-

-

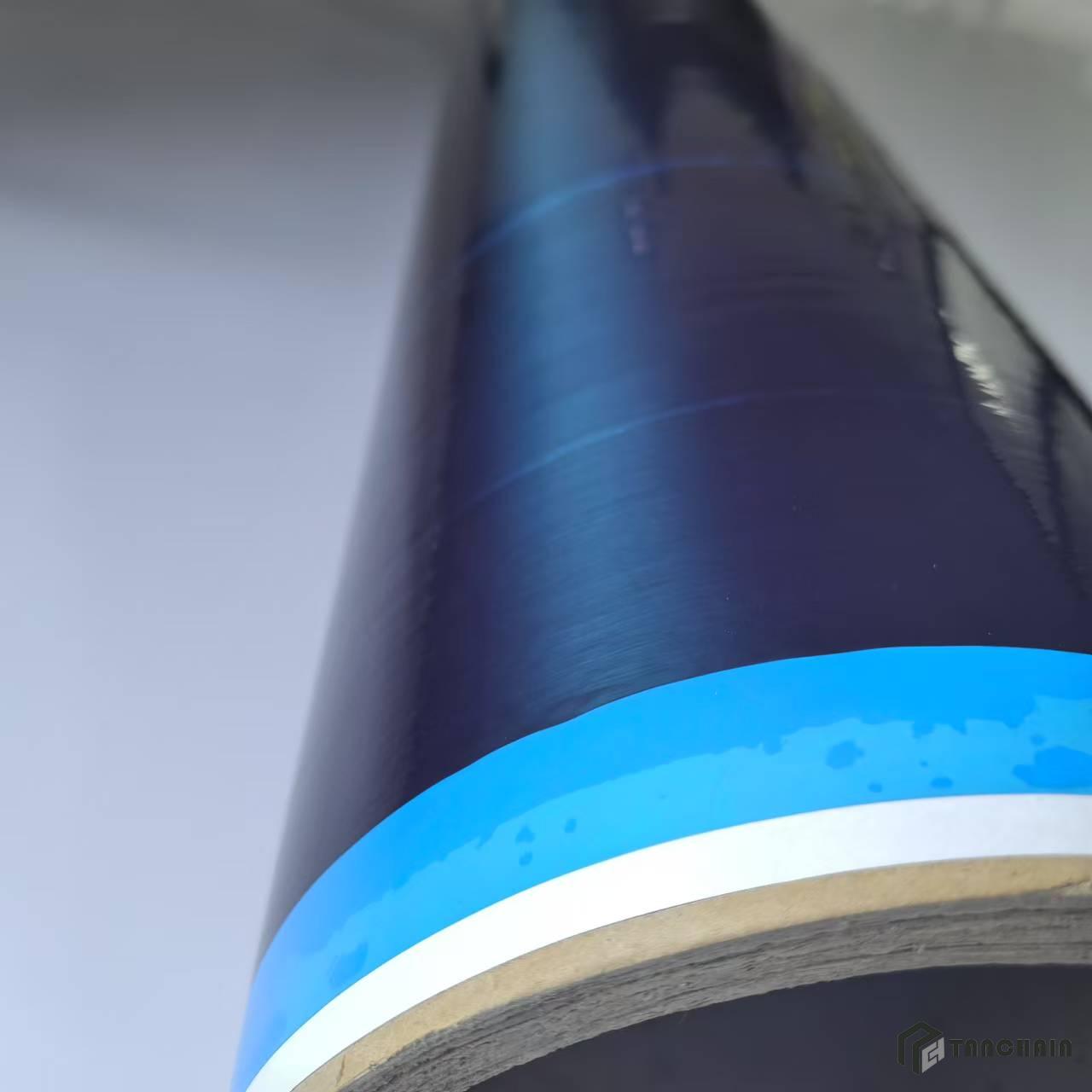

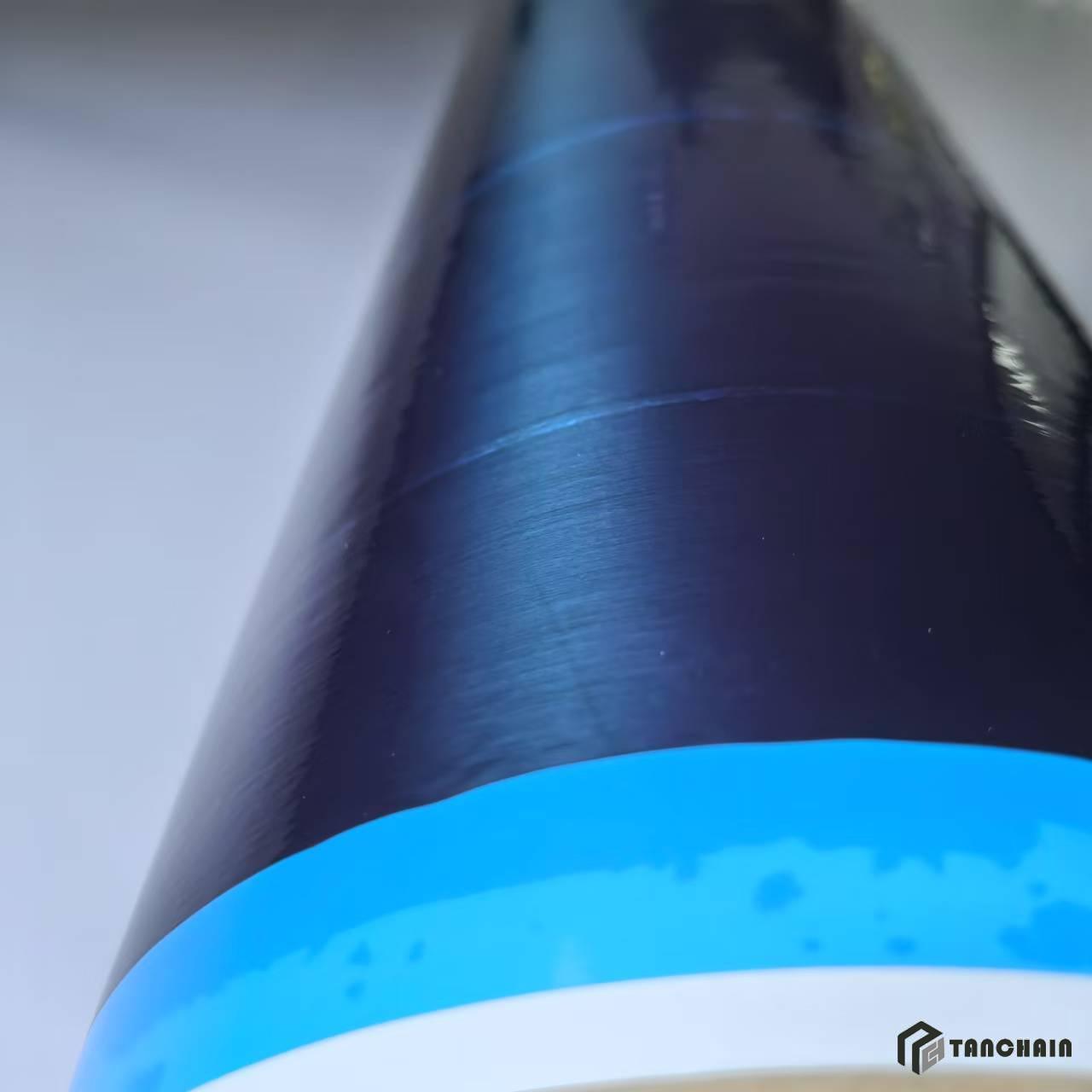

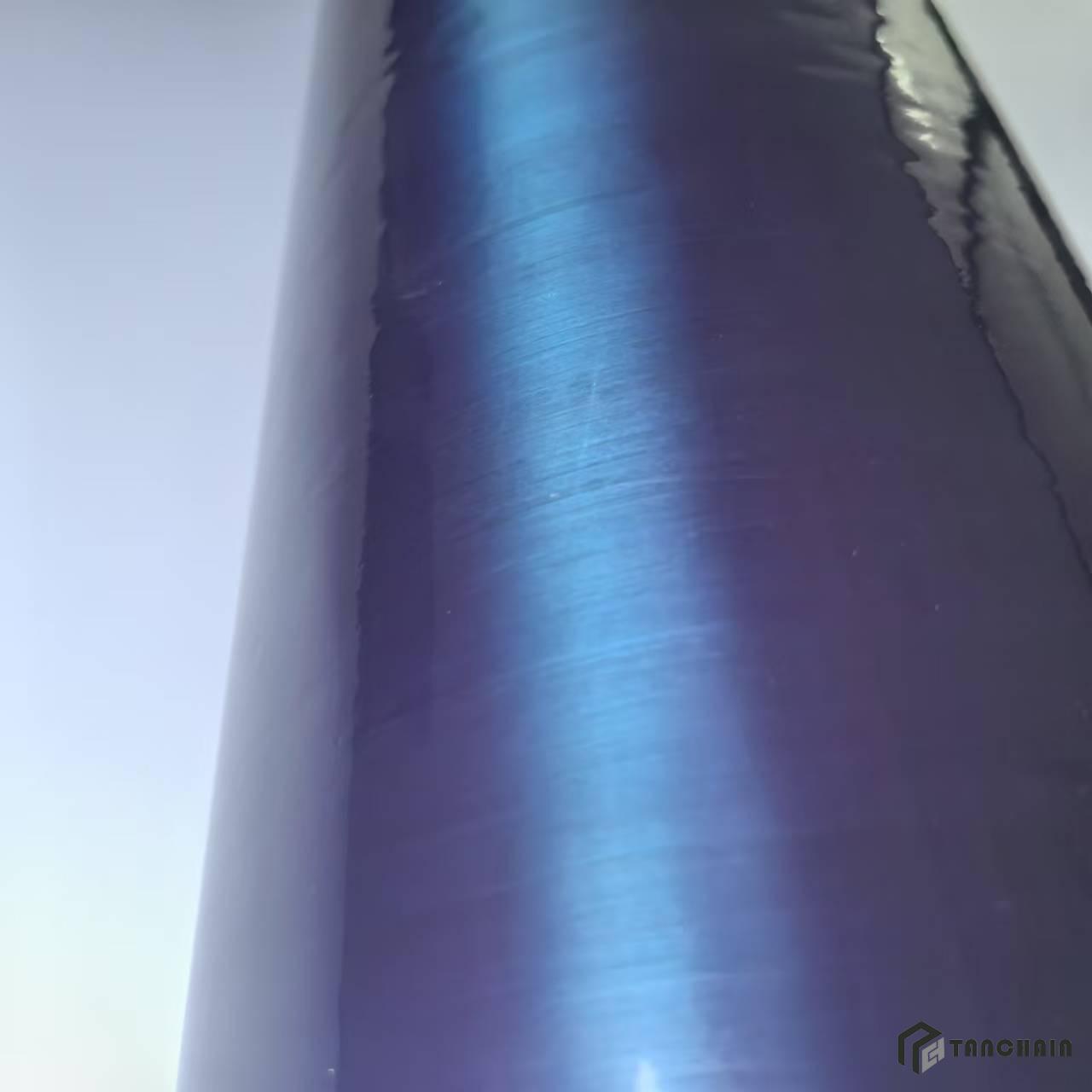

299gsm - Unidirectional PAN Oxidized Fiber Prepreg - pre-oxidized - fiber - 200g

- Code:TC-PXP-U2000

- Material:67% T400 Pre-Oxidized Fiber, 33% resin

- Weight:299gsm

- Function:High strengh, Non-conductive

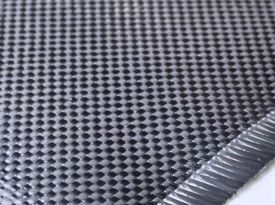

- Color:Black

- Weave:Unidirectional

- Width:100cm

SEND INQUIRY

Product Properties

Preoxidized fiber unidirectional prepreg is a high-performance composite intermediate material. The following is its introduction:

Basic concept

Preoxidized fiber unidirectional prepreg is a unidirectional prepreg made by using preoxidized fiber as a reinforcing material and thermosetting or thermoplastic resin as a matrix. The preoxidized fiber is an intermediate product of carbon fiber. After preoxidation treatment at 200℃-300℃, it has certain heat resistance and chemical stability.

Features

- Non-conductive: Compared with carbon fiber prepreg, preoxidized fiber prepreg has the characteristics of non-conductive, so it will not shield electromagnetic signals and can be used in some special fields.

- High strength and high modulus: Preoxidized fiber itself has high strength and modulus. After being made into unidirectional prepreg, it can provide excellent mechanical properties in the direction of fiber arrangement, can withstand large tension and pressure, and meet the application scenarios with high requirements for material strength.

- Good heat resistance: The pre-oxidation treatment of the pre-oxidized fiber makes its heat resistance better than that of ordinary fibers. With the high-temperature resistant resin matrix, the unidirectional prepreg can still maintain good mechanical properties and dimensional stability in a high-temperature environment, and can be used in the manufacture of components in a high-temperature working environment.

- Excellent chemical corrosion resistance: It has good tolerance to chemical substances such as acids and alkalis. When used in some harsh chemical environments, it can effectively prevent the material from being corroded and extend its service life.

Preparation method

- Solution impregnation method: The pre-oxidized fiber is impregnated in a solution containing resin to allow the resin to fully penetrate into the fiber, and then the solvent is volatilized by heating and other methods to obtain a prepreg. This method requires less equipment investment, but the resin content is difficult to accurately control, and a large amount of solvent volatilization will cause environmental pollution.

- Hot melt adhesive film method: First, the molten resin is made into a uniform and flat adhesive film, and then the adhesive film and the pre-oxidized fiber are compositely impregnated at a certain temperature and pressure to melt the resin and impregnate it into the fiber to form a prepreg. The advantages of this process are accurate control of resin content, low volatility, and no environmental pollution.

Material: |

67% Oxidized Fiber, 33% resin | Yarn (warp): | 12k oxidized fiber |

| Pattern: | Unidirectional | Yarn (weft): | NA |

| Weight : | 299gsm(oxidized fiber: 200gsm) | Width: | 100cm |

| Color: | Black | Thickness: | 0.15mm |

Material: |

67% Oxidized Fiber, 33% resin |

| Pattern: | Unidirectional |

| Weight : | 299gsm(oxidized fiber: 200gsm) |

| Yarn(warp): | 12k oxidized fiber |

| Yarn(weft): | NA |

| Width: | 100cm |

| Thickness: | 0.15mm |

| Color | Black |

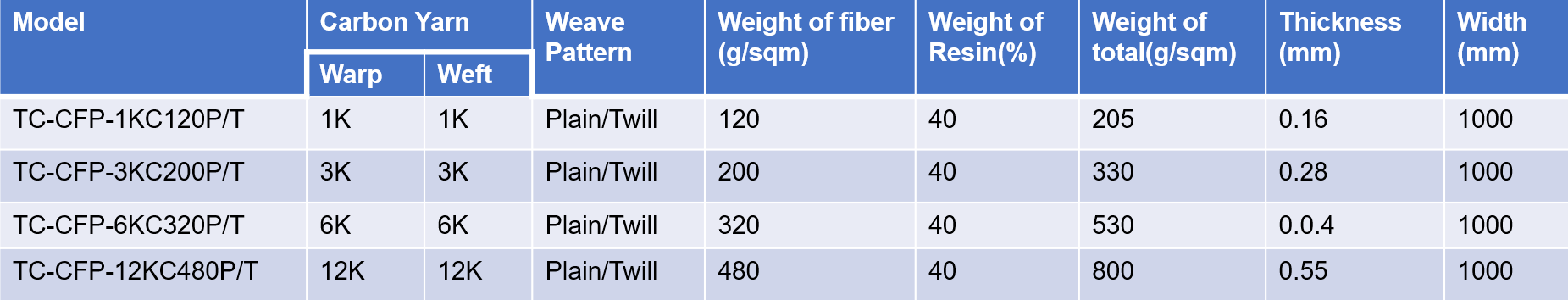

Product list of woven prepregs

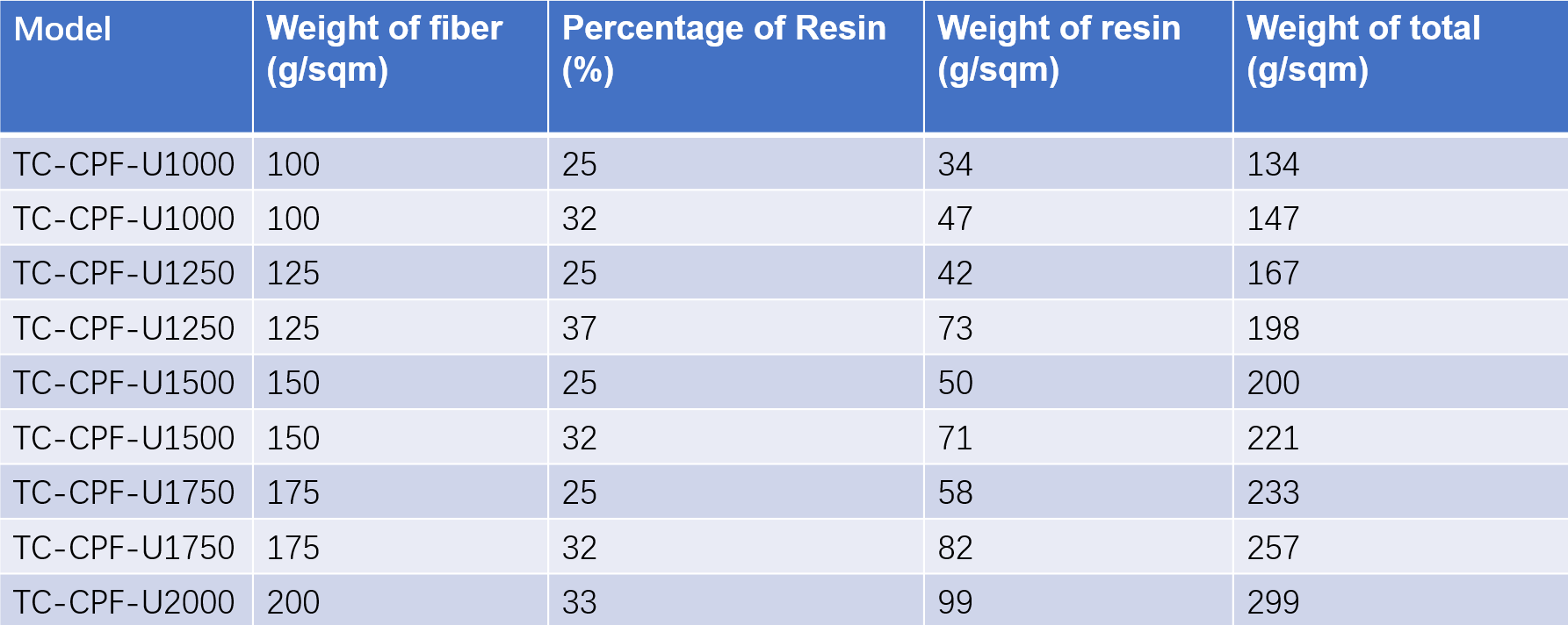

Product list of UD prepregs

SHIPPING