-

-

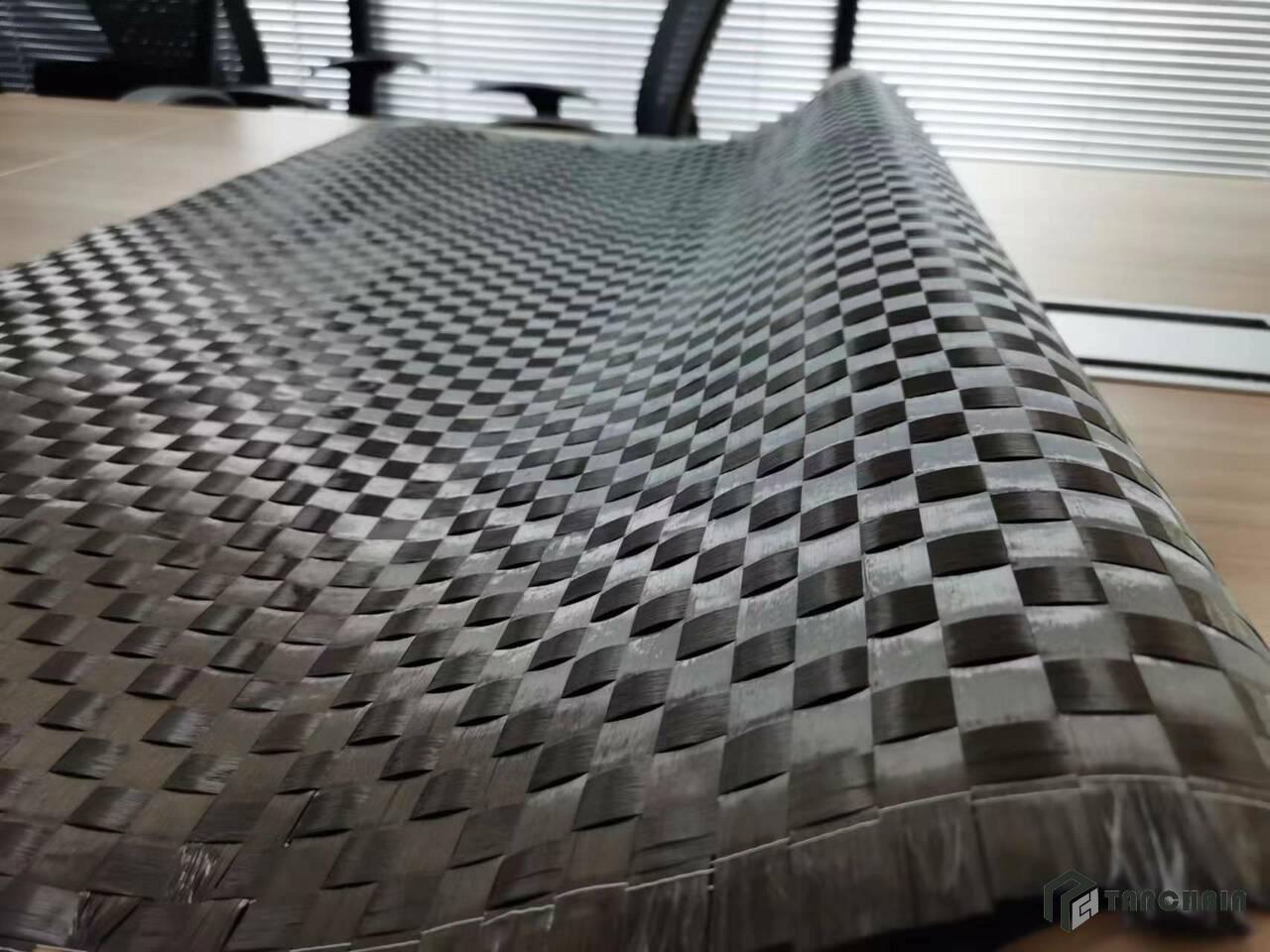

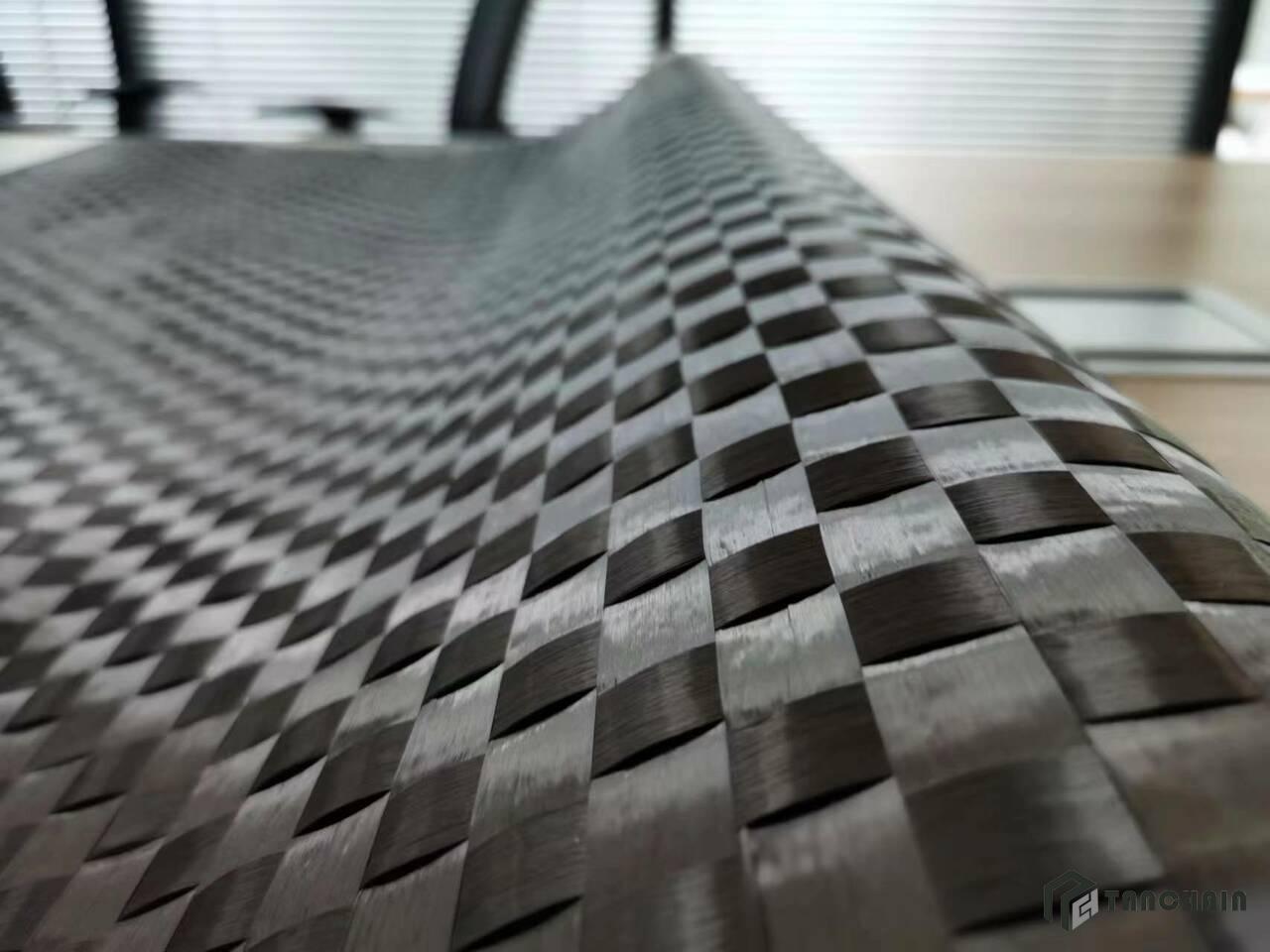

T700 - 200gsm - spread tow carbon fabric, plain weave

- Code:TC-CF-S200P

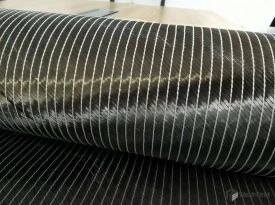

- Material:12k T700 carbon fabric

- Weight:80g, 100g, 160g, 200g etc.

- Function:Reinforcement, exterior, interior, surface

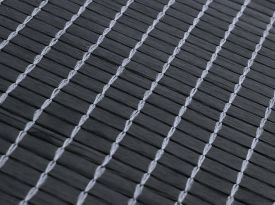

- Weave:Plain, Twill

- Width:100cm

SEND INQUIRY

200g carbon fiber widening fabric has the following characteristics:

1. Physical properties:

- Light weight: The weight per square meter is 200g. Compared with traditional metal materials, its weight advantage is obvious, which is convenient for handling, installation and construction. It is of great significance to reduce the weight of the overall structure, especially suitable for application scenarios with strict weight requirements.

- Thin thickness: The general thickness is about 0.211mm. The thinner thickness enables it to better fit the surface of objects of various shapes, which has advantages in some occasions where space is limited or close fitting is required.

- Good widening: After widening treatment, the width of the fabric increases, which can reduce the number of splicing, improve construction efficiency, and better cover large areas.

2. Mechanical properties:

- High strength: It has a high tensile strength, usually between 3600MPa and 4000MPa. Although it is slightly lower than the strength of 300g carbon fiber cloth, it is still much higher than many traditional materials. It can withstand large tensile forces and provide good reinforcement and support for the structure.

- Good flexibility: The fiber density is relatively small, which makes it more flexible, easier to bend and deform, and can adapt to complex curved structures, which has advantages when wrapping special-shaped components.

3. Chemical properties:

- Corrosion resistance: Carbon fiber materials have excellent corrosion resistance and can be used stably for a long time in harsh chemical environments such as acids, alkalis, and salts. They are not easily corroded by chemicals, which prolongs their service life.

- High temperature resistance: It has high high temperature resistance and can still maintain good performance stability in high temperature environments. It is suitable for some occasions with special temperature requirements.

4. Other characteristics:

- Good processability: It can be cut, sewn and other processing operations as needed, which is convenient for construction and installation in different application scenarios.

- Good conductivity: Carbon fiber itself has good conductivity. This feature makes it have application potential in some fields that require conductivity or anti-static, but in some scenarios with strict requirements on conductivity, it is necessary to pay attention to insulation treatment.

200g carbon fiber widening fabric has a wide range of application scenarios, including:

1. Construction field:

- Building reinforcement: It can be used to reinforce structures such as beams, plates, and columns to improve the bearing capacity and seismic resistance of the structure. For example, in the renovation and repair of old buildings, it can enhance the strength and stability of the structure.

- Crack repair: For cracks in building structures, carbon fiber widening fabric can be pasted on the cracks to repair and reinforce them to prevent further expansion of the cracks.

- Curved structure construction: Due to its good flexibility and widening, it is suitable for the reinforcement and repair of curved structures such as bridges and tunnels. It can better fit the surface of the structure and improve the reinforcement effect.

2. Aerospace field:

In aerospace equipment such as aircraft and satellites, it can be used to manufacture components such as fuselages, wings, and engine blades. Its lightweight and high-strength characteristics can be used to reduce the weight of the aircraft and improve flight performance and fuel efficiency.

3. Automotive industry: It can be used to manufacture car bodies, chassis, engine hoods and other parts to reduce the weight of cars, improve the acceleration performance, fuel economy and handling of cars, and can also be used for car modification, such as modifying surrounds, interiors and other parts.

4. Sports goods:

It can be used to manufacture sports equipment such as bicycles, golf clubs, fishing rods, rackets, ski poles, etc., which can improve the strength and lightness of the equipment and enhance the athletes' experience.

5. Electronic and electrical fields:

Due to its good conductivity, it can be used to manufacture electronic equipment housings, radiators, electromagnetic shielding materials, etc., to meet the special requirements of electronic equipment for materials.

6. Industrial field:

In wind power generation equipment, it can be used to manufacture blades and other parts to improve the strength and weather resistance of blades; in machinery manufacturing, it can be used to manufacture some key parts to improve the performance and service life of machinery.

| Carbon fiber | T700 12k, 24k |

| Weight |

80g, 100g, 160g, 200g etc. |

| Structure | Twill, Plain |

| Application | Sports, Aerospace, Automobile etc. |

| Feature | beautiful appearance, high strength |

Characteristics of T700 carbon fabrics:

| Yarn width | 8mm |

| Weight | 200gsm |

| Thickness | 0.22mm |

| Carbon fiber | T700 |

APPLICATIONS