-

-

25K - Carbon fiber filaments

- Code:TC-CF-25K

- Material:100% Carbon Fiber

- Weight:25k filaments

- Function:High strength, Low weight.

- Color:Black

SEND INQUIRY

25K carbon fiber filament is a large tow carbon fiber product. The following are its characteristics, uses, advantages and disadvantages and development prospects:

1. Features:

- Excellent mechanical properties: It has high specific strength and high specific modulus. Specific strength refers to the ratio of the strength of a material to its density, and specific modulus refers to the ratio of the modulus of a material to its density. This means that at the same weight, the strength and stiffness of 25K carbon fiber filament are much higher than many traditional materials, such as steel and aluminum.

- Good fatigue resistance: It can withstand long-term cyclic loads without fatigue damage, and maintains good performance stability during long-term use. It is suitable for application scenarios with high requirements for material fatigue performance.

- Lightweight: Low density and light weight are of great significance for application fields that pursue lightweight, such as aerospace, automobiles and other fields. It can reduce the overall weight of equipment, reduce energy consumption and improve operating efficiency.

- Corrosion resistance and high temperature resistance: It has good chemical stability and can maintain good performance in corrosive environments such as acids, alkalis and salts; at the same time, it can work normally at higher temperatures, and its high temperature resistance makes it advantageous for application in high temperature environments.

- Good conductivity: Carbon fiber has good conductivity and can be used in places where conductivity is required, such as electronic equipment, antistatic materials, etc.

- Small thermal expansion coefficient: The thermal expansion coefficient is low, and the size changes less when the temperature changes, which is very important for some application scenarios with high dimensional accuracy requirements, such as precision instruments, optical equipment, etc.

2. Main uses:

- Aerospace field: It can be used to manufacture aircraft wings, fuselage structural parts, engine parts, etc., which can reduce the weight of the aircraft, improve fuel efficiency, increase flight mileage and load capacity. For example, some structural parts of some new aircraft are made of carbon fiber materials, and the weight is reduced by 20% - 30%.

- Automobile industry: It is used in the body structure, chassis parts, engine hood, etc. of the car, which can reduce the overall weight of the car and improve the acceleration performance, handling performance and fuel economy of the car. With the development trend of lightweight cars, carbon fiber has broad application prospects in the automotive industry.

- Sports goods: It is widely used in the manufacture of sports equipment such as golf clubs, tennis rackets, bicycles, skis, etc., which can improve the performance and service life of sports equipment and provide athletes with a better use experience.

- Construction field: It can be used for the reinforcement and repair of building structures, such as the reinforcement of beams and columns of bridges and buildings, which can improve the bearing capacity and seismic resistance of building structures; it can also be used for the decoration of the facade of buildings, giving the buildings a unique appearance.

- New energy field: In the manufacture of wind power blades, 25K carbon fiber filaments can enhance the strength and stiffness of blades, improve the wind resistance and service life of blades; in the support structure of solar panels, carbon fiber materials can also be used to reduce weight and improve structural stability.

3. Advantages and disadvantages:

- Advantages:

- Excellent performance: It combines the above-mentioned excellent performances and has irreplaceable advantages in many fields, which can meet the high requirements of material performance in high-end application fields.

- High design flexibility: It can be made into products of various shapes and sizes through different molding processes, such as weaving, winding, pultrusion, etc., to meet the design requirements of different application scenarios.

- Recyclability: After the service life of carbon fiber materials, they can be recycled and reused through certain processes to reduce the impact on the environment and meet the requirements of sustainable development.

- Disadvantages:

- High cost: The production process is complex and the equipment investment is large, resulting in a high production cost of 25K carbon fiber filament and a relatively expensive price, which to a certain extent limits its application in some cost-sensitive fields.

- Brittleness: Although it has high strength, carbon fiber is brittle and prone to breakage when subjected to large impact or shear force, which requires attention during design and use.

- Difficult processing: Due to the high hardness of carbon fiber, special processing equipment and tools are required during processing, which makes processing difficult and requires high processing technology and technology.

4. Development prospects:

- Demand growth: With the increasing global demand for high-performance materials and the increasingly urgent demand for lightweight and high-strength materials in various application fields, the market demand for 25K carbon fiber filament will show a trend of sustained growth. Especially in the fields of aerospace, automobiles, new energy, etc., the demand for carbon fiber will continue to expand.

- Technological progress: With the continuous advancement of carbon fiber production technology, production efficiency will continue to improve and costs will gradually decrease, which will help expand the scope of application of carbon fiber. At the same time, the development of higher-performance carbon fiber products is also the future development direction, which will further meet the market demand for high-performance materials.

- Application field expansion: In addition to the existing application fields, the application of 25K carbon fiber filament in the fields of medical, electronics, environmental protection, etc. will also continue to expand. For example, in the medical field, carbon fiber can be used to manufacture medical devices and prostheses; in the electronics field, it can be used to manufacture high-performance electronic equipment housings and heat dissipation components.

- Accelerated localization process: At present, my country's carbon fiber industry is developing rapidly, the production technology and product quality of domestic enterprises are constantly improving, and the localization process is accelerating. This will help reduce my country's dependence on imported carbon fiber, improve the competitiveness of my country's carbon fiber industry, and promote the widespread application of 25K carbon fiber filament.

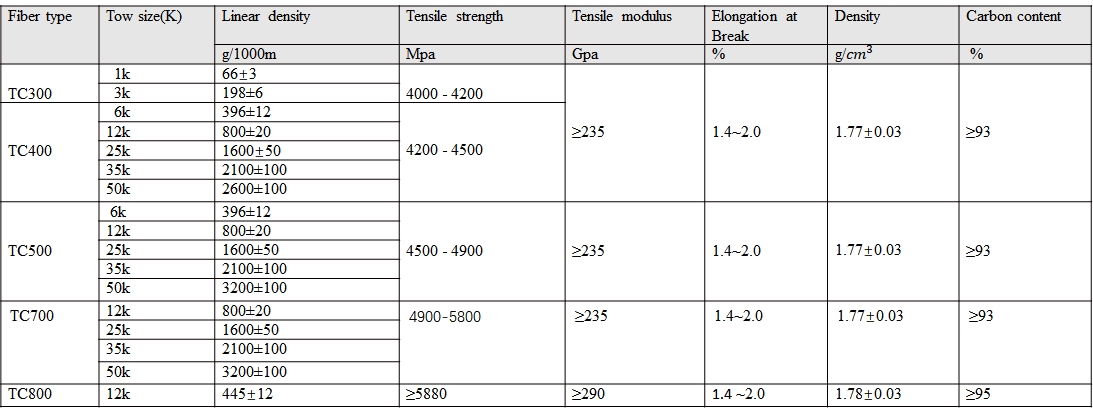

Technical Data

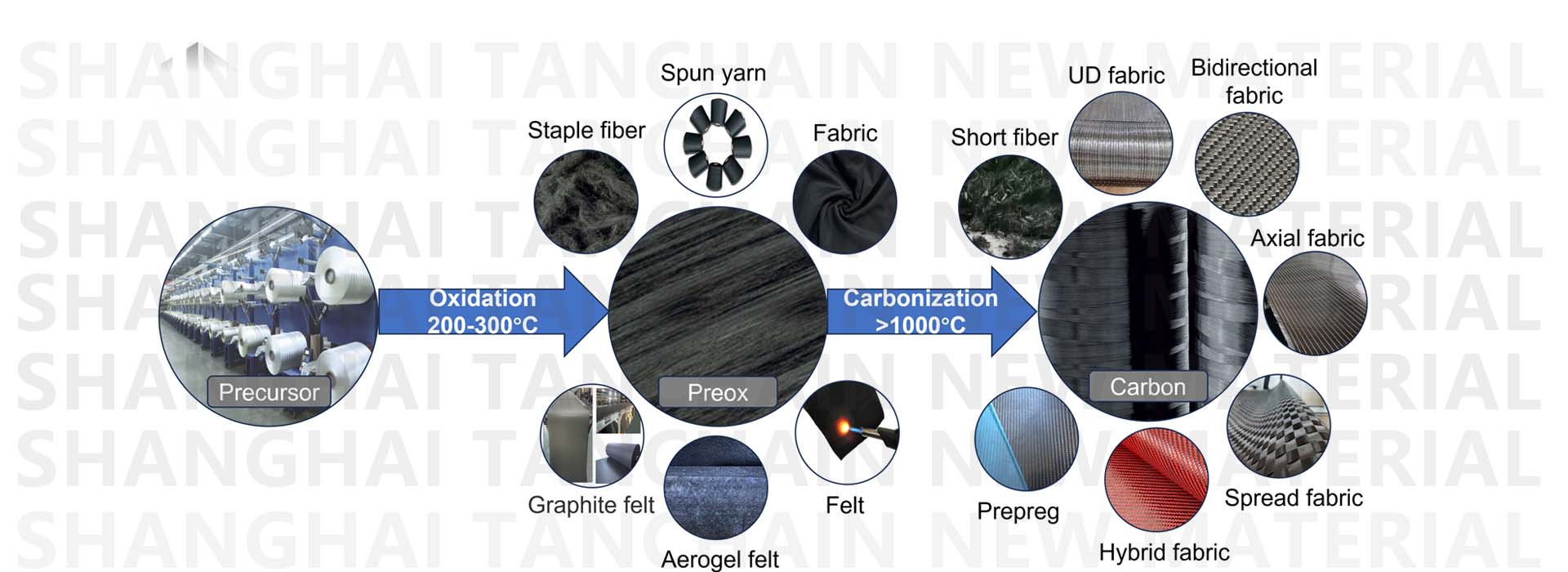

Production Line

Tanchain's Production Flow

SHIPPING