-

-

3K - 345gsm - Plain Carbon Fiber Prepreg - T300 - 200g - plain - fabric

- Code:TC-CFP-3KC200P

- Material:58% Carbon Fiber Fabric, 42% resin

- Weight:345gsm

- Function:High strengh, Low weight, Good looking, High modulus, Low thermal expansion

- Color:Black

- Weave:Twill

- Width:100cm

SEND INQUIRY

Product Properties

345g plain carbon fiber prepreg has the following characteristics:

- Composition: 58% plain, dry carbon fabric, 42% epoxy resin.

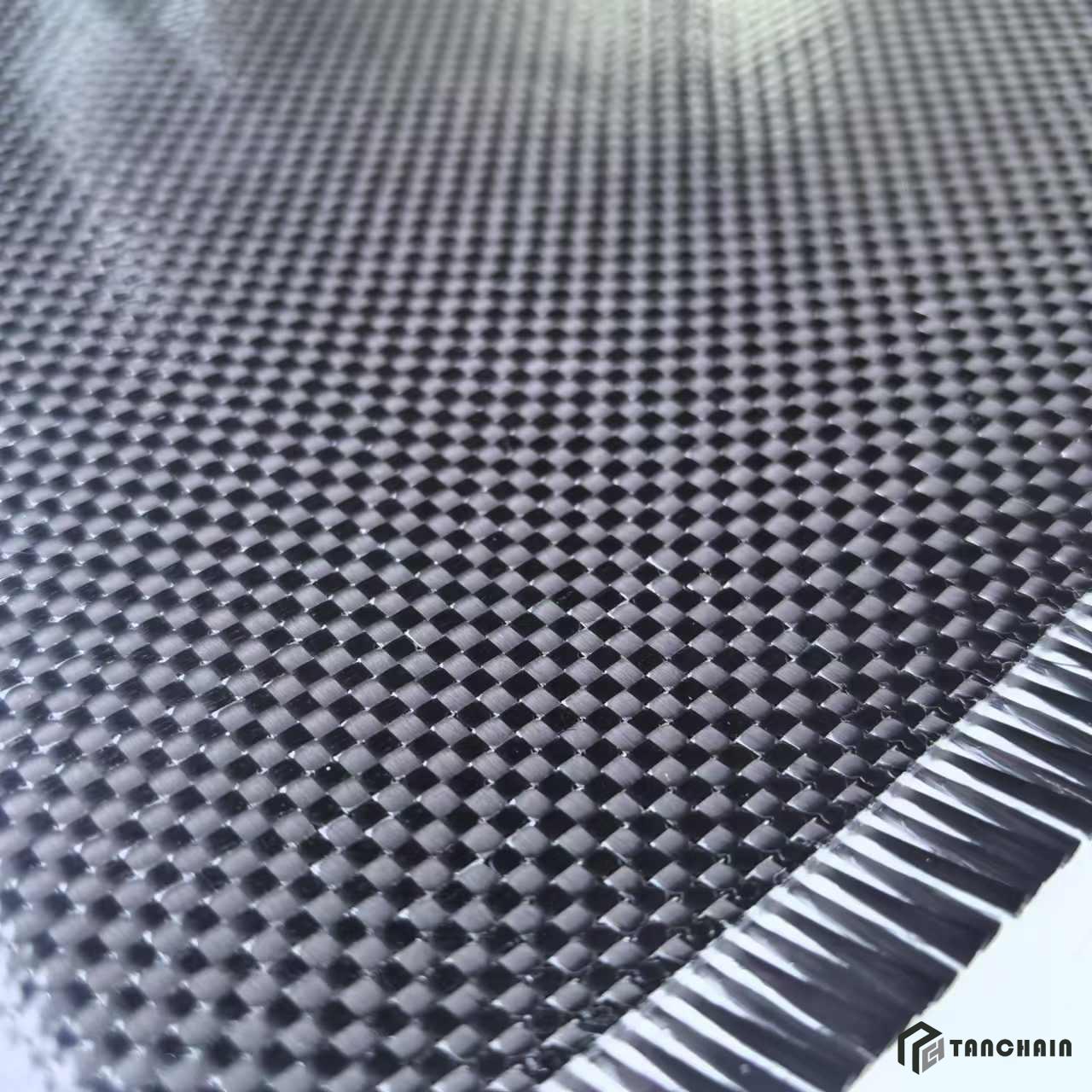

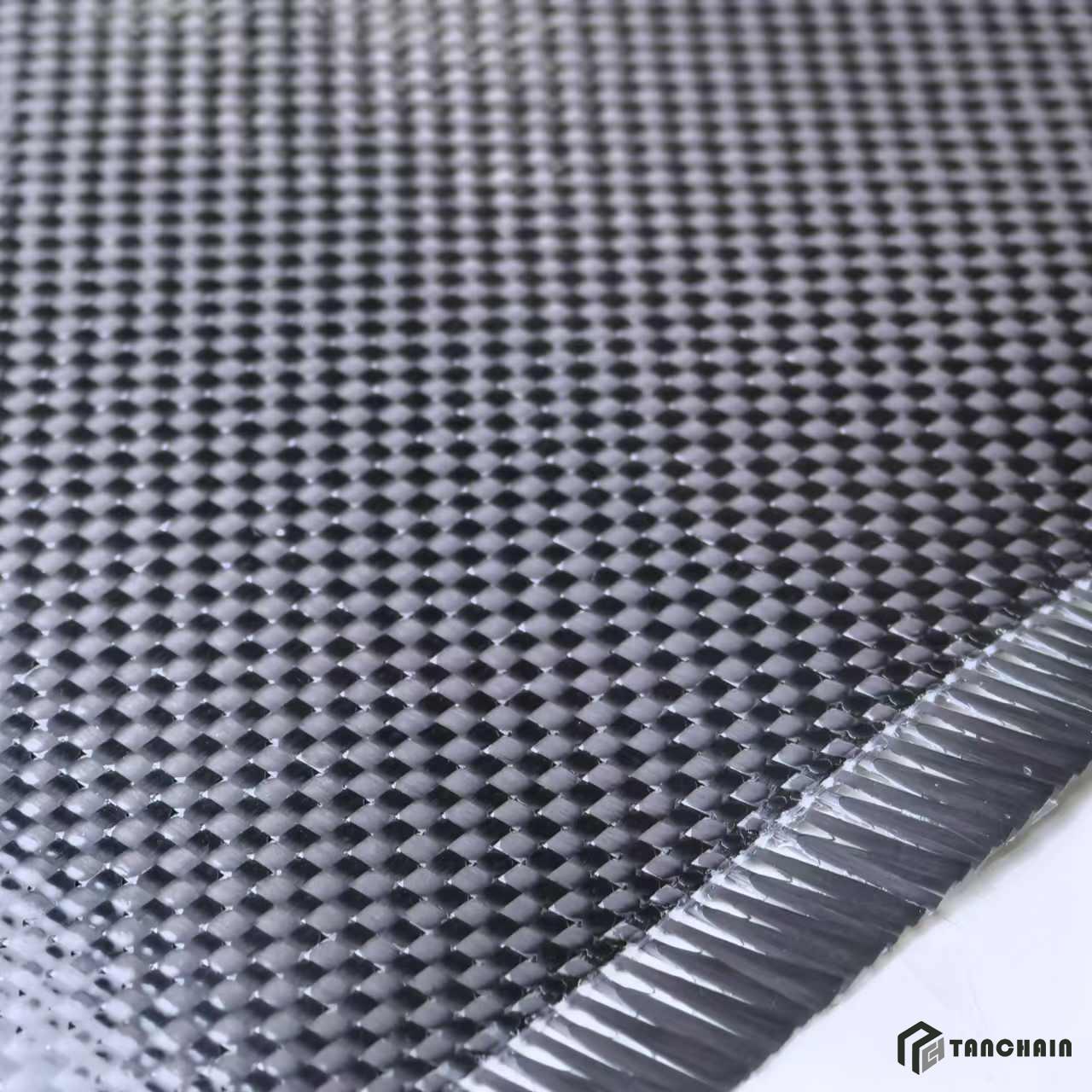

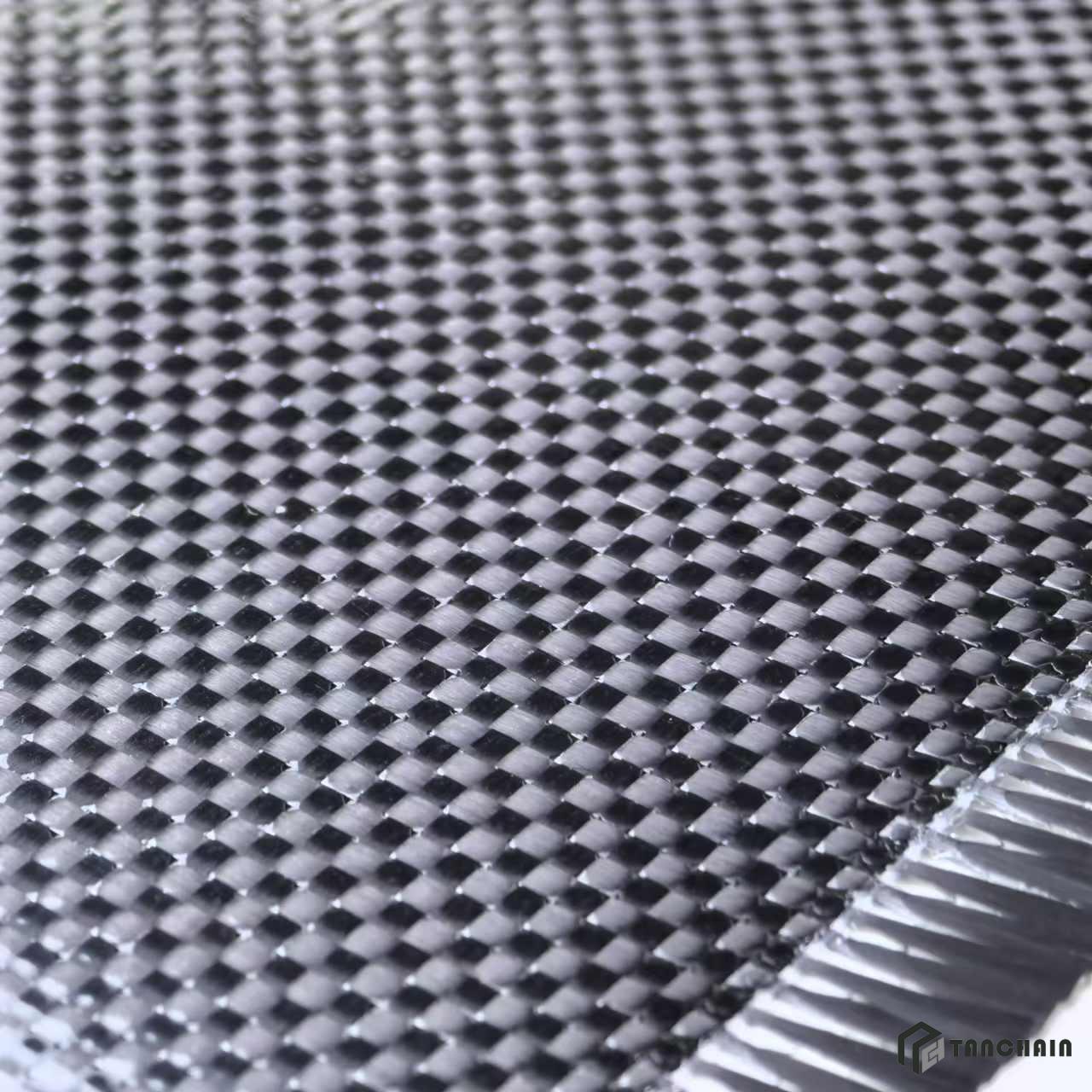

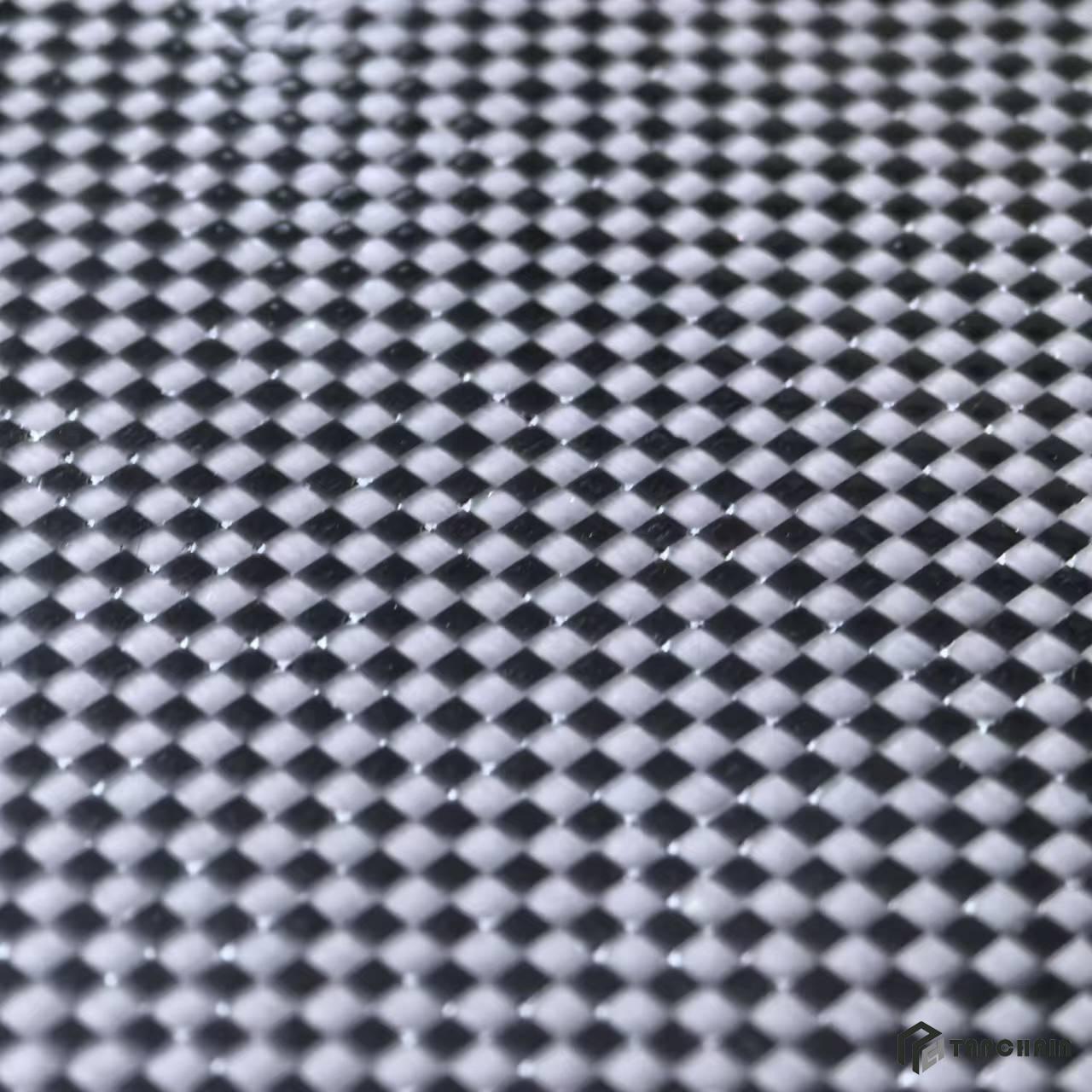

- Good mechanical properties: the plain weave method makes the carbon fiber yarn interlaced at many points, the prepreg is stronger and smoother, has a higher elongation when subjected to external tensile force, can withstand a certain degree of tension in different directions, and has stable mechanical properties.

- Light weight: the specific gravity is only 1/5 to 1/4 of that of steel, and basically does not increase the weight of the component. It has obvious advantages in application scenarios with strict weight requirements, such as the aerospace field.

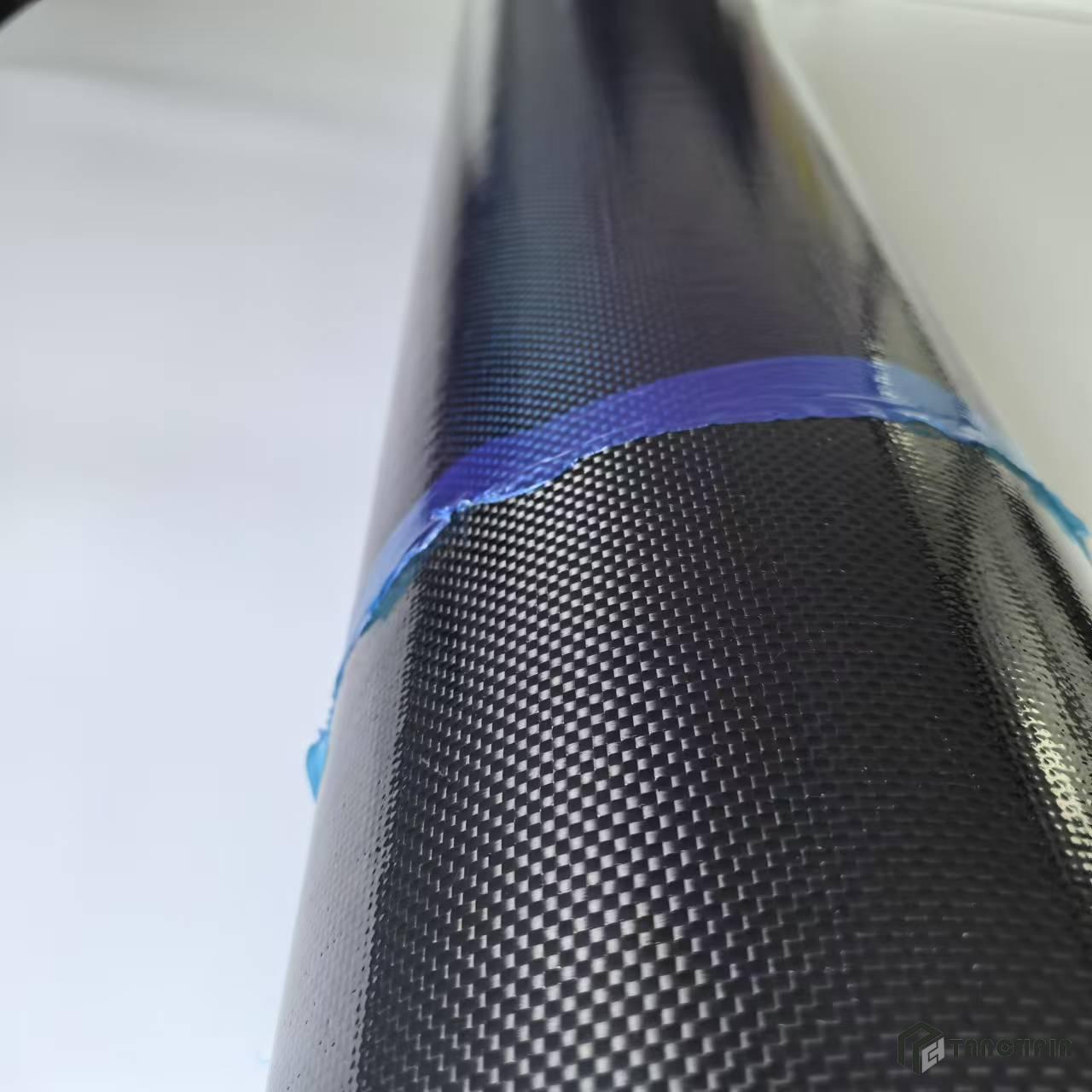

- Strong processability: soft texture, can be cut freely, can adapt to components of various shapes, and can be bent and wound to form, which is easy to process into complex products, such as the reinforcement of curved surfaces and special-shaped components.

- Good corrosion resistance: It has excellent acid and alkali corrosion resistance, is not easily damaged when used in harsh environments, can effectively extend the service life of the product, and is suitable for corrosive environments such as outdoor and chemical industries.

- Smooth and beautiful appearance: the surface texture of the plain weave is regular and delicate. In some products with high requirements for appearance, such as high-end sports equipment and automotive interiors, it can improve the overall beauty of the product.

It has a wide range of uses, mainly including the following fields:

Aerospace

It is used to manufacture aircraft wings, fuselage structural parts, as well as the central bearing tube, base plate, connecting frame, etc. of satellites, which can reduce weight while ensuring that the structure has sufficient strength and stability to withstand complex stress.

Automotive industry

It can be used to manufacture high-performance automobile body, chassis, transmission shaft and other parts, reduce body weight, improve vehicle acceleration performance, handling performance and fuel economy, and can also be used for automotive interior parts to increase aesthetics and durability.

Sports equipment

It is suitable for making high-end bicycle frames, golf clubs, tennis rackets, fishing rods, etc., which can optimize the weight distribution and performance of equipment, improve the user experience and competitive level.

Industrial field

It can be used to manufacture wind turbine blades. Its high strength and fatigue resistance can meet the requirements of large blades. It can also be used as structural materials for industrial equipment such as robotic arms, providing higher stiffness and strength to ensure the stability of equipment in high-precision operations.

Construction engineering

It can be used to reinforce concrete structures and wooden structures, such as bridge structure reinforcement, carbon fiber tube frame, etc., which can effectively improve the bearing capacity, seismic resistance and durability of components.

Material: |

58% Carbon Fiber, 42% resin | Yarn (warp): | 3k carbon fiber |

| Pattern: | Plain | Yarn (weft): | 3k carbon fiber |

| Weight : | 345gsm(carbon fabric: 200gsm) | Width: | 100cm |

| Density(warp): | 5/10cm | Thickness: | 0.32mm |

| Density(weft): | 5/10cm | Color: | Black |

Material: |

58% Carbon Fiber, 42% resin |

| Pattern: | Plain |

| Weight : | 330gsm(carbon fabric: 200gsm) |

| Density(warp): | 5/10cm |

| Density(weft): | 5/10cm |

| Yarn (warp): | 3k carbon fiber |

| Yarn (weft): | 3k carbon fiber |

| Width: | 100cm |

| Thickness: | 0.32mm |

| Color | Black |

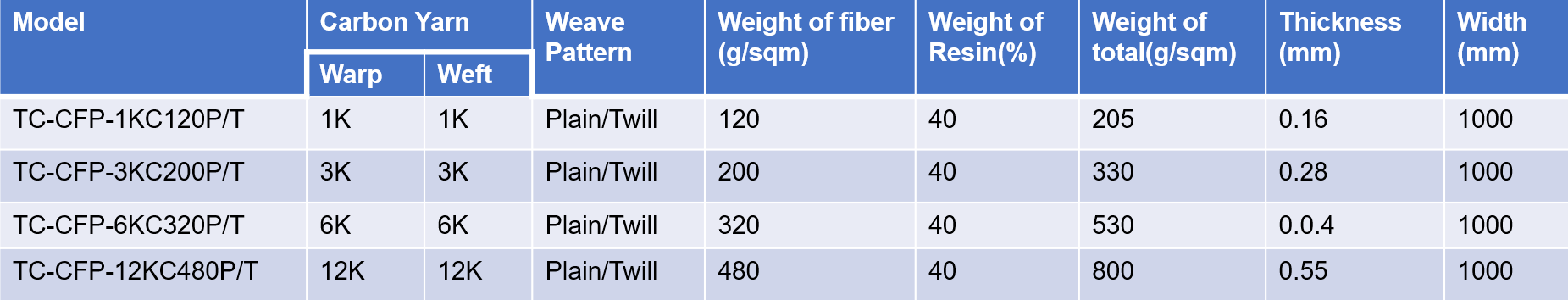

Product list of woven prepregs

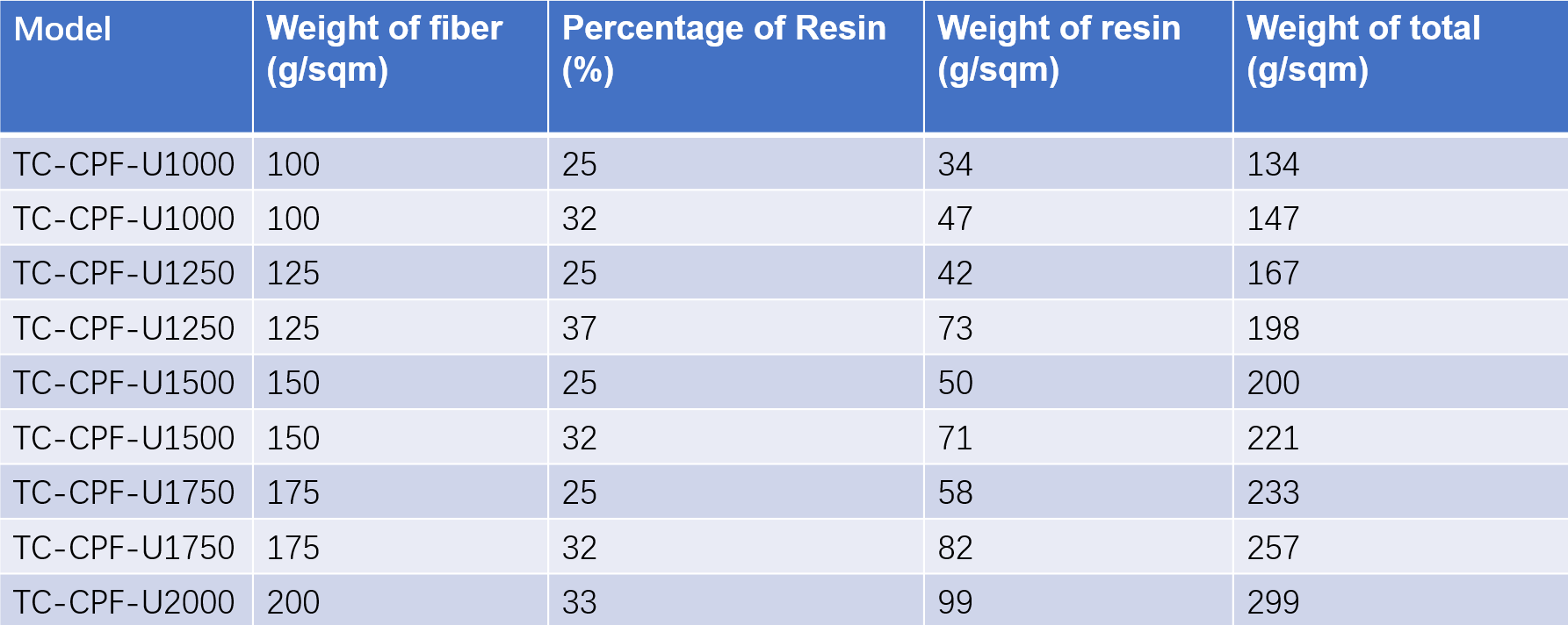

Product list of UD prepregs

SHIPPING