-

Application of Aerogel Materials in Modular Buildings

-

Aerogel new building materials have gradually become "the most promising high-performance materials in the construction field".

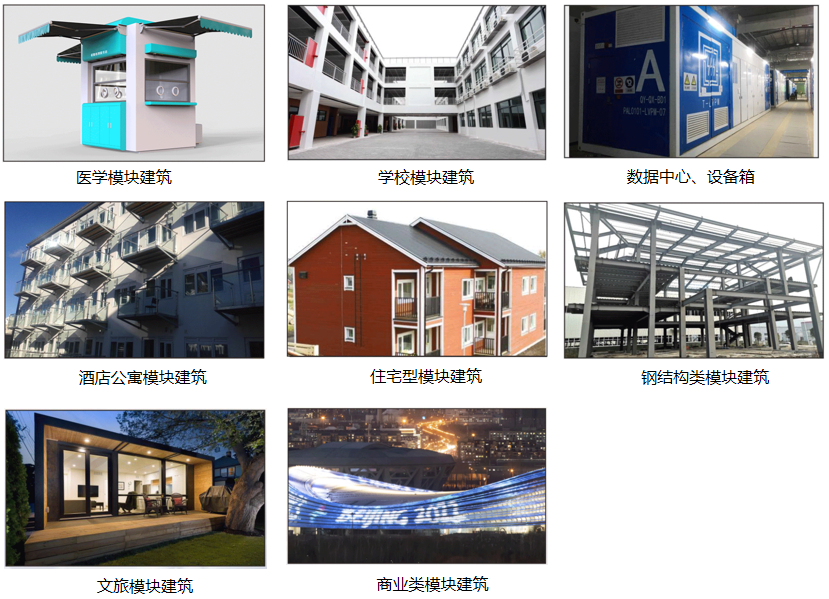

Modular building is considered to be an assembly technology in the field of construction. The construction of houses mainly uses prefabricated modular components to assemble, which has the advantages of dexterous assembly, energy saving, environmental protection and simple construction.

In the entire modular building industry, the advantages of modular buildings are fast construction speed, less restricted by climatic conditions, labor saving, and can effectively improve construction quality.

Aerogels

SiO2 aerogel is a nanoporous solid material whose main component is ultrafine particles. The material has the characteristics of low thermal conductivity, low density, large specific surface area, high porosity, and small particle size, and is currently regarded as the lightest solid material. Due to the special physical structure of aerogel, it has strong fire resistance, heat insulation and other properties. With the deepening of the application research of aerogel in the field of construction, aerogel new building materials have gradually become the "most promising" high-performance materials in the field of construction.

Aerogel Modular Building Applications

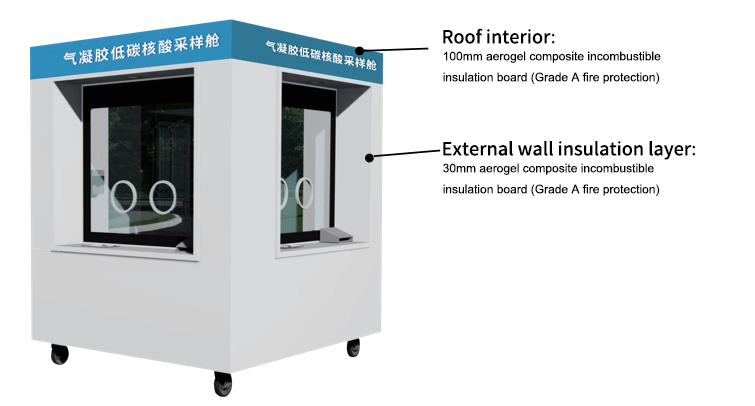

The aerogel low-carbon nucleic acid sampling cabin series products, through the excellent thermal insulation performance of aerogel materials, can achieve high efficiency and energy saving and 60% carbon reduction, and at the same time meet A-level fire protection, making nucleic acid sampling work safer and more efficient.

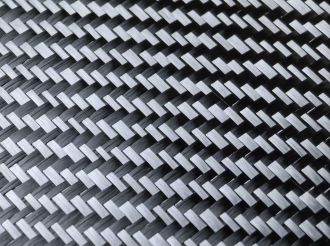

Production process diagram

Using aerogel composite non-combustible insulation board inside the sampling chamber

Sampling cabin ceiling using aerogel insulation medium coating

The ceiling of the sampling cabin uses aerogel insulation medium coating + aerogel composite non-combustible insulation board

Sampling cabin sandwich panel using aerogel composite non-combustible insulation board

Aerogel Modular Building Applications

Aerogel New Building Materials

NO1. Aerogel composite non-combustible insulation board

External wall insulation - (hot in summer and cold in winter and other areas)

Aerogel composite non-combustible thermal insulation board is a non-combustible thermal insulation board formed by adding fillers such as silica aerogel powder, compounding a small amount of polystyrene particles, and molding with inorganic materials. It is used for building wall insulation, external wall insulation, building roof insulation, color steel and roof sandwich panels, etc.

Traditional organic thermal insulation materials (such as EPS board, XPS board and polystyrene board, etc.), the highest fire rating can only reach B1 level, the application in construction is limited, and the material is easy to age under natural conditions, while the aerogel composite is incombustible The fire rating of the thermal insulation board can reach Class A, and the flame retardant effect is good.

Traditional inorganic thermal insulation materials (such as glass wool, rock wool board, etc.) contain fibers, which are not friendly to workers during construction, and the product has poor rigidity, which is easy to absorb water and cause problems such as bubbling and falling off, while aerogel composite non-combustible thermal insulation board belongs to low Carbon environmental protection product, the carbon emission is only 60% of rock wool, and the product has a certain rigidity, and the base material does not contain fiber, which is harmless to the human body.

The specific advantages are as follows:

(1) Thermal conductivity as low as 0.043W/(m*K);

(2) Real Class A fire protection;

(3) The product has a closed-cell structure with low volume water absorption;

(4) Long service life and aging resistance;

(5) Good mechanical properties.

NO2. Aerogel Thermal Insulation Coating System

External wall insulation - (hot summer and warm winter and hot summer and cold winter areas)

It is an aerogel thermal insulation coating system composed of aerogel thermal insulation middle coating, primer and topcoat. It has the advantages of thermal insulation, light weight, safety and fire protection, environmental protection and long service life.

It can be applied to the energy-saving renovation of building facades and roofs. The products have the advantages of thin thickness, good thermal insulation effect, light weight, safety and environmental protection, and can effectively reduce building energy consumption. Especially compared with traditional thermal insulation materials, it has obvious advantages in thickness, construction convenience and safety.

(1) At present, the requirements for building energy conservation are becoming more and more stringent. Taking the requirements of GBT50378-2019 "Green Building Evaluation Standards" as an example, two-star and three-star buildings require that the thermal performance of the envelope structure be increased by 10% and 20% respectively. The drawbacks of meeting the energy-saving requirements by thickening the external thermal insulation of the external wall have gradually emerged, such as cracking and falling off of the external wall thermal insulation layer, leakage of external thermal insulation, and frequent occurrence of fires at the construction site of external thermal insulation.

(2) According to the thermal requirements of different climatic zones, selecting suitable thermal insulation materials can not only achieve the purpose of energy saving and thermal insulation, but also prolong the life of the building. In areas with hot summers and warm winters, in order to meet the energy-saving requirements, the design institute usually designs and uses 30mm~40mm vitrified microbead thermal insulation mortar on the outer walls to meet the energy-saving design requirements.

(3) By comparison, the thermal resistance of the 2mm aerogel thermal insulation coating system can completely replace the 40mm vitrified microbead thermal insulation mortar for energy-saving design. At the same time, compared with the traditional thin plastering system for external thermal insulation of polystyrene board exterior walls, the aerogel thermal insulation coating system has the advantages of integration of thermal insulation and decoration, and simple construction, which can solve the problem that traditional thermal insulation boards are easy to absorb water and fail, and the thermal insulation layer falls off. Phenomenon.

NO.3 Aerogel waterproof and thermal insulation membrane

Aerogel waterproof and thermal insulation membrane is an integrated waterproof and thermal insulation material. It is composed of reflective aluminum film + aerogel insulation layer + self-adhesive waterproof substrate + release film material. The product has the advantages of waterproof, sun protection, heat insulation and cooling, convenient construction, long service life, good flame retardant performance, good heat resistance, high bonding strength, and green environmental protection.

One construction to solve the two major problems of waterproof and heat insulation such as metal roof and building roof leakage.

Application advantages:

-

Anti-ultraviolet, isolating solar thermal radiation

The aluminum foil on the surface layer provides good anti-ultraviolet aging and insulation from solar heat radiation.

-

Simple construction

It is easy to use and can be directly bonded after cleaning the building roof surface; the construction is simple, the operation is safe, the construction period is short, the efficiency is high, and no maintenance is required after molding.

-

High bonding strength

Compared with ordinary self-adhesive coils, the bonding strength is increased by 80%. The longer the bonding time, the better the bonding effect.

-

The flexible waterproof layer can adapt to the thermal expansion and contraction deformation of the roof and the deformation of the wind load.

-

It has a wide range of uses and can be firmly bonded to cement base surfaces and various metal surfaces.

High tensile strength, large elongation, and strong adaptability to the shrinkage, deformation and cracking of the base layer.