-

Potential New Materials In The Future

-

According to the research progress of well-known research institutions and companies at home and abroad, 20 new materials were selected.

The material industry is the basic industry of the national economy, and new materials are the forerunner of the development of the material industry. Graphene, carbon nanotubes, amorphous alloys, metal foams, ionic liquids... 20 new materials bring unlimited opportunities for the development of the materials industry.

Today, the scientific and technological revolution is developing rapidly, new materials and products are changing with each passing day, and the pace of industrial upgrading and material replacement is accelerating. The integration of new material technology with nanotechnology, biotechnology and information technology, the integration of structure and function, and the intelligent trend of functional materials are obvious.

In this paper, 20 new materials are selected based on the research progress of well-known research institutions and companies at home and abroad, scientific and technological media reviews, and industry hot research. The following is the detailed information of the relevant materials (in no particular order).

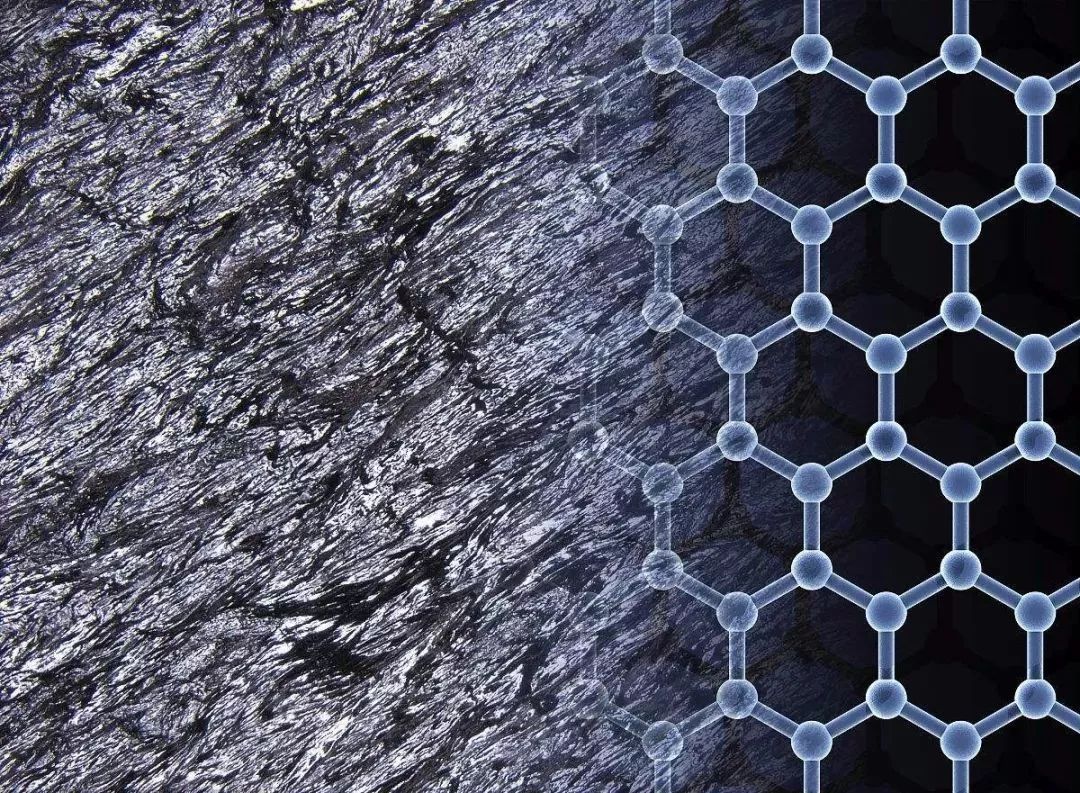

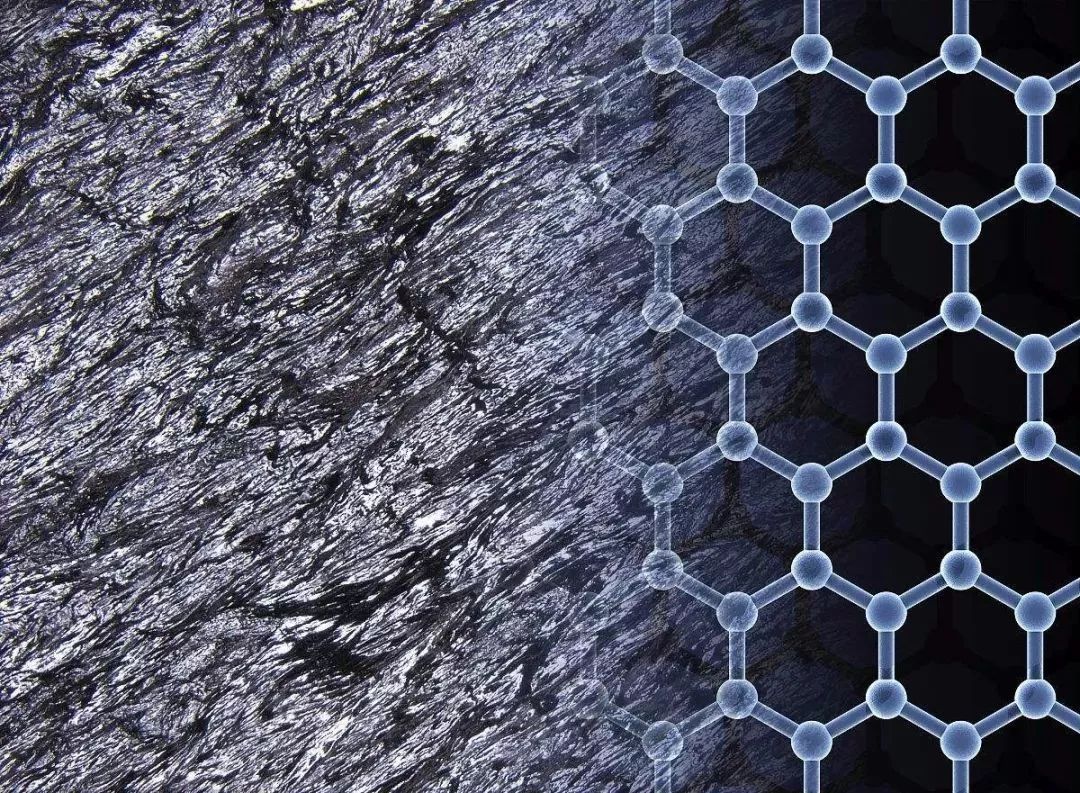

1.Graphene

Breakthrough: Extraordinary electrical conductivity, extremely low resistivity and extremely fast electron migration, dozens of times stronger than steel and excellent light transmittance.

Development trend: The 2010 Nobel Prize in Physics has made graphene very popular in technology and capital markets in recent years. In the next five years, graphene will be used in optoelectronic displays, semiconductors, touch screens, electronic devices, energy storage batteries, displays, sensors, semiconductors, aerospace, military, composite Materials, biomedicine and other fields will experience explosive growth.

Main research institutions (companies): Graphene Technologies, Angstron Materials, Graphene Square, Forsman Technology, etc.

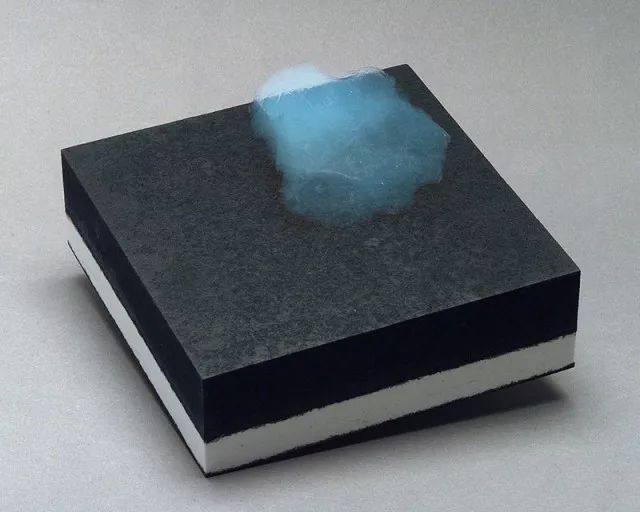

2. Aerogels

Breakthrough: high porosity, low density and light weight, low thermal conductivity, excellent thermal insulation properties. Development trend: New materials with great potential have great potential in the fields of energy conservation and environmental protection, thermal insulation, electronic appliances, and construction.

Main research institutions (companies): Forsman Technology, W.R. Grace, Japan Fuji-Silysia Company, etc.

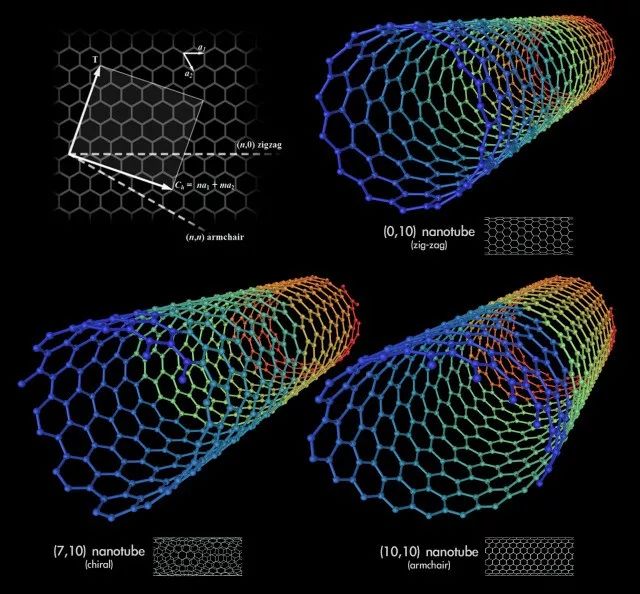

3. Carbon Nanotubes

Breakthrough: high electrical conductivity, high thermal conductivity, high elastic modulus, high tensile strength, etc.

Development trend: electrodes for functional devices, catalyst carriers, sensors, etc.

Main research institutions (companies): Unidym, Inc., Toray Industries, Inc., Bayer Materials Science AG, Mitsubishi Rayon Co., Ltd. Forsman Technology, Suzhou First Element, etc.

4. Fullerenes

Breakthrough: with linear and nonlinear optical properties, alkali metal fullerene superconductivity, etc.

Development trend: In the future, it will have important prospects in the fields of life science, medicine, astrophysics, etc. It is expected to be used in optoelectronic devices such as optical converters, signal conversion and data storage.

Main research institutions (companies): Michigan State University, Xiamen Funa New Materials, etc.

5. Amorphous Alloys

Breakthrough: high strength and toughness, excellent magnetic permeability and low magnetic loss, excellent liquid fluidity.

Development trend: in high-frequency low-loss transformers, structural parts of mobile terminal equipment, etc.

Main research institutions (companies): Liquidmetal Technologies, Inc., Institute of Metals, Chinese Academy of Sciences, BYD Co., Ltd., etc.

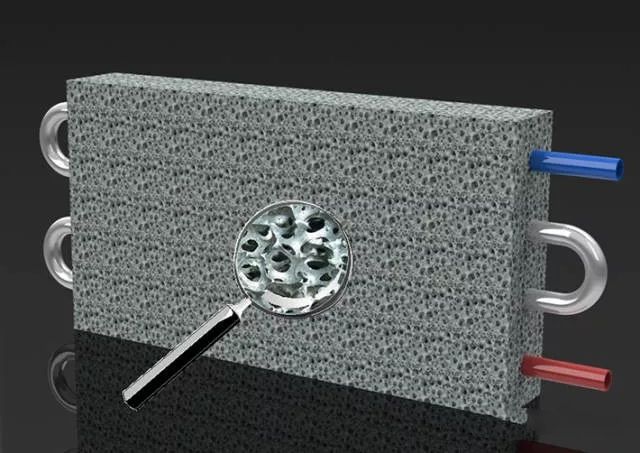

6. Foam Metal

Breakthrough: Light weight, low density, high porosity, and large surface area.

Development trend: It has electrical conductivity and can replace the application fields where inorganic non-metallic materials cannot conduct electricity; it has great potential in the field of sound insulation and noise reduction.

Main research institutes (companies): Alcan (Alcoa), Rio Tinto, Symat, Norsk Hydro, etc.

7. Ionic Liquids

Breakthrough: It has high thermal stability, wide liquid temperature range, adjustable acidity and alkalinity, polarity, coordination ability, etc.

Development trend: It has broad application prospects in the field of green chemical industry, as well as in the fields of biology and catalysis.

Main research institutions (companies): Solvent Innovation, BASF, Lanzhou Institute of Physics, Chinese Academy of Sciences, Tongji University, etc.

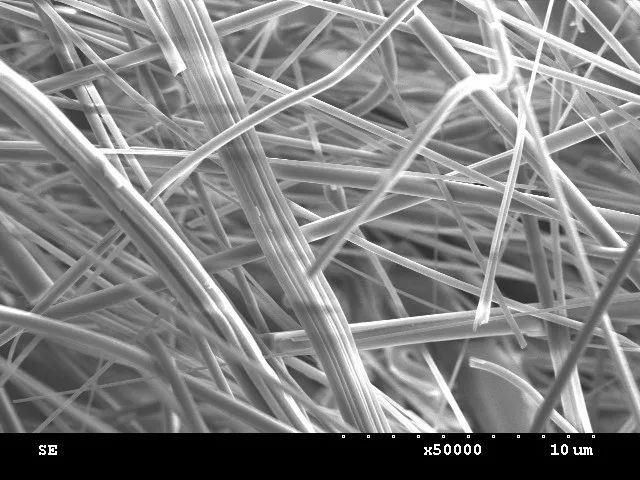

8. Nanocellulose

Breakthrough: good biocompatibility, water holding capacity, wide range of pH stability; nano-network structure, and high mechanical properties, etc.

Development trend: It has great prospects in biomedicine, enhancer, paper industry, purification, conductive and inorganic compound food, and industrial magnetic compound.

Main research institutions (companies): Cellu Force (Canada), US Forest Service (US Forest Service), Innventia (Sweden), etc

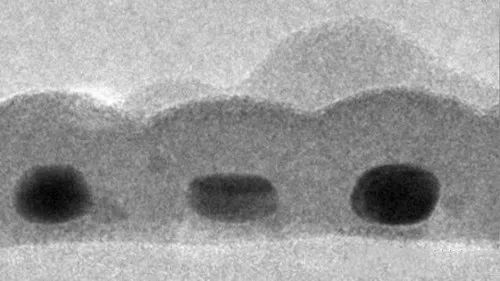

9. Nanodot perovskites

Breakthrough: Nanodot perovskites have giant magnetoresistance, high ionic conductivity, catalysis for oxygen evolution and reduction, etc.

Development trend: In the future, it has great potential in the fields of catalysis, storage, sensors, and light absorption.

Main research institutions (companies): Apry, AlfaAesar, etc.

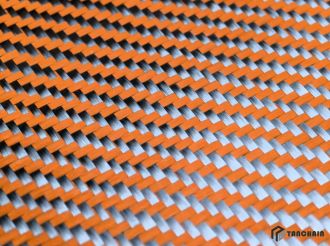

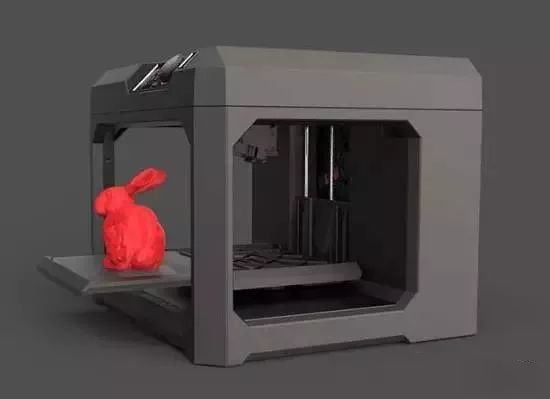

10. 3D Printing Materials

Breakthrough: Change the processing methods of traditional industries, and can quickly realize the forming of complex structures, etc.

Development trend: Revolutionary molding method has great prospects in the field of complex structure molding and rapid processing molding.

Main research institutions (companies): Object, 3DSystems, Stratasys, Farsoon, etc.

11. Flexible Glass

Breakthrough: Change the rigid and fragile characteristics of traditional glass, and realize the revolutionary innovation of glass flexibility.

Development trend: In the future, the field of flexible display and foldable devices has great prospects.

Main research institutions (companies): Corning Corporation, Schott Group, etc.

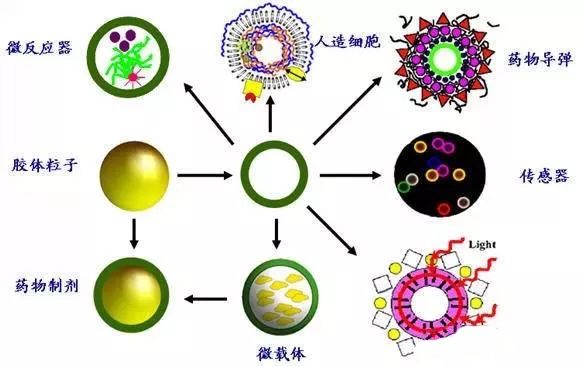

12. Self-assembling (self-healing) materials

Breakthrough: self-assembly of material molecules, realizing the "intelligence" of the material itself, changing the previous material preparation method, and realizing the spontaneous formation of a certain shape and structure of the material itself.

Development trend: Change the traditional material preparation and material repair methods, and have great prospects in the fields of molecular devices, surface engineering, and nanotechnology in the future.

Main research institutions (companies): Harvard University, etc.

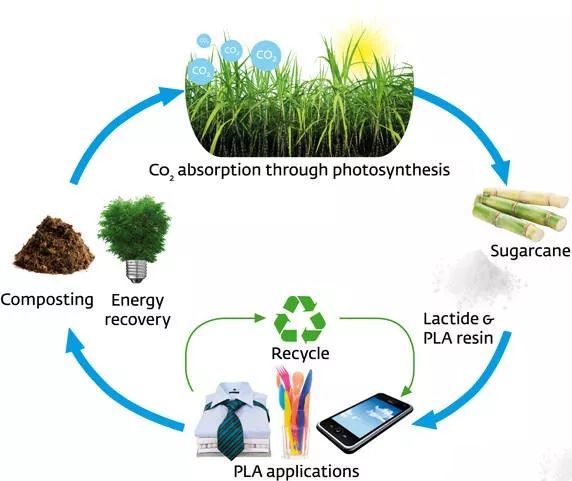

13. Degradable Bioplastics

Breakthrough: It can be naturally degraded, and the raw materials come from renewable resources, changing the dependence of traditional plastics on fossil resources such as oil, natural gas, and coal, and reducing environmental pollution.

Development trend: the future replacement of traditional plastics has great prospects.

Main research institutions (companies): Natureworks, Basf, Kaneka, etc.

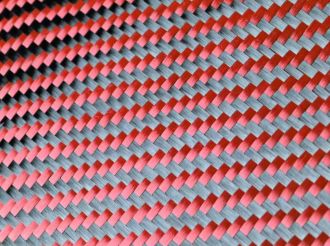

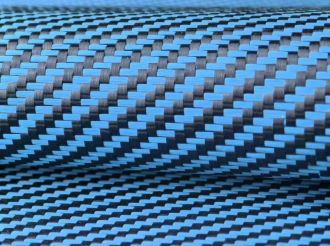

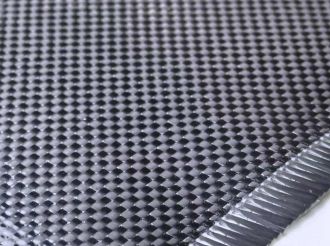

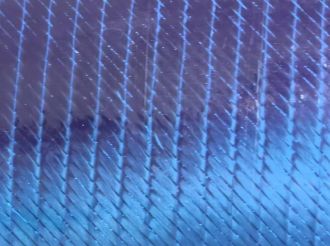

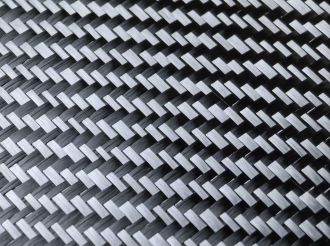

14. Titanium Carbon Composites

Breakthrough: With high strength, low density, and excellent corrosion resistance, it has unlimited prospects in the aviation and civil fields.

Development trend: In the future, it has a wide range of potential applications in lightweight, high-strength, corrosion-resistant and other environments.

Main research institutions (company): Harbin Institute of Technology, etc.

15. Metamaterials

Breakthrough: It has physical properties that conventional materials do not have, such as negative permeability, negative permittivity, etc.

Development trend: change the traditional concept of processing according to the properties of materials, and design the characteristics of materials according to needs in the future, with unlimited potential and revolutionary.

Main research institutions (companies): Boeing, Kymeta, Shenzhen Guangqi Research Institute, etc.

16. Superconducting Materials

Breakthrough: In the superconducting state, the material has zero resistance, no current loss, and the material exhibits diamagnetism in a magnetic field.

Development trend: In the future, if breakthroughs in high-temperature superconducting technology are expected, it is expected to solve problems such as power transmission loss, heating of electronic devices, and green new transmission magnetic suspension technology.

Main research institutions (companies): Sumitomo Japan, Bruker Germany, Chinese Academy of Sciences, etc.

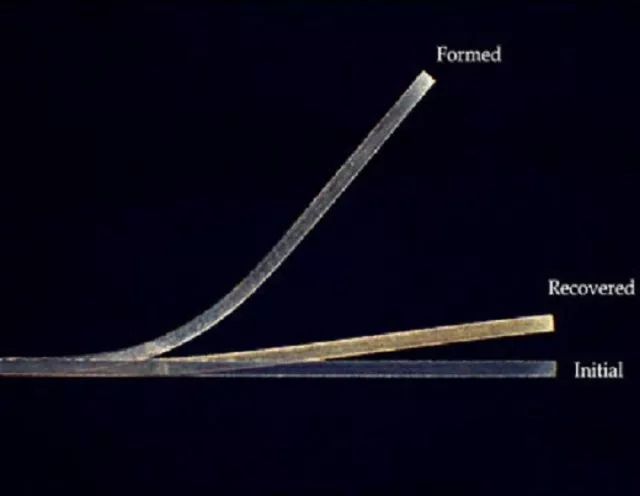

17. Shape Memory Alloys

Breakthrough: After pre-forming, after being forced to deform by external conditions, it can be restored to its original shape after certain conditions, so as to realize the design and application of the material's deformation reversibility.

Development trend: huge potential in space technology, medical equipment, mechanical and electronic equipment and other fields.

Main research institutions (companies): There are new materials and so on.

18. Magnetostrictive Materials

Breakthrough: Under the action of a magnetic field, it can produce the properties of elongation or compression, and realize the interaction of material deformation and magnetic field.

Development trend: It is widely used in the fields of intelligent structural devices, shock absorption devices, transducer structures, high-precision motors, etc., and its performance is better than piezoelectric ceramics under some conditions.

Main research institutions (companies): American ETREMA Company, British Rare Earth Products Company, Japan Sumitomo Light Metal Company, etc.

19. Magnetic (Electro) Fluid Materials

Breakthrough: In liquid state, it has both the magnetic properties of solid magnetic materials and the fluidity of liquids, and has characteristics and applications that traditional magnetic bulk materials do not have.

Development trend: used in magnetic sealing, magnetic refrigeration, magnetic heat pump and other fields, changing the traditional sealing refrigeration and other methods.

Main research institutions (companies): ATA Applied Technology Corporation of the United States, Panasonic of Japan, etc.

20. Smart Polymer Gels

Breakthrough: It can perceive changes in the surrounding environment and respond, with biological-like response characteristics.

Development trend: The expansion-contraction cycle of smart polymer gels can be used for chemical valves, adsorption separation, sensors and memory materials; the power provided by the cycle is used to design "chemical engines"; the controllability of mesh is suitable for smart drug release systems Wait.

Main research institutions (companies): American and Japanese universities.