-

-

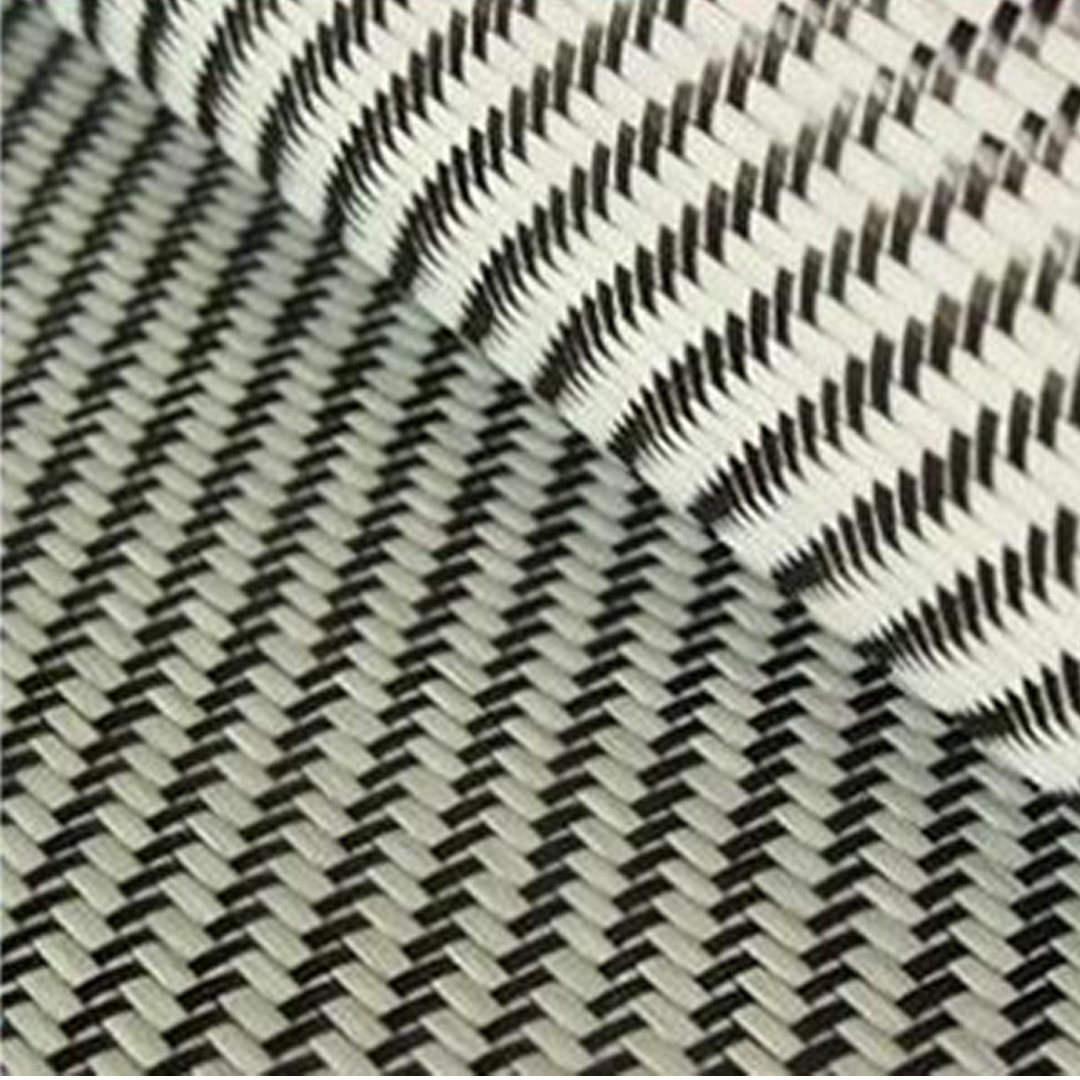

3K Twill - Carbon Fabric - Kevlar fabric - Para aramid Fabric

- Code:TC-CKR-C200T

- Material:50% Carbon fiber, 50% Kevlar

- Weight:200gsm

- Function:High Temperature Resistant, High Strength, Flame Retardant, Fire Retardant, Waterproof, Anti-Static

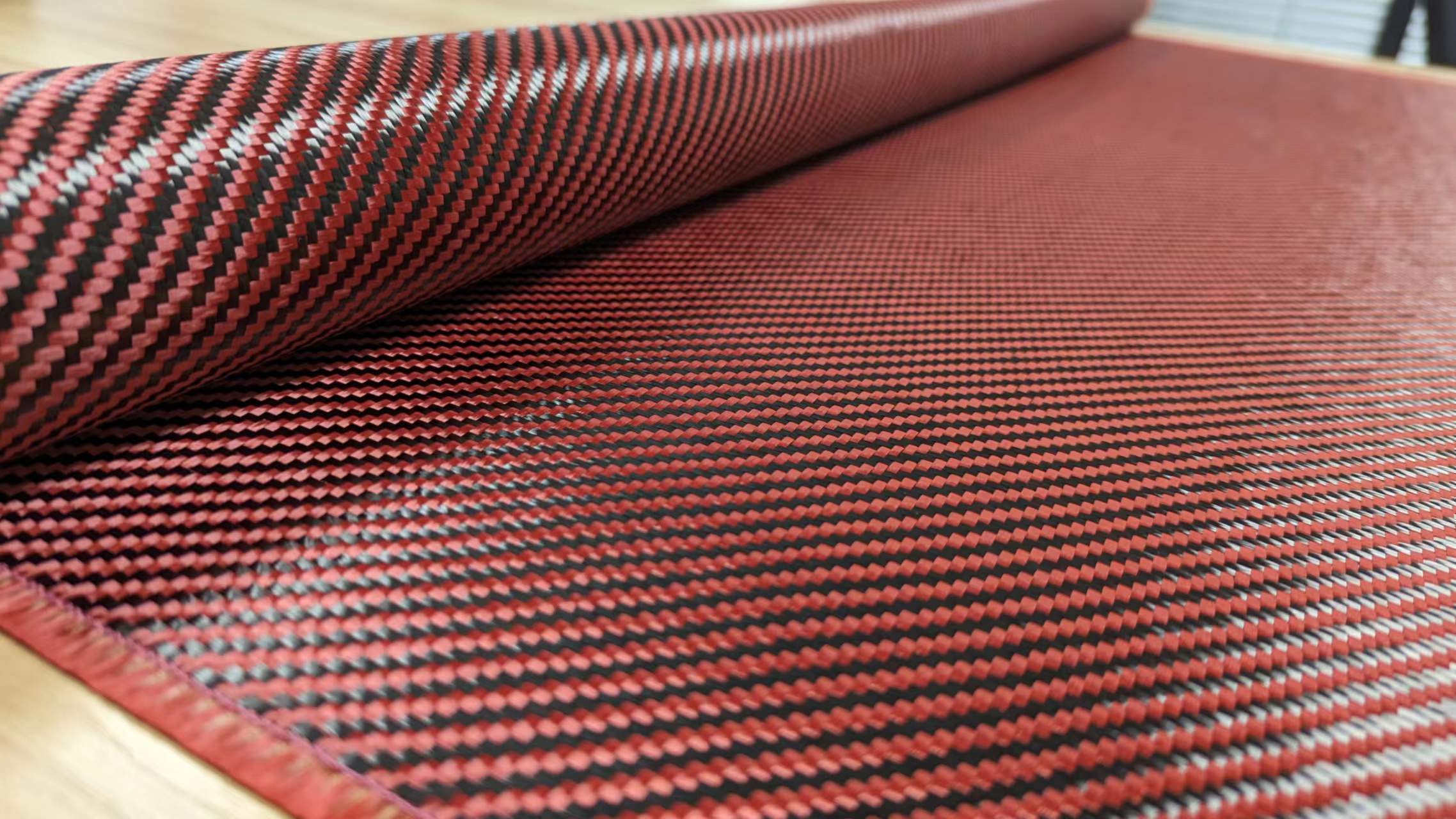

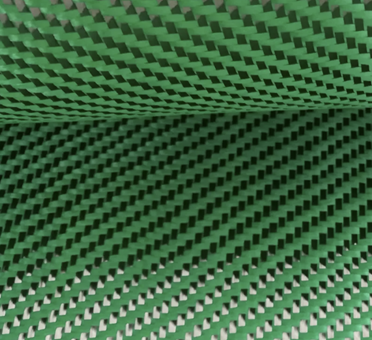

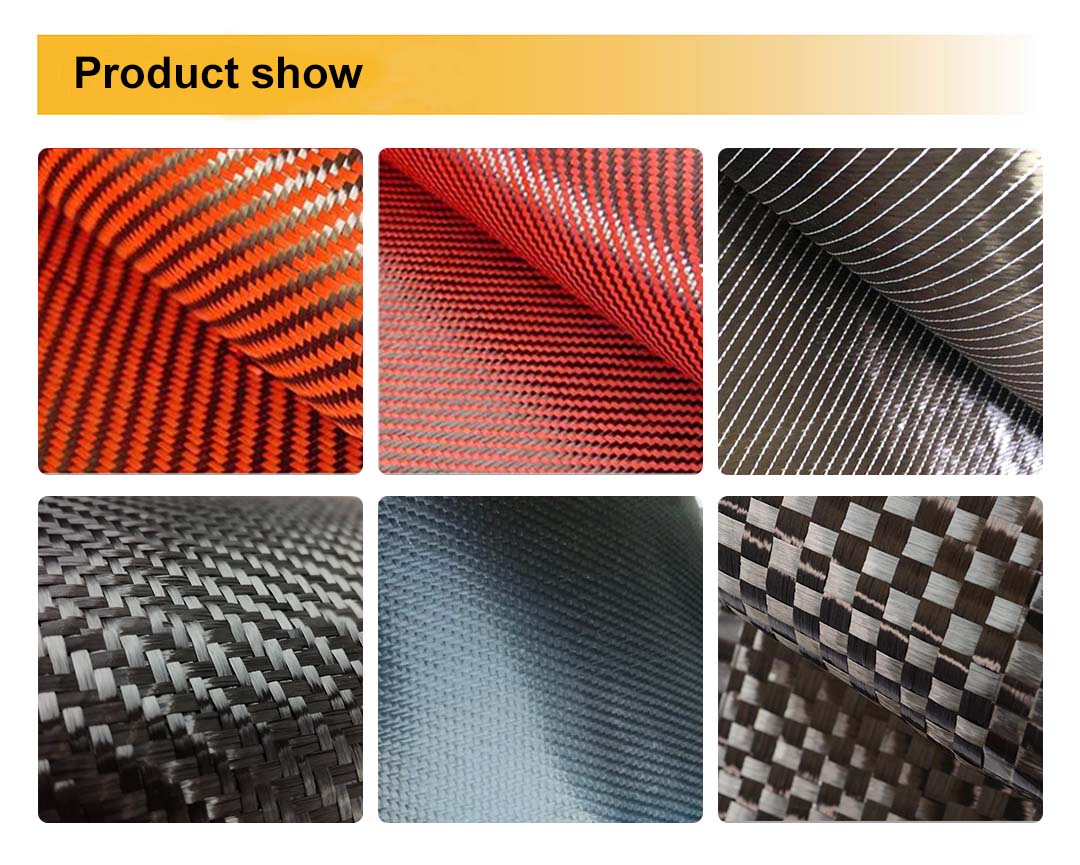

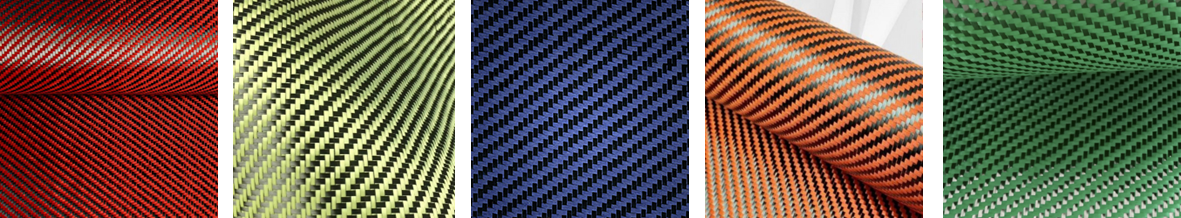

- Color:Black and Yellow, Red, Blue, Orange interweaving

- Weave:Twill

- Width yarn:10~150CM

SEND INQUIRY

Product Properties

Carbon and Kevlar hybrid fabric combines the benefits of these two amazing materials to create one super material.

The carbon fiber provides high strength and stiffness while the aramid Kevlar is good at impact, fracture, abrasion resistance.

The coloring of the Kevlar fabric also adds a unique aesthetic to carbon product.

Material: |

50% para aramid, kevlar, 50% carbon fiber | Yarn Count(warp): | 3k carbon fiber |

| Pattern: | Plain | Yarn Count(weft): | 1500D kevlar |

| Weight : | 210gsm | Width: | 10-150cm |

| Density(warp): | 5.5/10cm | Thickness: | 0.25mm |

| Density(weft): | 5.5/10cm | Color: | Black and Yellow, Red, Blue, Orange interweaving |

Material: |

50% para aramid, kevlar, 50% carbon fiber |

| Pattern: | Plain |

| Weight : | 210gsm |

| Density(warp): | 5.5/10cm |

| Density(weft): | 5.5/10cm |

| Yarn Count(warp): | 3k carbon fiber |

| Yarn Count(weft): | 1500D kevlar |

| Width: | 10-150cm |

| Thickness: | 0.25mm |

| Color | Black and Yellow, Red, Blue, Orange interweaving |

Product Description

Hybrid Fabrics are made from more than two different fiber materials (carbon fiber, aramid fiber, basalt fiber, glass fiber and other composite materials) from the composite, which has a composite of high impact strength, rigidity and tensile strength performance. The main role of mixed cloth is to increase the vibration strength of civil buildings, bridges and tunnels, reinforced concrete structures and strong materials.

Hybird fabrics has a wide range of applications such as automotive engineering, motorcycle, fashion decoration, aircraft manufacturing, ship building, sports equipment, electronic products.

Similar Series Technical Data

APPLICATIONS

SHIPPING

Q1:Are you a factory? Where are you located?

A: We are a professional manufacturer with more than 5 years production experience of composite materials, We have two factories, one in Nantong, Jiangsu, China and the other in Bangkok, Thailand.

Q2:What's the MOQ?

A: Usually 100SQM.

Q3:Package & Shipping.

A: Normal package: by carton.

Q4:When can we offer?

A: We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price pls call us or send email to us, so that we can reply you with priority.

Q5:How do you charge the sample fees?

A: If you need a samples from our stock, we can provide to you for free, but the free charge should be on your side. If you need a special size, We will charge the sample making fee which will be refund when you place an order.

Q6:What's your delivery time for production?

A:If we have stock , can delivery in 1-7 days, if without stock, need 5-30 days, depend on quantity.

Q7:What is your payment term?

A: Paypal, T/T, L/C AT sight, D/P and Western Union