-

-

3K - Carbon fiber filaments

- Code:TC-CF-3K

- Material:100% Carbon Fiber

- Weight:3k filaments

- Function:High strength, Low weight.

- Color:Black

SEND INQUIRY

Characteristics of 3K carbon fiber filament:

1. Physical properties:

- High strength: It has high tensile strength and can withstand large tension and stress. Its strength is significantly better than many traditional materials, such as steel. This makes 3K carbon fiber filament have great application advantages in structural parts that need to withstand high stress.

- High modulus: The modulus reflects the ability of the material to resist deformation. The high modulus of 3K carbon fiber filament makes it deform very little when subjected to force. It has excellent rigidity and dimensional stability and is suitable for application scenarios with high dimensional accuracy requirements.

- Lightweight: Carbon fiber materials have low density, and 3K carbon fiber filament is no exception. The light weight feature is very important for some application fields with strict weight restrictions, such as the aerospace field, which can reduce the weight of the aircraft, reduce energy consumption, and improve flight performance.

- Low thermal expansion coefficient: When the temperature changes, 3K carbon fiber filament has good dimensional stability, is not easy to produce obvious expansion or contraction due to temperature changes, and can maintain stable performance under different temperature environments.

- Good wear resistance: The surface of carbon fiber filament is relatively smooth, but it also has high wear resistance, is not easy to wear and damage, and can maintain good performance in long-term use.

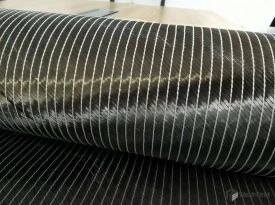

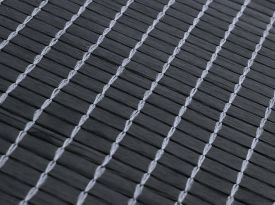

2. Appearance characteristics:

- Fine texture: Compared with large-tow carbon fiber, the cloth woven from 3K carbon fiber filament is finer, smoother, and has a good texture. It has a high aesthetics and is suitable for products with high appearance requirements.

3. Chemical properties:

- Corrosion resistance: It has good corrosion resistance and has strong resistance to chemical substances such as acids, alkalis, and organic solvents. It can maintain stable performance in harsh chemical environments.

- Good conductivity: Carbon fiber is a good conductive material. 3K carbon fiber filament can be used in occasions that require conductive properties, such as electronic equipment, electromagnetic shielding, etc.

Main uses of 3K carbon fiber filament:

1. Aerospace field:

Aircraft, spacecraft, etc. have extremely high requirements on the performance of materials. The high strength, light weight, and high temperature resistance of 3K carbon fiber filament make it possible to manufacture aircraft wings, fuselage structural parts, satellite structural parts, etc.

2. Sports goods:

Sports equipment needs to be lightweight and high-strength. 3K carbon fiber filaments can be used to manufacture high-end sports equipment such as golf clubs, tennis rackets, bicycle racks, and skis.

3. Automobile:

It can be used for automobile modification and the manufacture of high-performance components, such as the body shell, hood, spoiler, etc. of the car, which can improve the strength and rigidity of the car, while reducing the weight of the car body and improving the performance of the car.

4. Construction:

It has important applications in the reinforcement and repair of building structures. It can be used to reinforce concrete structures, bridges, piers and other building components to improve their bearing capacity and seismic resistance.

5. Electronic equipment:

Due to its good electrical conductivity and electromagnetic shielding properties, it can be used to manufacture electronic equipment housings, radiators, circuit boards and other components, which can protect electronic equipment from electromagnetic interference.

6. Industrial:

It can be used to manufacture mechanical parts, molds, etc. It has the advantages of high strength, high rigidity, and wear resistance, which can improve the performance and service life of industrial equipment.

Disadvantages of 3K carbon fiber filament:

1. High cost:

The process of producing 3K carbon fiber filament is complicated, the cost of carbonization equipment is high, and the control requirements of the production process are strict, resulting in high production costs, so the price of the product is relatively expensive, which to a certain extent limits its large-scale application.

2. Difficult processing:

Carbon fiber filament has high hardness and certain brittleness. Special processing equipment and processes are required during the processing process. The requirements for processing technology are high and the processing difficulty is relatively high. For example, during cutting, drilling and other processing operations, fiber breakage and delamination are prone to occur.

3. Poor impact resistance:

Although 3K carbon fiber filament has high strength, its impact resistance is relatively poor, and it is easy to break or damage when subjected to a large impact force.

4. Compatibility issues with other materials:

There is a certain difficulty in connecting and combining carbon fiber with some metal materials or other non-metallic materials. Special connection methods and processes are required, otherwise problems such as loose connection and poor interface bonding are prone to occur.

5. Difficulty in recycling:

It is difficult to recycle and reuse carbon fiber filaments. The current recycling technology is not mature enough and the recycling cost is high, which also increases its use cost and environmental burden to a certain extent.

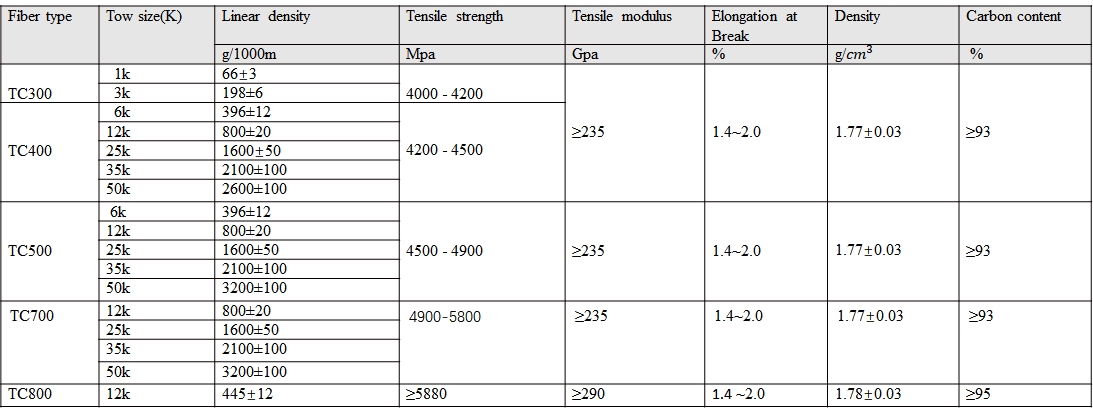

Technical Data

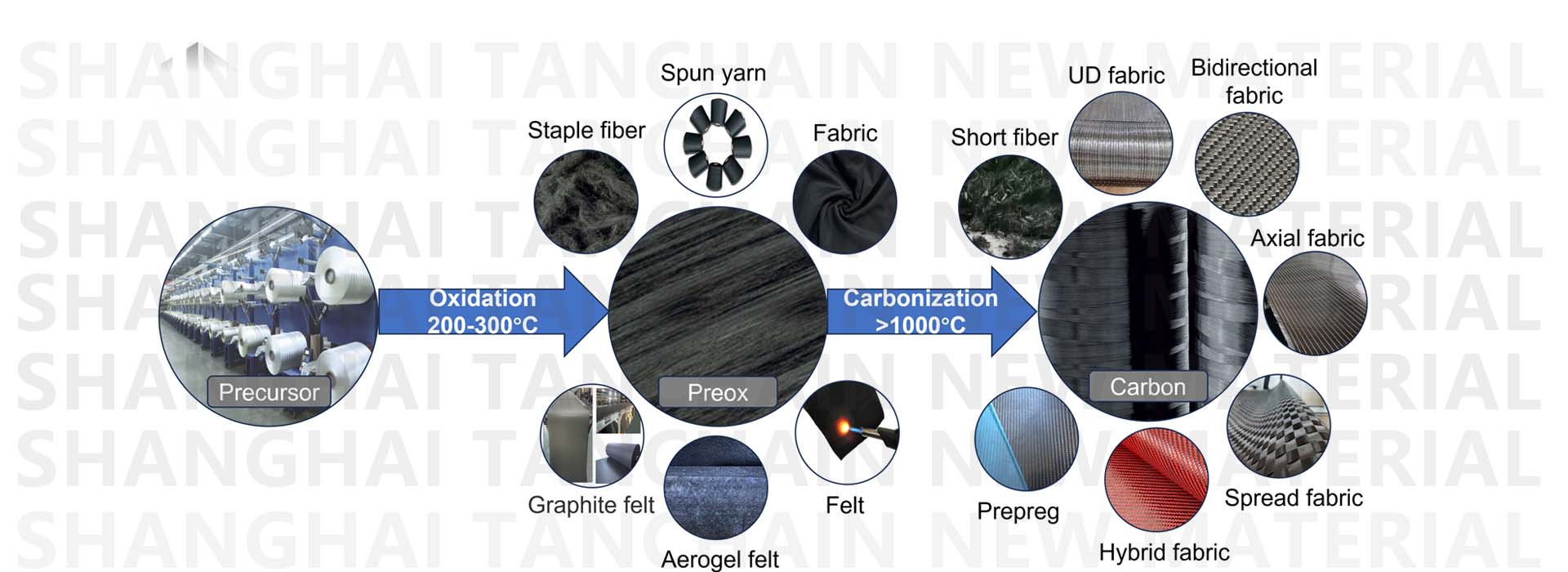

Production Line

Tanchain's Production Flow

SHIPPING