-

-

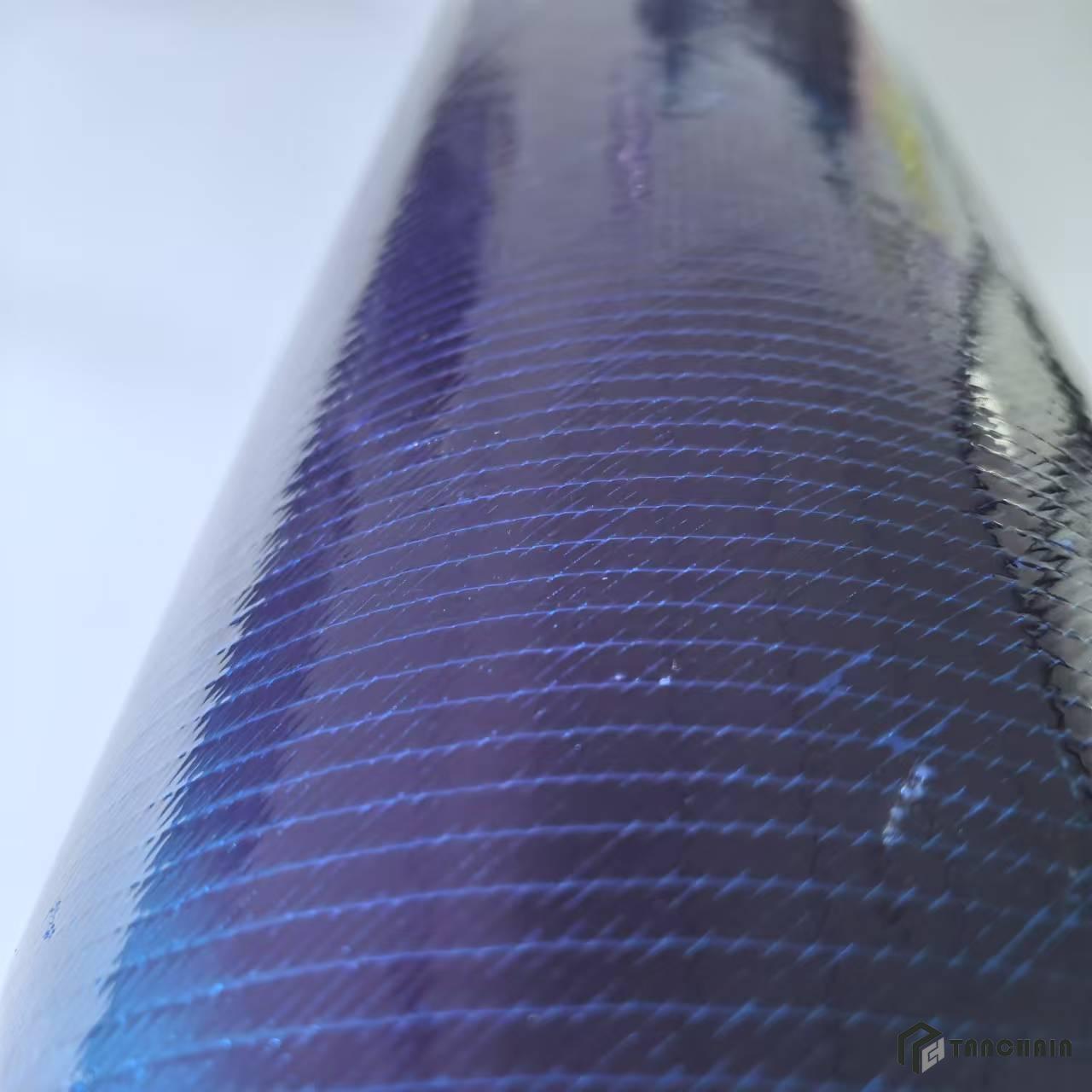

330gsm - Biaxial ±45° Carbon Fiber Prepreg -12K T400

- Code:TC-CFP-X200B

- Material:60% Carbon Fiber Fabric, 40% resin

- Weight:330gsm

- Function:High strengh, Low weight, Good looking, High modulus, Low thermal expansion

- Color:Black

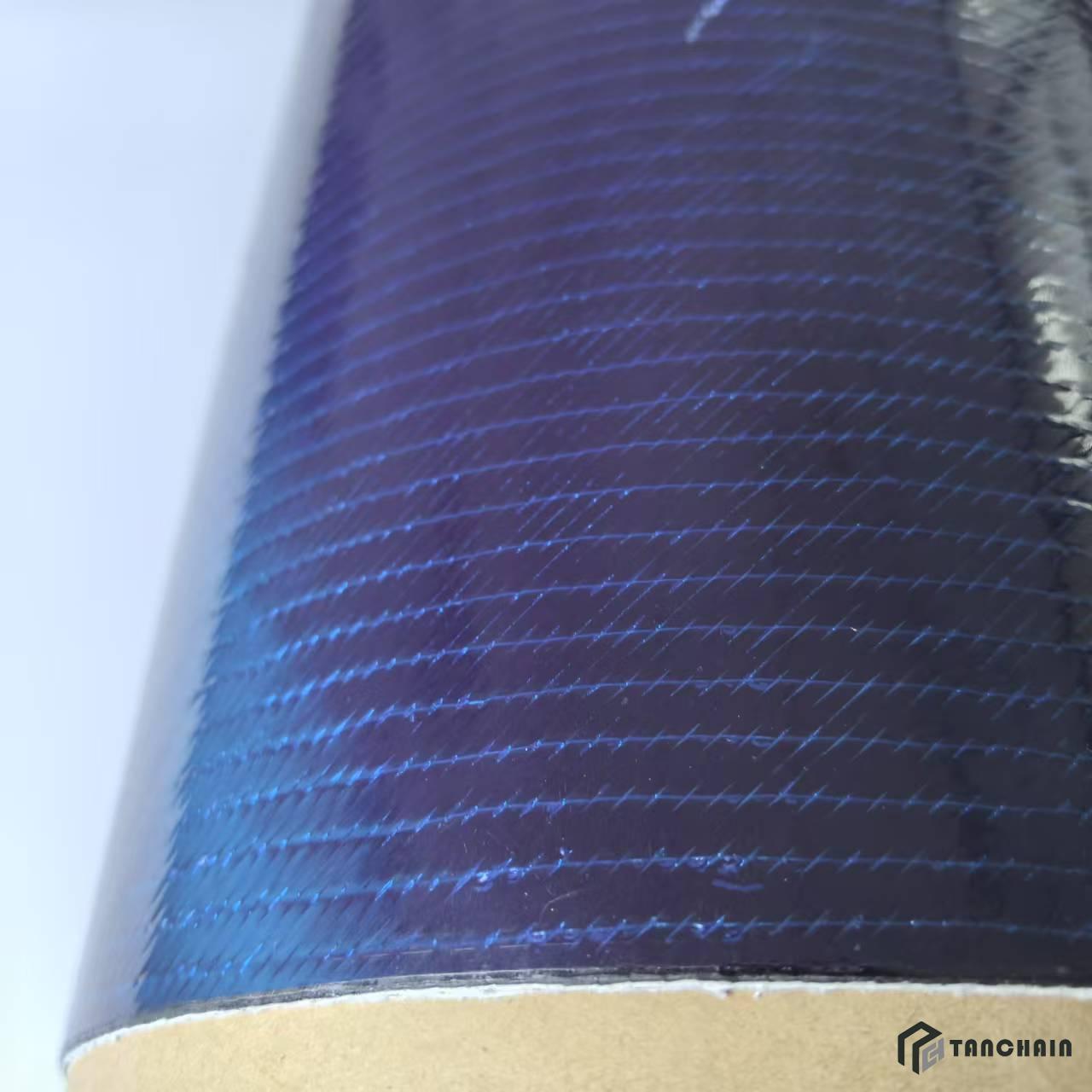

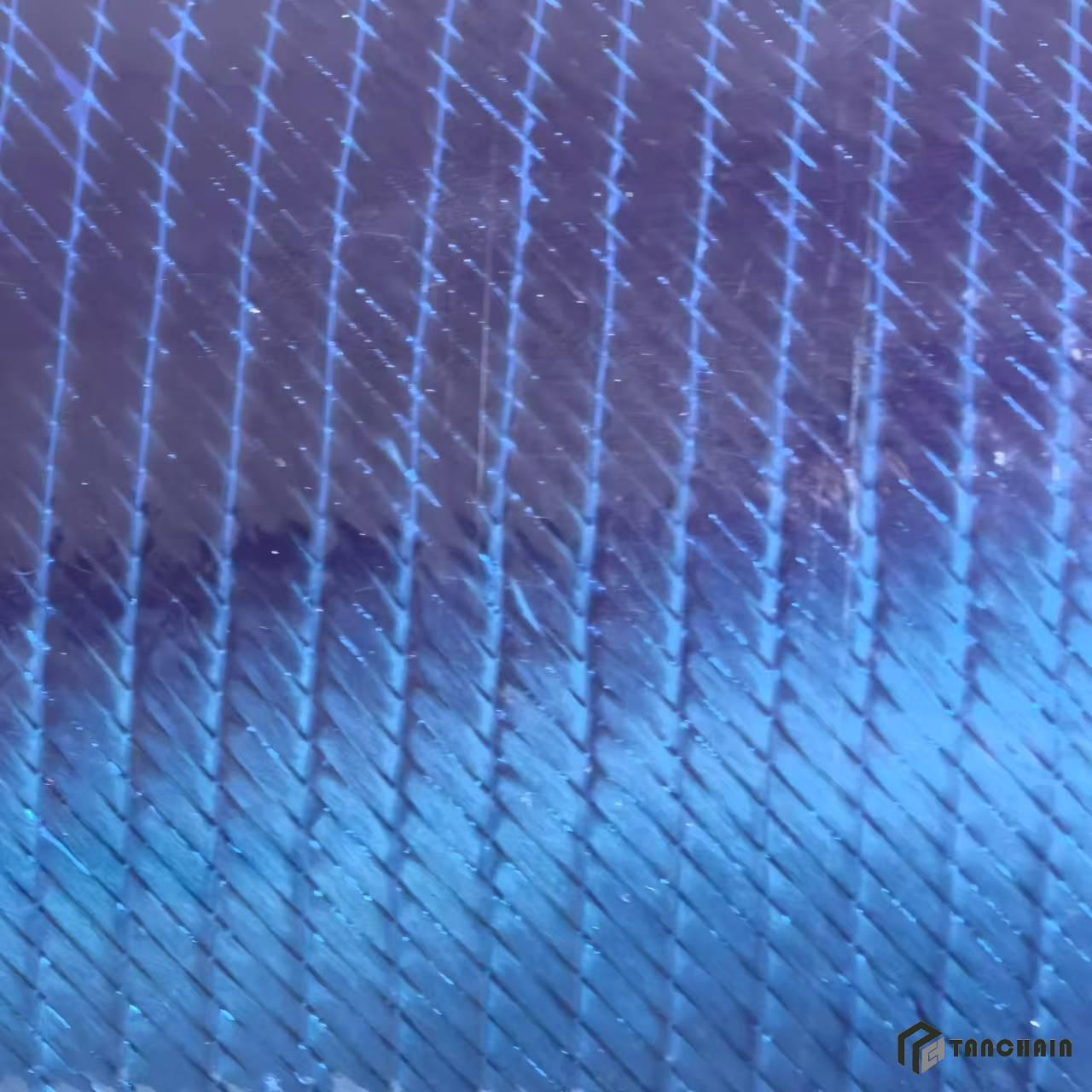

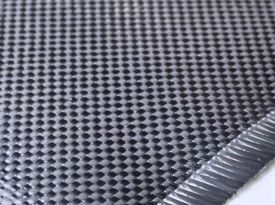

- Weave:Biaxial

- Width:127cm

SEND INQUIRY

Product Properties

Biaxial ±45° carbon fiber prepreg: Reshaping the boundaries of material performance

In the bright starry sky of composite materials, biaxial ±45° carbon fiber prepreg is undoubtedly the most dazzling star. With its excellent performance and unlimited innovation potential, it has brought unprecedented changes and breakthroughs to many fields.

Compared with traditional materials, biaxial ±45° carbon fiber prepreg shows amazing mechanical performance advantages. Its unique biaxial ±45° carbon fiber arrangement enables the material to have balanced and excellent strength and stiffness in all directions in the plane. Whether it is subjected to shear force, tension or pressure, it can cope with it calmly and provide stable and reliable support for the structure. This outstanding mechanical property not only surpasses ordinary carbon fiber materials, but also can directly replace metal materials in many application scenarios, achieving the perfect unity of lightweight and high performance of the structure.

Lightweight design is the eternal pursuit of modern industry, and biaxial ±45° carbon fiber prepreg is the ideal answer to this pursuit. It has ultra-light weight and ultra-high strength-to-weight ratio, which can greatly reduce the weight of the product without affecting its performance. In the field of aerospace, the application of this prepreg can significantly reduce the weight of aircraft, reduce fuel consumption, increase payload, and make the dream of longer range and greater load become a reality; in the automotive industry, the use of it in body parts can achieve rapid acceleration, flexible control and lower energy consumption and emissions, and achieve both driving pleasure and environmental protection.

The plasticity of biaxial ±45° carbon fiber prepreg opens up a broad space for design innovation. It can be processed into various complex geometric shapes and structural components according to different design requirements and mold shapes, from smooth curved surfaces to unique special-shaped components. This allows designers to break through the limitations of traditional materials, give full play to their creativity, and create products with unique beauty and excellent functions. Whether it is a high-performance sports car that pursues extreme aerodynamics, or a high-end medical device that requires a sophisticated and complex structure, or an architectural decoration that shows a futuristic design, it can accurately transform the design concept into an actual product, allowing imagination and reality to connect seamlessly.

In terms of quality and reliability, biaxial ±45° carbon fiber prepreg has set an industry benchmark. It adopts advanced manufacturing technology and strict quality control system to ensure that each batch of products has high consistency and stability. Whether in extremely harsh environmental conditions such as high temperature, high pressure, high humidity, or in long-term use, it can consistently maintain excellent performance, providing solid guarantee for the long-term stable operation of the product. In fields such as aerospace, high-end medical, and energy equipment that have extremely high requirements for quality and reliability, it has become the trusted choice of many companies and engineers, and is the core cornerstone for building high-quality and high-reliability products.

Biaxial ±45° carbon fiber prepreg is the crystallization of technology and technology, and the engine of innovation and breakthrough. With its unparalleled performance advantages, lightweight characteristics, strong design adaptability, and excellent quality reliability, it is reshaping the boundaries of material performance and opening up a new era of high-performance material applications. Choosing biaxial ±45° carbon fiber prepreg means choosing to go with the future, choosing to empower your products with advanced material technology, and letting your dreams fly freely in the sky of innovation.

Material: |

60% Carbon Fiber, 40% resin | Yarn (warp): | 12k carbon fiber spread tow |

| Pattern: | Biaxial ±45° | Yarn (weft): | 12k carbon fiber spread tow |

| Weight : | 330gsm(carbon fabric: 200gsm) | Width: | 127cm |

| Density(+45°): | 5.4/10cm | Thickness: | 0.3mm |

| Density(-45°): | 5.4/10cm | Color: | Black |

Material: |

60% Carbon Fiber, 40% resin |

| Pattern: | Biaxial ±45° |

| Weight : | 330gsm(carbon fabric: 200gsm) |

| Density(+45°): | 5.4/10cm |

| Density(-45°): | 5.4/10cm |

| Yarn(warp): | 3k carbon fiber spread tow |

| Yarn(weft): | 3k carbon fiber spread tow |

| Width: | 127cm |

| Thickness: | 0.3mm |

| Color | Black |

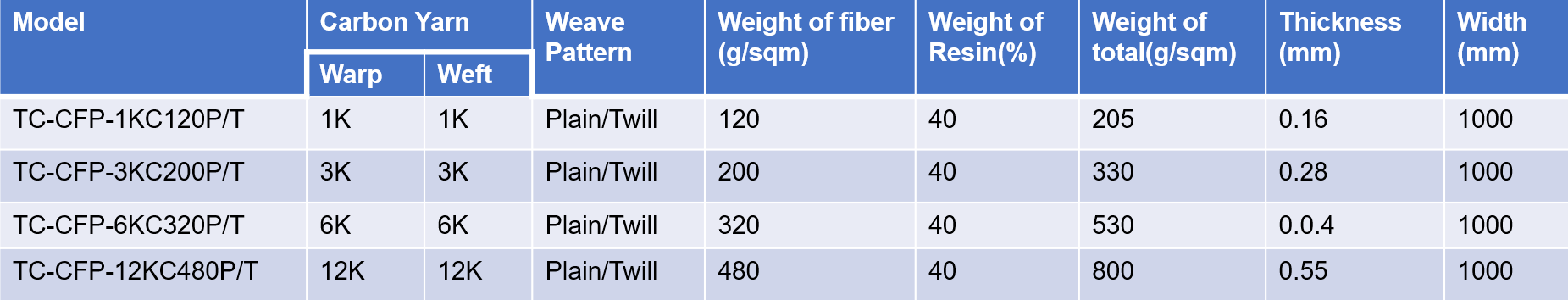

Product list of woven prepregs

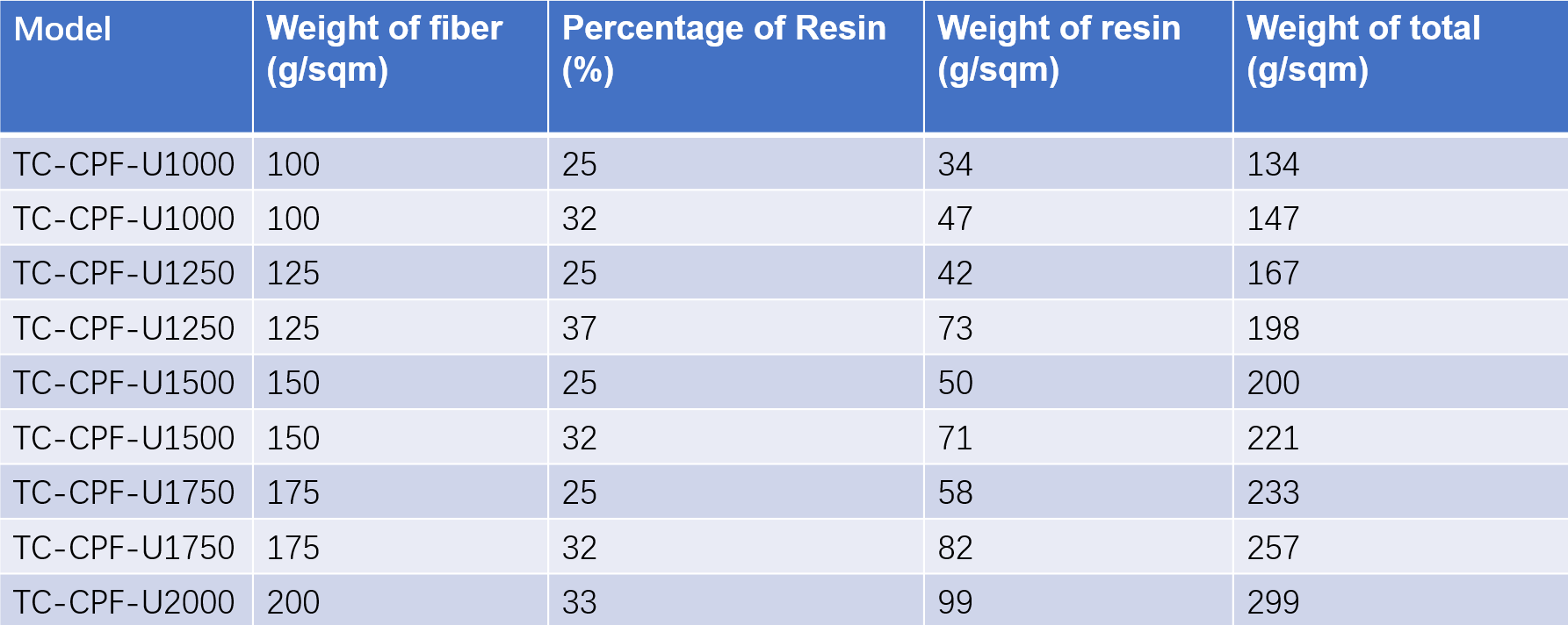

Product list of UD prepregs

SHIPPING