-

-

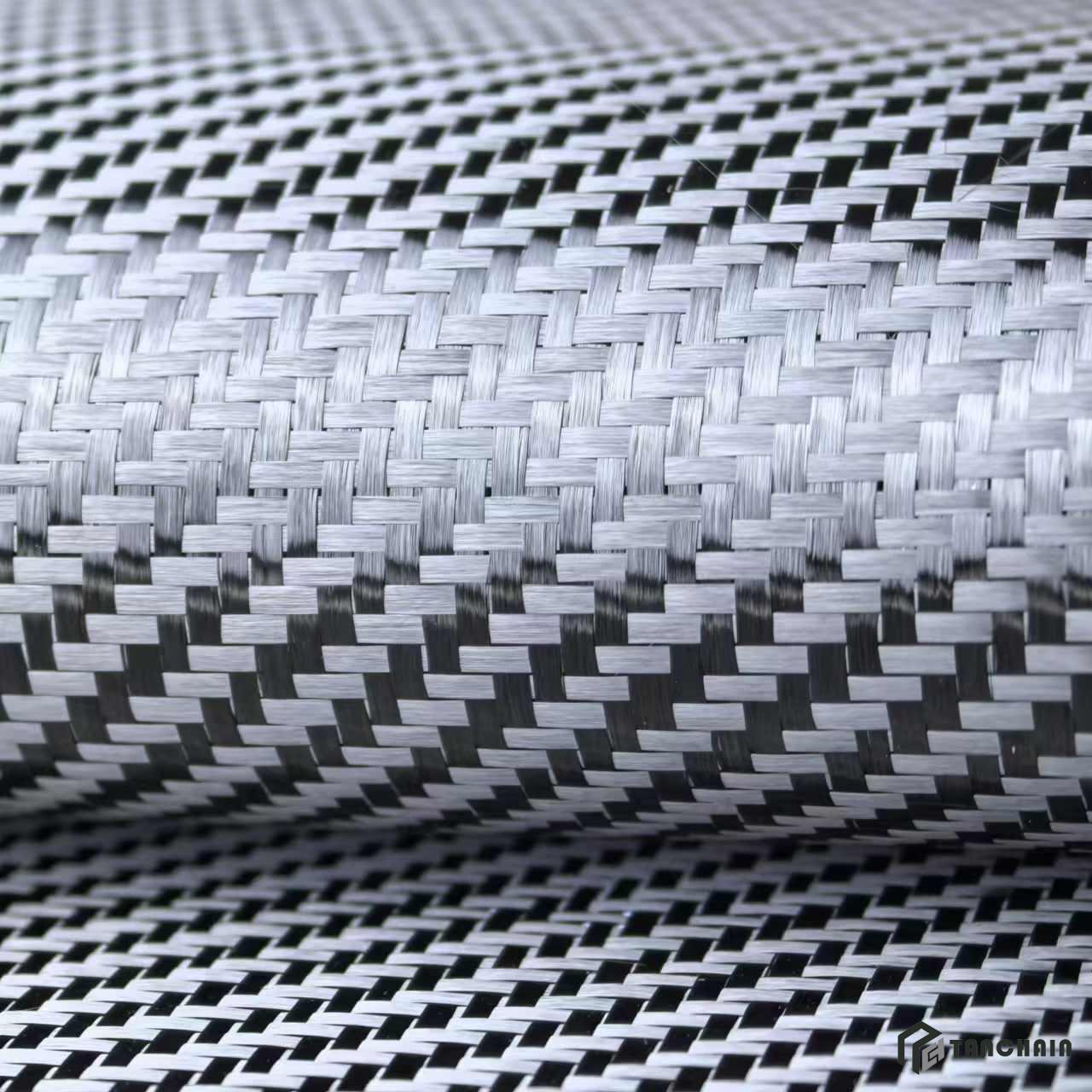

1K - 100gsm - Twill Carbon Fabric - 3oz

- Code:TC-CF-1KC100T

- Material:100% Carbon Fabric

- Weight:100GSM

- Function:Aerospace, electronic device, Luxury, micro drones.

- Color:Black

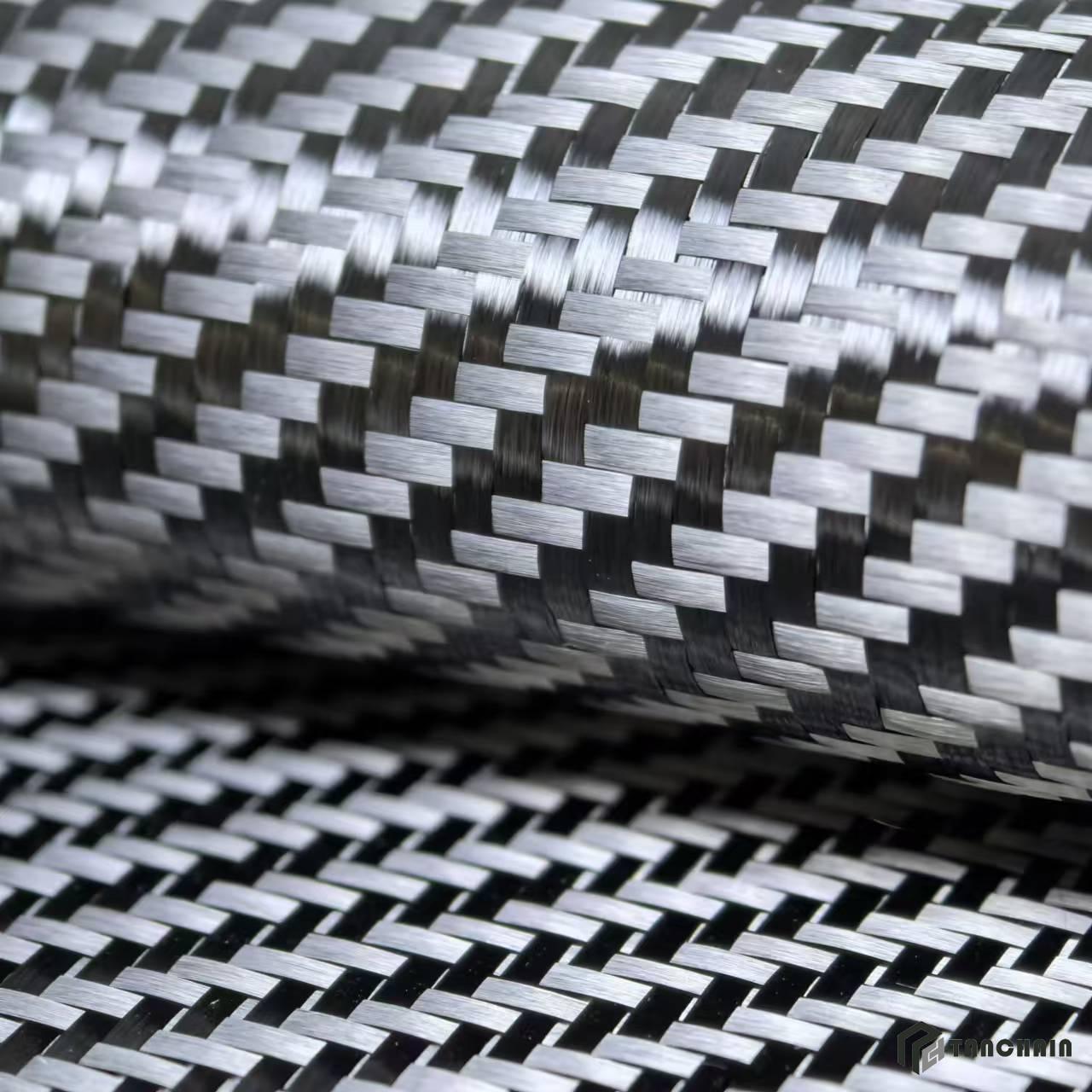

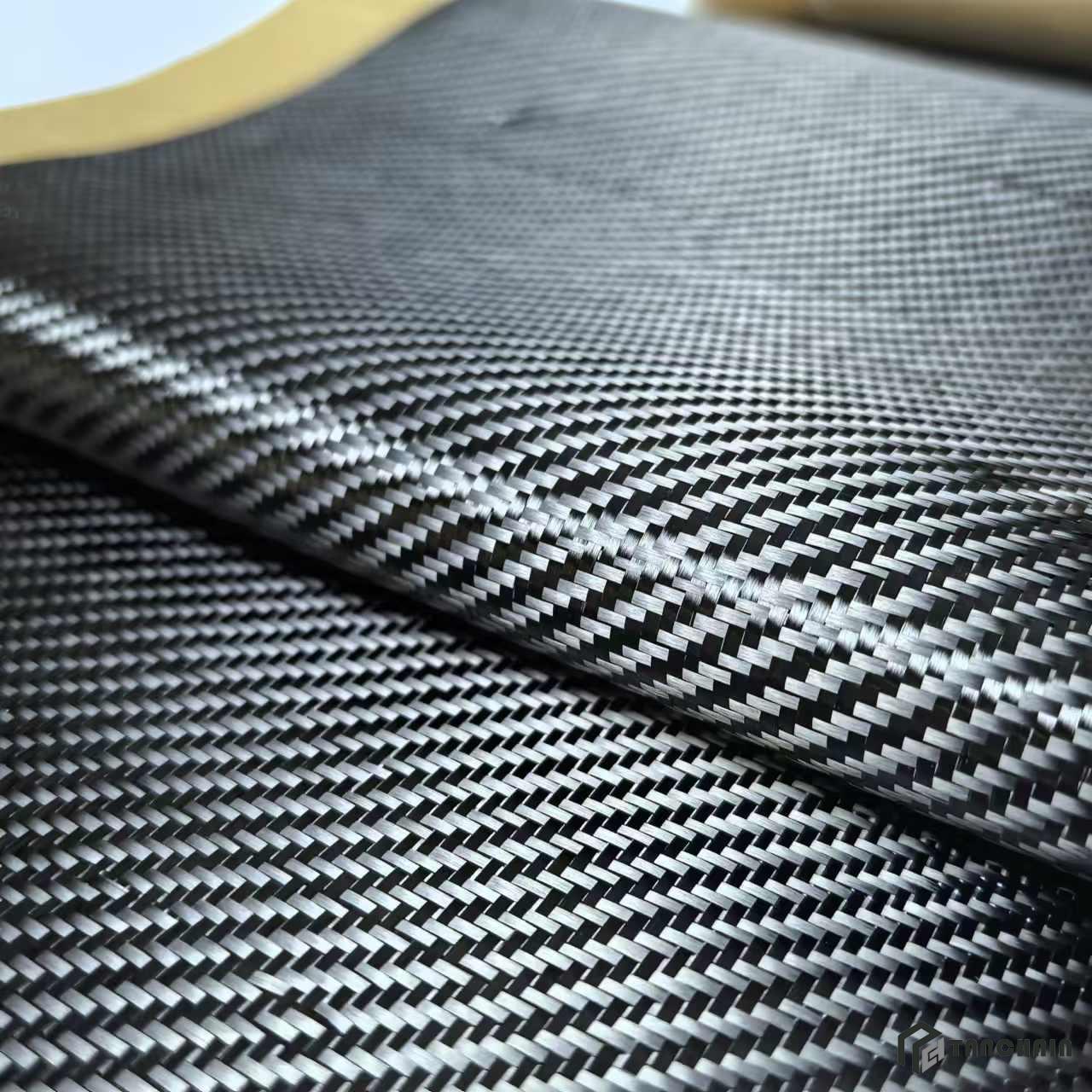

- Weave:Twill

- Width:100cm

SEND INQUIRY

Material: |

100% carbon fiber | Yarn (warp): | 1k carbon fiber |

| Pattern: | Twill | Yarn (weft): | 1k carbon fiber |

| Weight : | 100gsm | Width: | 10-150cm |

| Density(warp): | 7.5/10mm | Thickness: | 0.15mm |

| Warp tensile strength | >300N/25mm | Weft tensile strength | >240N/25mm |

| Density(weft): | 7.5/10mm | Color: | Black |

Material: |

100% carbon fiber |

| Pattern: | Twill |

| Weight : | 100gsm |

| Density(warp): | 7.5/10mm |

| Density(weft): | 7.5/10mm |

| Yarn Count(warp): | 1k carbon fiber |

| Yarn Count(weft): | 1k carbon fiber |

| Width: | 10-150cm |

| Warp tensile strength | >300N/25mm |

| Weft tensile strength | >240N/25mm |

| Thickness: | 0.15mm |

| Color | Black |

Product Description

The "K" of carbon fiber fabric stands for the number of carbon fiber tows, and 1K means there are 1,000 filaments in a bundle of carbon fiber. 120 grams and 80 grams refer to the weight of carbon fiber fabric per square meter.

120 grams 1K carbon fiber fabric

- Advantages

- High strength: Because it is heavier and has a higher carbon fiber content, it can withstand greater external forces such as tension and has a good reinforcement effect.

- Thickness is relatively large: It is more suitable in scenarios where a certain thickness needs to be increased to meet specific requirements.

- Disadvantages

- Slightly less flexible: Compared with 80 grams, it has a harder texture and is limited in some application scenarios that require bending and fitting complex shapes.

- Higher cost: Due to the high carbon fiber content, the price is generally more expensive.

- Application scenarios

- Exquisite electronic products: It can reduce the weight of electronic products, improve strength, and beautify the static view.

- Repair of industrial equipment with extremely high strength requirements: such as key load-bearing parts of large machinery.

80g 1K carbon fiber fabric

- Advantages

- Good flexibility: It can be well attached to the surface of objects with various complex shapes, which is convenient for construction operations.

- Low cost: The price is relatively cheap and economical.

- Disadvantages

- Relatively weak strength: For some scenes with high strength requirements, it may not meet the needs.

- Limited protection ability: If used in places with high protection requirements, the thinner thickness will make its protection performance insufficient.

- Application scenarios

- Appearance repair: For example, repairing the surface of automobiles, sports equipment, etc., restoring the appearance while increasing a certain strength.

- Reinforcement of products with complex shapes and not particularly high strength requirements: such as some artistic carbon fiber products.

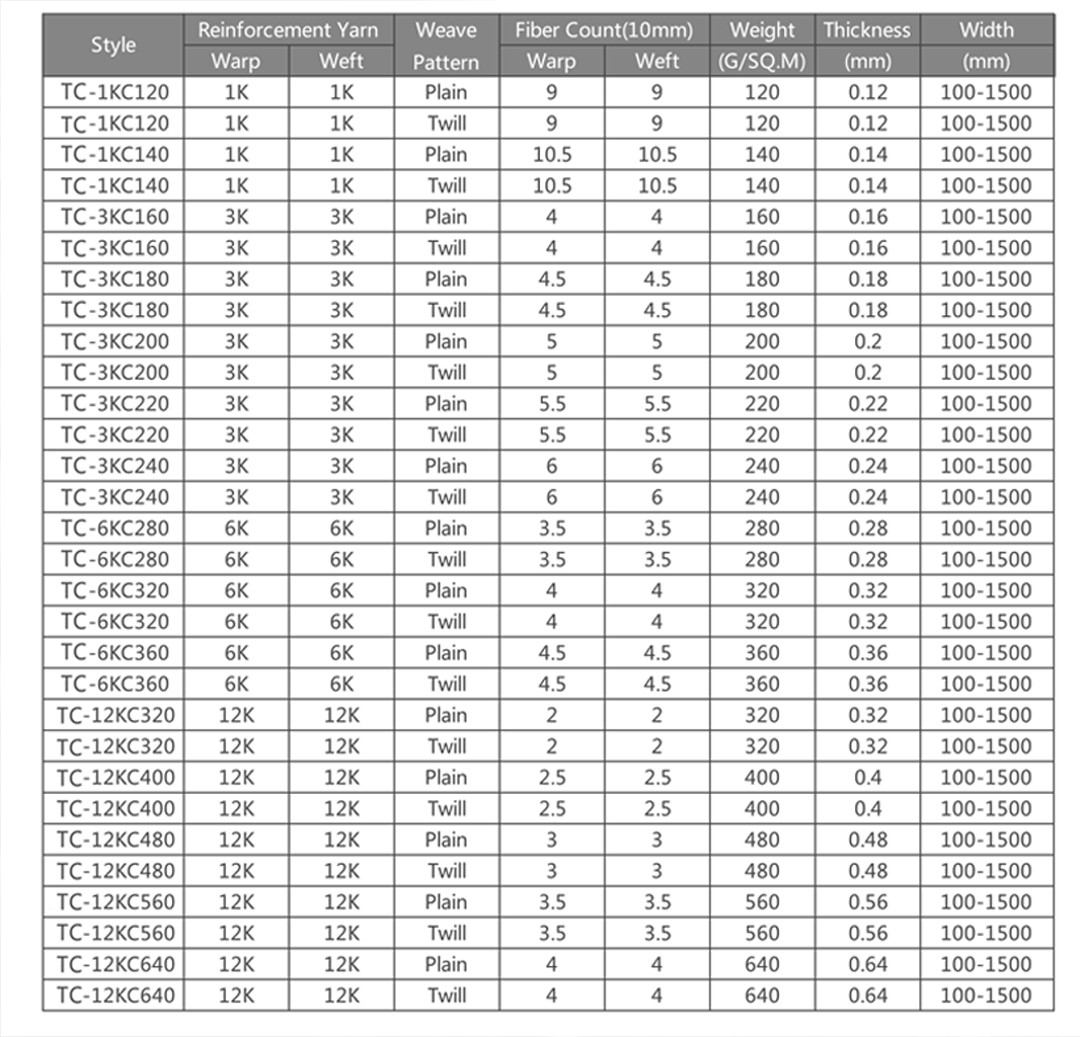

Similar Series Technical Data