-

-

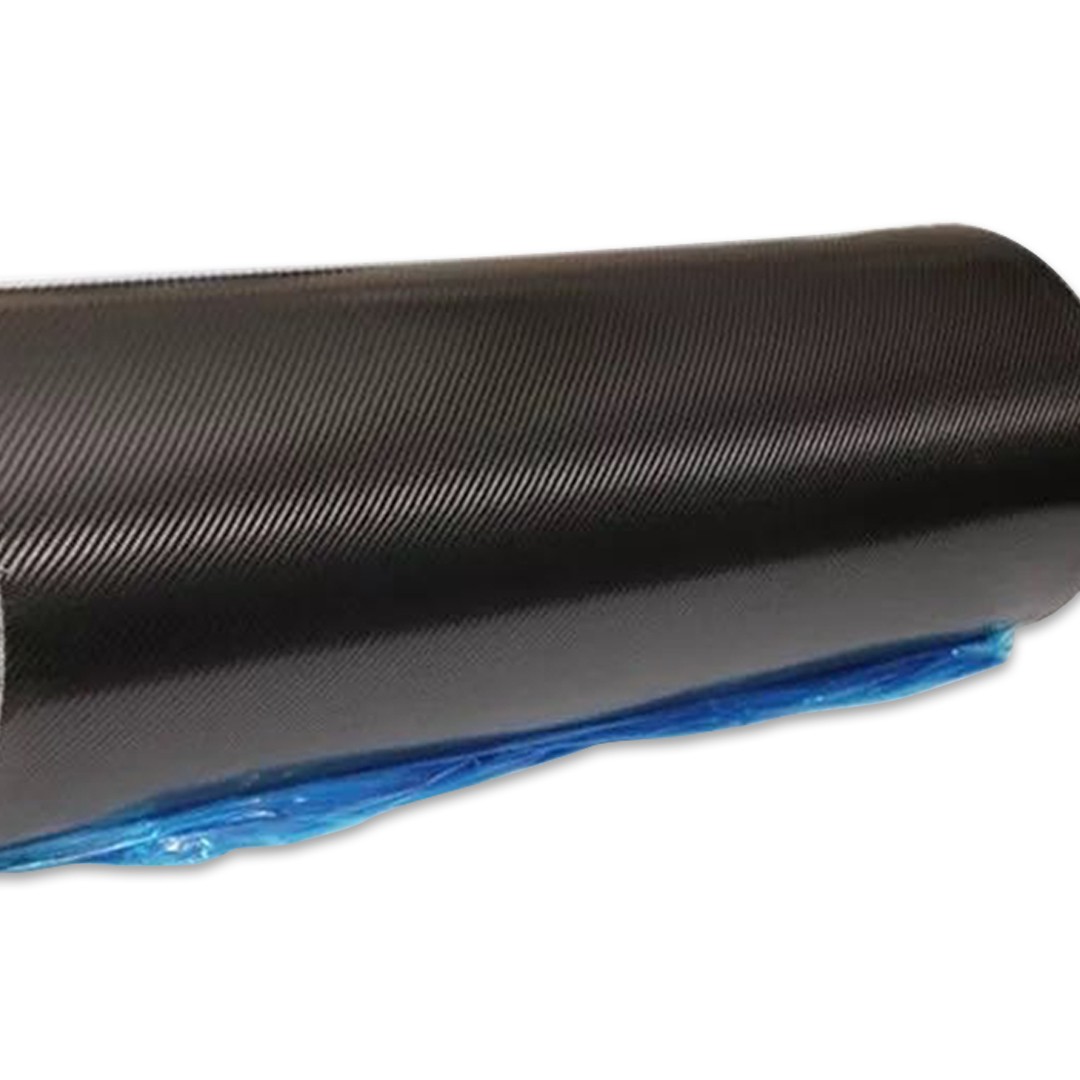

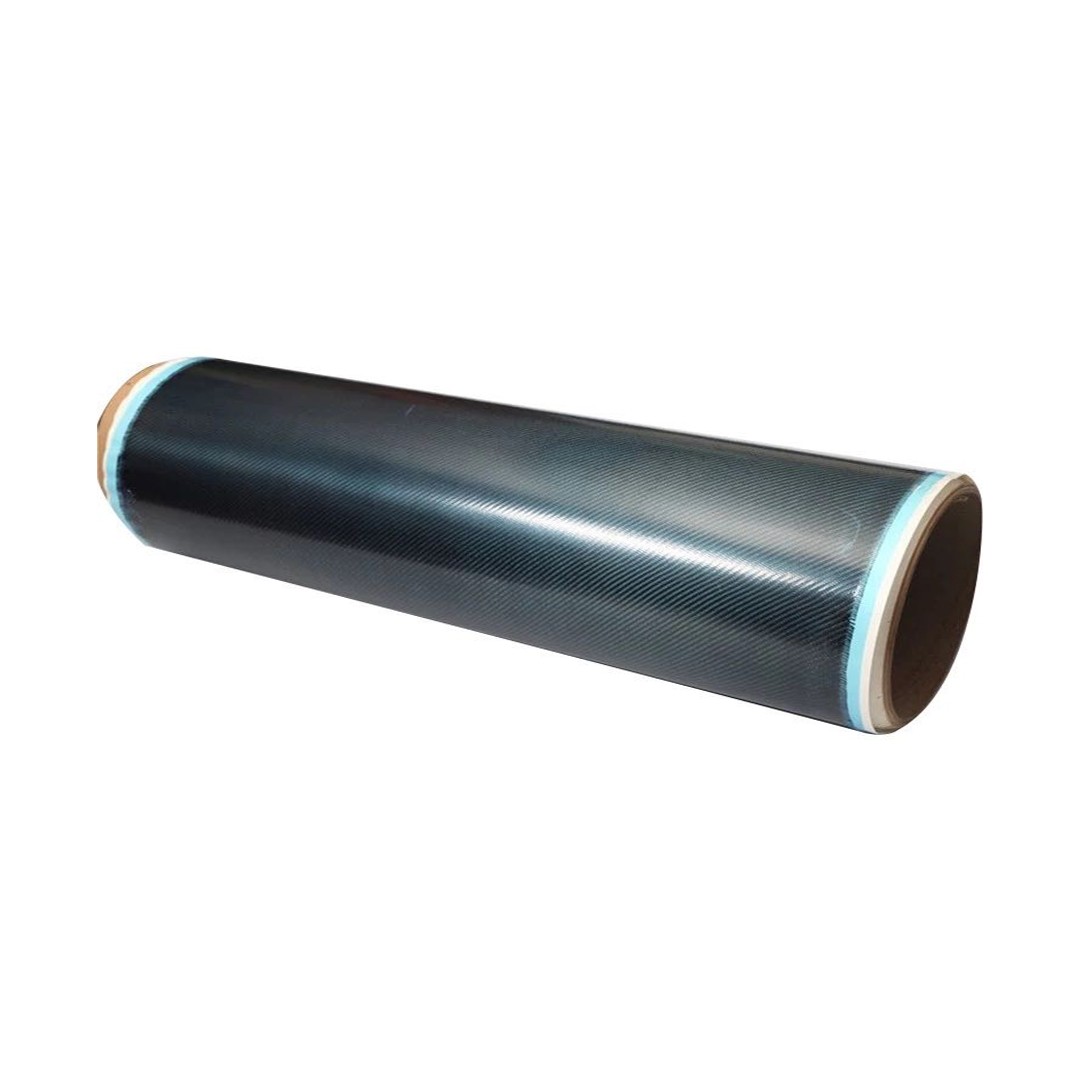

3K - 330gsm - Twill Carbon Fiber Prepreg - T300

- Code:TC-CFP-3KC200T

- Material:60% Carbon Fiber Fabric, 40% resin

- Weight:330gsm

- Function:High strengh, Low weight, Good looking, High modulus, Low thermal expansion

- Color:Black

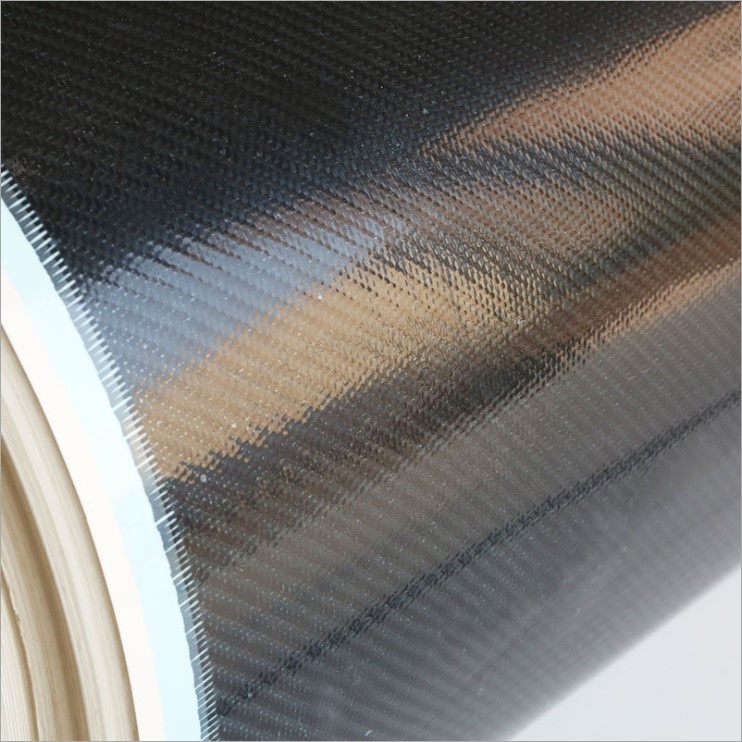

- Weave:Twill

- Width:100cm

SEND INQUIRY

Product Properties

It has strong durability and corrosion resistance, which are two commendable properties of carbon fiber reinforced cloth.

High tensile strength, low weight, carbon fiber is actually much stronger than steel in terms of strength-to-weight ratio, the weight of carbon fiber is only about one-fifth of that of steel, so that is to say, under the same weight, carbon fiber The strength is about five times that of steel.

Low thermal expansion, carbon fiber has a high resistance to temperature changes, which means that the carbon fiber gripper does not expand or contract at different temperatures. For this reason, it is ideal for factory or assembly line placement.

High modulus

Advantages of prepregs:

•Maximum strength characteristic. A typical manual ply has a lot of excess resin, which increases Brittleness and reduces overall Performance. Most prepregs contain about 35% resin, which is ideal for achieving maximum curing performance, which is usually not possible with conventional manual lamination.

•Uniformity and repeatability. The prepreg is of uniform thickness and each part coming out of the mold may theoretically be the same. Vacuum bagging technology still has some errors in processing, but prepreg can greatly reduce these problems. •Reduce curing time. After the thermal curing cycle, no need to wait for the standard 48 hours can be fully cured.

•Looks better. Although prepreg processing still requires mold preparation and demoulding, prepreg processing eliminates air bubbles and makes it easier to obtain a smooth, glossy surface.

Disadvantages of prepreg:

•High Cost. In view of the material characteristics and processing technology and other factors, the cost of prepreg is always high.

•Shelf life. HIGH-PERFORMANCE PREPREGS can be stored at room temperature (75 ° F) for up to six months, but their shelf life is shortened once they are heated and cured and stored at higher temperatures.

•Necessary Heat Cure. In order for the prepreg to cure, it must reach a minimum temperature of 270 ° F and be kept at that temperature for at least four hours, so many advanced manufacturers use autoclaves.

Material: |

60% Carbon Fiber, 40% resin | Yarn (warp): | 3k carbon fiber |

| Pattern: | Twill | Yarn (weft): | 3k carbon fiber |

| Weight : | 330gsm(carbon fabric: 200gsm) | Width: | 100cm |

| Density(warp): | 5/10cm | Thickness: | 0.28mm |

| Density(weft): | 5/10cm | Color: | Black |

Material: |

60% Carbon Fiber, 40% resin |

| Pattern: | Twill |

| Weight : | 330gsm(carbon fabric: 200gsm) |

| Density(warp): | 5/10cm |

| Density(weft): | 5/10cm |

| Yarn (warp): | 3k carbon fiber |

| Yarn (weft): | 3k carbon fiber |

| Width: | 100cm |

| Thickness: | 0.28mm |

| Color | Black |

Product Description

Carbon fiber prepreg is a combination of epoxy resin and carbon fiber under high pressure and high temperature technology. The composite material made of carbon fiber yarn, epoxy resin, release paper and other materials through coating, hot pressing, cooling, film coating, coiling and other processes is called carbon fiber prepreg, also known as carbon fiber prepreg. The reason why it is called prepreg is because this is only the initial impregnation of resin and carbon fiber, which is not the final impregnation when the product is formed.

Carbon fiber prepregs mainly include two types, one is UD carbon fiber prepreg(interior layer), one is woven carbon fiber prepreg(3k/6k plain/twill).

Carbon fiber prepreg is an intermediate material formed after carbon fiber tow is infiltrated into a resin matrix, usually a cured prepreg with a lower temperature. Prepreg will have some changes at different temperatures, the higher the temperature, the shorter the reaction curing time. In order to preserve carbon fiber prepreg for a long time, it is necessary to keep it refrigerated during transportation and storage.

Carbon fiber prepreg needs to be stored at low temperature:

At room temperature(25°C), the storage period is only 1 month,

At -5°C to 0°C, the storage period can be extended to 3 months,

At the temperature lower than -18°C , the storage period can be increased to more than 6 months.

| Content: | 60% Carbon Fiber, 40% resin |

| Specification : | 1k-12k, 205-670gsm |

| Color: | Black |

| width: | 100cm, customized width is available |

| Feature: | High tensile strength, high modulus, strong durability and corrosion resistance, low thermal expansion |

| MOQ: | 100m |

| Meet standard : | AATCC/ASTM, EN, ISO, GB, AS |

| Application : | Aerospace: fuselage, rudder, engine rocket shells, missiles diffuser, solar panels, etc. Sports equipment: auto parts, motocycle parts, fishing rod, baseball bats, skis, boats, badminton, etc. Industry: engine parts, concrete structure reinforcement materials, fan blades, drive shafts and electrical parts, carbon fiber tube, etc. |

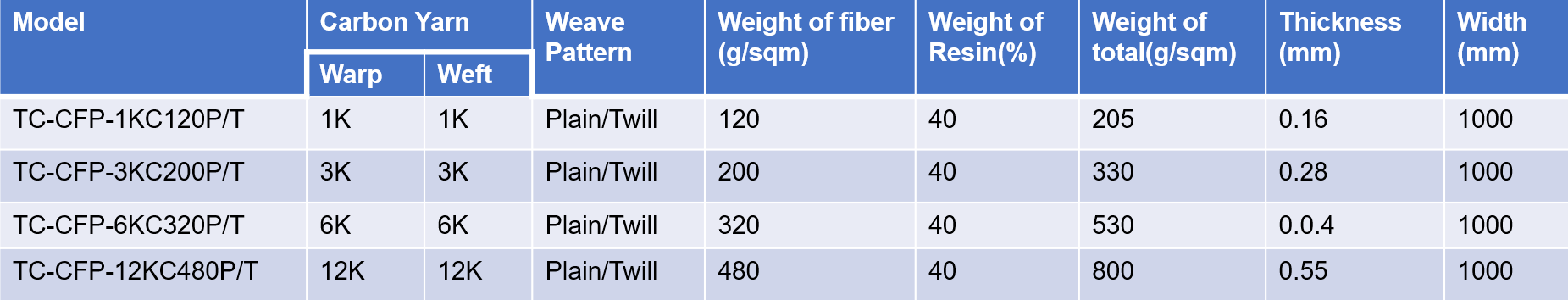

Product list of woven prepregs

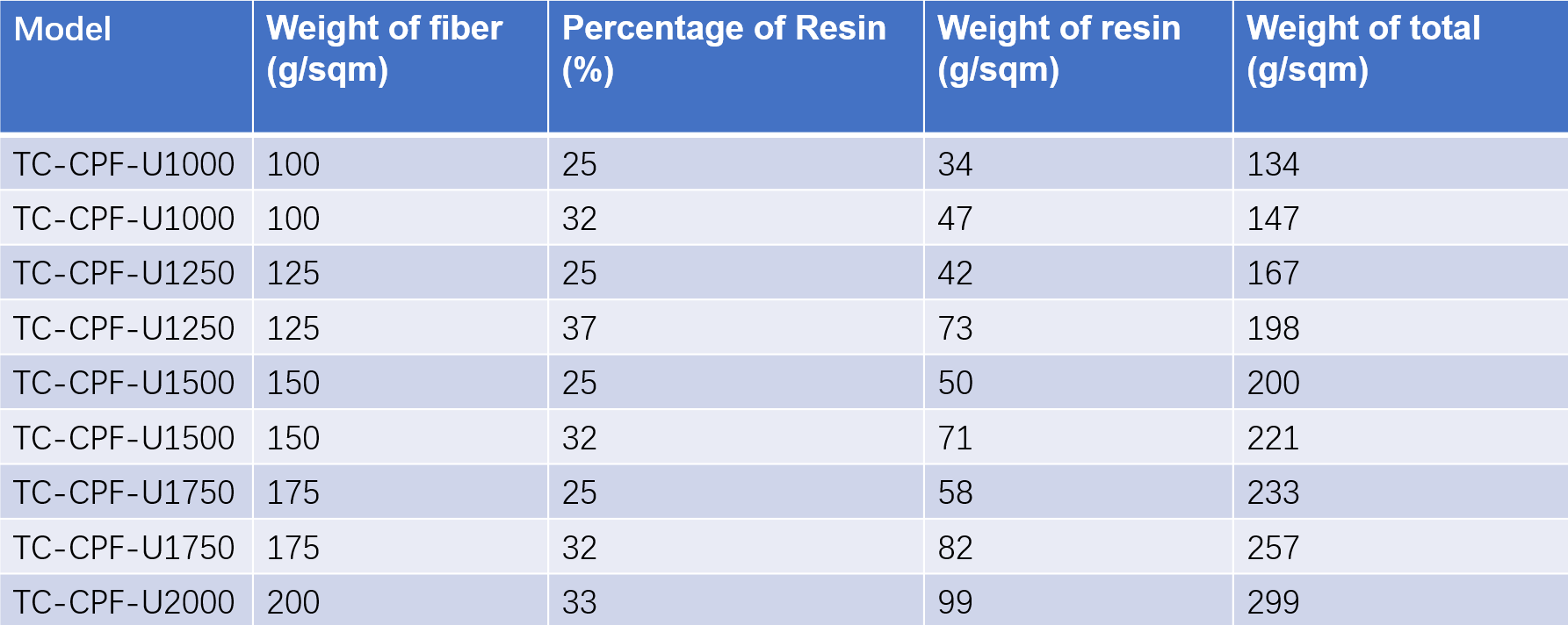

Product list of UD prepregs

SHIPPING