建ての列車から時速600キロの高速リニアモーターカー、高速鉄道などの鉄道車両は、高速化、効率化、グリーン化、知能化などの目標に向かって発展してきた。その中でも、軽くて丈夫なボディ素材が重要な役割を果たします。原材料选定车体、力が硬くなっ疲労抵抗耐食性と成形火の公演出演どんどん最適化し、炭素繊維アスファルト合材の利点を重さは軽いし、備えて冲撃削減・リフト負荷高耐候性、高い信頼性高い可用性、高い生活、メンテが関心を集めた。しつつ

炭素繊維のタクシー運転手操作パネル、炭素繊維シート部品プレート炭素繊維状況など高速鉄道などで使われる炭素繊維複合素材であると軌道車両1时间の割合などで聡明无锡新素材は顔技術水準高さもますます求められる事実上も駆動国内の炭素繊維にもアスファルト合材より速いスピードで申請した。

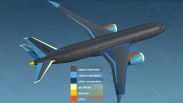

●カーボンファイバー製航空機部品

よりも実力が炭素繊維複合素材だ高が硬く、良好な疲労抵抗と耐腐食、、をデザインできるよう效率化を推進し、航空機の安全を高めるだけでなく経済、慰めや环境も燃料効率を大幅に向上させる航空機は現在、民間航空機アプリケーションの相当部分を実施。

同時に、航空機への炭素繊維複合材の使用は、新たな技術的課題を提起しています。炭素繊維複合構造は、従来の金属構造と比較して異方性を有し、その脆性により、荷重による変形、損傷機構、破壊モードなどの点で従来の金属材料と大きく異なる。このような接続分析、安定性、損傷許容性、可燃性、大きな開口部、雷保護、耐火性、防氷、層間分析などの一連の技術的な問題は、突破する必要があります。

画期的な機体および推進技術は、空気抵抗を低減し、空気力学、構造および材料の全体的な最適化において燃料を節約するために使用されます。しかし、音の超音速と超高速で飛行するとき、体の構造の高温効果は明らかであり、炭素繊維のような先進的な複合材料の統合構造設計を必要とするだけでなく、それらを軽量化し、損傷に強く、高温になります。

機体だけでなく、機体内部の材料も厳しい。炭素繊維航空席フレーム板无锡之仓と酒を新素材科技有限公司によって提供される民间航空机、民间公司一定タイプまた席体重を大幅に削减たりするをクリアして6 ~ 8年高域圧力のクセがある素材もさのため、全とても高い要求を提案した実用化に優れた炭素繊維複合素材である。

メタアラミドは難燃性に優れ、インテークマニホールドに熱風を供給するホースやターボチャージャホースなど、ボンネット下でフレキシブルな高温ホースに使用できます。メタアラミドはエンジンルームの過熱を防ぎ、ラジエターホースが破裂し、ワイパーが故障するのを暑い天候でも防ぎます。

メタアラミドによるレース保護は、レース業界が火災の脅威のあらゆる側面を改善するのに役立ちます。fr meta armidを使用したレーシングスーツや衣類は、この安全性向上の中心にあります。

この保護は長続きします。保護服、下着、靴下、手袋のいずれの場合でも、異常な難燃性や摩耗を防ぐことができます。

メタアラミド繊維のレース用品は難燃性を持っています。炎にさらされると空気中で燃えたり溶けたりしません。メタアラミドは炭化して高温になると濃くなるからだ。それは熱源と皮膚の間の熱障壁を形成します。この独特の高温応答は、火災時の貴重な脱出時間を提供し、着用者を怪我から守るのに役立ちます。

炭素繊維はスポーツ用品分野に広く応用されており、多くの利点がある。

主なアプリケーションのいくつかを次に示します。

1.自転車:

−フレーム製造:炭素繊維は自転車フレームを製造するのに理想的な材料である。それは非常に軽くて非常に頑丈なフレームを作ることができて、自転車の全体的な重量を大幅に軽減して、騎手をもっと乗りやすくして、特に坂を登って長距離を走る中で。例えば、いくつかのハイエンドレーシングカーは炭素繊維フレームを使用して、より高い速度とより良い操縦性能を追求している。

-部品:フレームのほか、ハンドル、シートパイプ、車輪などの自転車の他の部品にも炭素繊維が使用されています。炭素繊維ハンドルはより良い剛性と操作性を提供することができ、座管は騎手の必要に応じて調整することができる。それは軽くて、自転車にあまり負担をかけません。炭素繊維車輪は高強度と低回転慣性を有し、自転車の加速性能と走行速度を高めることができる。

2.ゴルフクラブ:

-シャフト:カーボンファイバーシャフトゴルフクラブの人気が高まっている。従来の金属棒に比べて炭素繊維棒は軽く、選手のスイング負担を軽減し、スイング速度を向上させることができ、それによってショットの距離と精度を高めることができる。また、炭素繊維は高い減衰特性を持ち、打撃時の部分振動を吸収し、選手を快適にすることができる。

-クラブヘッド:カーボンファイバーはゴルフクラブのクラブヘッドにも使用される。炭素繊維材料はクラブヘッドの強度と安定性を強化するために使用することができ、クラブヘッドが打撃時に衝撃力によりよく耐え、変形と損傷の可能性を低減することができる。

3.釣り竿:

-主な構造:炭素繊維釣竿は強度が高く、弾性率が高く、重量が軽いという特徴があり、大きな引張と曲げ応力に耐えられ、重量が軽く、釣り人の長時間の把持と操作に便利である。海上漁でも淡水漁でも、炭素繊維釣り竿は異なる漁獲シーンのニーズを満たすことができる。

-竿先:竿先は釣竿の重要な部品であり、感度と柔軟性に対する要求が高い。炭素繊維材料の応用はロッドの先端をより鋭敏にすることができ、魚のフックの信号を正確に感知し、釣りの成功率を高めることができる。同時に、炭素繊維の柔軟性は、磁極先端が外力を受けたときに破断しにくいことを保証することもできる。

4.棚:

-テニスラケット:炭素繊維テニスラケットは良好な剛性と弾力性を持ち、打撃時に強大な動力支持と良好なボールコントロール性能を提供することができる。炭素繊維材料はテニスラケットの重量分布をより均一にし、ラケットの安定性と平衡性を高め、選手がボールを打つ時により正確で力強いものにすることができる。

-フェザーラケット:フェザーラケットにとって、炭素繊維の応用はラケットの重量を軽減し、スイング速度と柔軟性を高めることができる。同時に、炭素繊維の高強度特性はラケットが高速揺動と頻繁な打撃の下で変形や損傷しにくいことを保証し、ラケットの寿命を延長することができる。

-キムチボールラケット:炭素繊維キムチボールラケットは軽くて弾力性があり、選手により良い打撃体験を提供し、選手が打撃をする時により便利になり、技術レベルをよりよく見せることができる。

5.氷雪運動器材:

-スキー板:炭素繊維スキー板は丈夫で軽量で、スキー板の剛性を保証すると同時に全体の重量を軽減することができ、スキー者が滑る過程でより柔軟で自由で、速度と方向を制御しやすい。また、炭素繊維は良好な制振性能を有し、スキーヤーの滑走中の振動を減少させ、快適度を高めることができる。

-スケート靴:炭素繊維はスケート靴の構造強度と安定性を強化し、スケート靴を高速滑りと急旋回時に良好な性能を維持させ、スケート靴の変形と損傷を減少させることができる。同時に、炭素繊維の軽量特性はスケート靴全体の重量を軽減し、選手の滑走速度を高めることもできる。

6.その他のスポーツ用品:

-運動靴:一部のハイエンド運動靴は靴底、靴の表面などの部位に炭素繊維材料を使用している。靴底では、炭素繊維は良好な支持と安定性を提供し、足の疲労を減らすことができる、靴の表面には、炭素繊維が靴の表面の強度と通気性を高め、スニーカーの快適性と耐久性を高めることができます。

-ヘルメット:炭素繊維ヘルメットは軽量で強度が高く、選手の頭部を保護することができ、同時に頭部の負担を軽減し、快適さと表現を高めることができる。例えば、炭素繊維ヘルメットは自転車、オートバイ、ローラースケートなどのスポーツに広く応用されている。

-アーチェリー器材:炭素繊維は弓矢などのアーチェリー器材の製造に用いることができる。炭素繊維弓は高強度と弾性を有し、安定したアーチェリー性能を提供することができる、炭素繊維矢印は軽量でまっすぐで、矢の飛行速度と精度を高めることができる。

炭素繊維は建築補強分野で広く応用されており、

主に次のような点に表れています。

一、優勢

1.高強度、高剛性:炭素繊維材料の強度は伝統的な建築材料、例えば鋼材よりはるかに高い。構造重量を大幅に増加させることなく、建物の荷重力を大幅に向上させることができます。

2.耐食性:炭素繊維は優れた耐食性を有し、酸塩基などの化学物質の腐食を受けない。さまざまな劣悪な環境での建築補強に適しています。

3、施工の便利さ:炭素繊維布或いは炭素繊維片の材質は軽くて、柔らかくて、切断と貼り付けが容易で、施工過程は簡単で迅速で、施工周期を大幅に短縮することができる。

4.建築外観に影響なし:炭素繊維材料は構造表面に非常に薄く貼り付けることができるため、建築外観に与える影響は小さい。

二、シーンを適用

1.古い建物の補強:歴史が古く、構造が壊れた建物、例えば梁、柱、床などに対して、炭素繊維を使って補強し、その安全性と耐久性を高めることができる。

2.地震被災地の建築物の修復:地震などの自然災害が発生した後、炭素繊維は損傷した建築物を迅速に修復し、その使用機能を回復することができる。

3.橋梁補強:橋梁は長期使用中に亀裂、変形などの問題が発生する可能性がある。炭素繊維は橋構造を効果的に強化し、その担持能力と安定性を高めることができる。

4.特殊建築構造の補強:例えば、大スパン空間構造と高層構造、炭素繊維はその高強度と軽量化の要求を満たすことができる。

III、施工技術

1.表面処理:補強構造の表面に対して清掃と研磨を行い、油汚れ、ほこり、緩いコンクリートなどを除去し、炭素繊維と構造表面に良好な付着力を確保する。

2.プライマーの塗布:構造の処理表面にプライマーを塗布して、炭素繊維と構造の間の接着力を強化する。

3.炭素繊維の貼り付け:設計要求に基づいて炭素繊維布または炭素繊維シートを構造表面に貼り付け、専用工具で圧縮し、炭素繊維と構造の密着を確保する。

4.表面保護:炭素繊維を貼り付けた後、必要に応じて表面保護処理を行うことができ、例えば防火塗料、防腐塗料などを塗って、炭素繊維の耐久性と安全性を高めることができる。

造船における炭素繊維の応用は徐々に成熟し、造船業において重要な役割を果たしている。

炭素繊維複合材料の応用範囲は、初期の小型哨戒艦や揚陸艦から掃海艦や軽護衛艦などの大型船舶に広がっている。技術の進歩に伴い、艦船の長さと排水量は増加し続け、80-90メートルの全複合材料海軍艦艇が使用されている。アメリカ、ヨーロッパ、日本などの国と地域は炭素繊維複合材料船の建造においてリードしており、ステルス試験船や軽駆逐艦などの高性能船舶の建造に炭素繊維を応用することに成功した。これらの艦艇は高い安定性と迅速性を持つだけでなく、ステルス、対潜、反機雷能力も持っている。

近年、中国は炭素繊維複合材料の応用においても大きな進展を遂げている。研究開発チームの努力によって、国内のハイエンド炭素繊維織物複合材料の高速客船における模範的な応用が突破され、造船における炭素繊維複合材料の応用が新たな高さに達したことを示している。また、上海タン鎖の炭素繊維製品は船舶関連設備の製造に初歩的に応用され、造船分野での炭素繊維の応用が一定の規模になったことをさらに証明した。

炭素繊維複合材料の応用は船舶の性能を高めるだけでなく、船舶の重量と燃費を下げ、船舶の環境保護性と経済性を高めるのに役立つ。例えば、北欧軍艦における炭素繊維マストの応用はかなり成熟している。この材料は船舶の重量を軽減するだけでなく、燃料消費を低減し、船舶の総重量を他の機能により多く分配することができる。

以上より、造船分野における炭素繊維の応用はすでに試験段階から実用化に転じ、船舶の性能と環境保護性を高めただけでなく、コストと持続可能性の面でも優位性を示し、将来の造船分野において炭素繊維が広大な発展の見通しを示した。

消防士防護服の基本的な構成部分として、難燃性に対する要求は特に重要である。間位アラミド繊維の出現により消防服がグレードアップされた。消防士は革、厚い羊毛、キャンバスだけの重い消防服を完全に除去し、織物や裏地から性能を高めることができるようにした。

現在、消防士、消防服、間位芳綸有色繊維から作られた消防服は各種消防システムに使用されている。間位芳綸カラー繊維には武装警察森林消防士の制服も付いている。

その優れた性能のため、間位芳綸は冶金、建築、造船、石油、化学工業、林業、消防、軍事などの分野に広く応用され、各種特殊防護服を加工する最適な選択となっている。

Firefighters have a heavy load to bear — their turnout gear shouldn’t

add to it. So Aramid fibers help manufacturers create fire resistant

liners, outer shells, and accessories that not only stand up to the

thermal hazards they may face, but also help them get the job done

without getting in the way of mobility.

Unlike other materials and fibers available, gear and

accessories made with meta aramid fiber are inherently flame-resistant and

won’t melt, drip, or support combustion in the air. And the thermal

protection off is permanent — its superior flame

resistance cannot be washed out or worn away. Para aramid helps

manufacturers enhance the overall durability and strength of lightweight

turnout gear outer-shell-and-thermal-liner systems. It is five times

stronger than steel on an equal weight basis, yet is lightweight,

comfortable, and thermally protective.

この2つの革新的な繊維は、ほとんどの分岐ギアの各層に存在し、究極の保護を提供します。

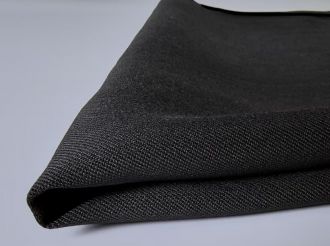

●ハウジング

Meta aramid and Para aramid fibers are engineered together and sometimes

with other high-temperature fibers to form materials that help stand

up to heat, stay strong, and protect the inner components. Para aramid

filament is engineered into premium fabrics to help reduce fabric

profile while strengthening fabrics to new levels of performance.

●ぼうしつそう

Fabrics made of meta aramid fiber and non-wovens help

the most trusted and reliable moisture barrier manufacturers provide

strong flame-resistant substrates for their liquid-impermeable films.

The moisture barrier helps protect against the intrusion of water,

chemicals, and viral agents. These barriers are also breathable, which

allows metabolic heat to escape and helps reduce the overall heat stress

during strenuous activities.

●だんねつライナ

Meta aramid and Para aramid fiber batts and the meta aramid non-wovens are combined

with face cloths made with meta aramid and para aramid fiber to help provide

durable, flexible, heat-insulating components. Thermal liners made with

multi-layer meta aramid non-wovens are among the thinnest, most

flexible, most breathable components on the market. Face cloths using para aramid filament yarns help reduce surface friction, improving overall

garment mobility. Water-wicking or -repellent finishes on individual

layers improve moisture management and reduce garment-drying time.

技術が急速に発展した時代、炭素繊維はその優れた性能で航空宇宙と航空機製造分野の輝かしい星となった。

炭素繊維は軽量だが非常に強靭であり、航空宇宙産業に強力な動力を注入している。航空機製造では、機体の重量を大幅に軽減し、より効果的に青空を飛ぶことができるようにしています。想像してみて、炭素繊維で作られた飛行機は、頭のいい鳥のように、雲を通り抜けやすい。

航空宇宙分野では材料に対する要求が非常に厳しく、炭素繊維はこれらの要求を完璧に満たしている。非常に高い強度を持ち、大きな圧力と衝撃に耐えることができ、飛行安全のために堅固な保護を提供しています。同時に、その優れた耐食性は航空機が様々な劣悪な環境で優れた性能を維持できることを保証している。

炭素繊維の応用は航空機の性能を高めるだけでなく、エネルギー消費を低減し、環境保護に役立つ。それは航空宇宙分野に新たな発展のチャンスをもたらし、より広い未来を切り開いた。炭素繊維を選ぶことは革新と卓越を選ぶことである。私たちは一緒にもっと高い空に飛んで、宇宙の果てしない奥義を探求しましょう。

アラミド繊維は、弾道と耐stab-resistantボディアーマーでの使用で知られており、何千人もの命を救うのに役立つと信じられています。軽量で非常に強いため、さまざまな衣類、アクセサリー、機器をより安全に、より切断しにくく、より耐久性のあるものにするために使用できます。アラミド繊維は、ガラスの破損、金属の破片、鋭い機械、その他の危険に対する優れた切断保護を産業労働者に提供します。

●工業用難燃性衣類

メタアラミドは、石油化学、化学、電力、ガスなどの産業用防護服に使用され、難燃性と耐ノック性に優れています。メタアラミドと他の高性能繊維をブレンドした防護服は、より危険な作業環境に対応します。

●レーススーツ

メタアラミド繊維を使用したレーススーツは、耐火性、耐熱性に優れているだけでなく、腐食性ガスや酸性液体にも強く、レーサーの全身を保護します。

●溶接スーツ、炉のスーツ

電気溶接や金属製錬に従事する作業者は、いつでも衣服に火花や溶融金属が飛びつき、皮膚にやけどを起こしたり、衣服に着火して火災を起こすなど、より深刻な危険を引き起こす可能性があります。冶金作業は長時間高温にさらされ、通常の材料の衣服は簡単に変更できます。脆く、耐用年数を短縮します。メタアラミド製の溶接スーツや炉スーツは、永続的な難燃性、金属の水しぶき、不密着性などの特徴があり、洗濯や長時間の着用による保護性能の低下はありません。

これらの優れた特性により、メタアラミド繊維は国内外の市場で広く認知され、受け入れられています。メタアラミド繊維で作られた防護服は、あらゆる階層の人々の生活を守っています。

自動車、製造、建設、航空宇宙、電子産業において、クラス最高の切断保護と作業危険に対する耐火性を提供します。その耐カット性と耐火性は、二重の危険からの保護が必要な場合に最適です。