-

-

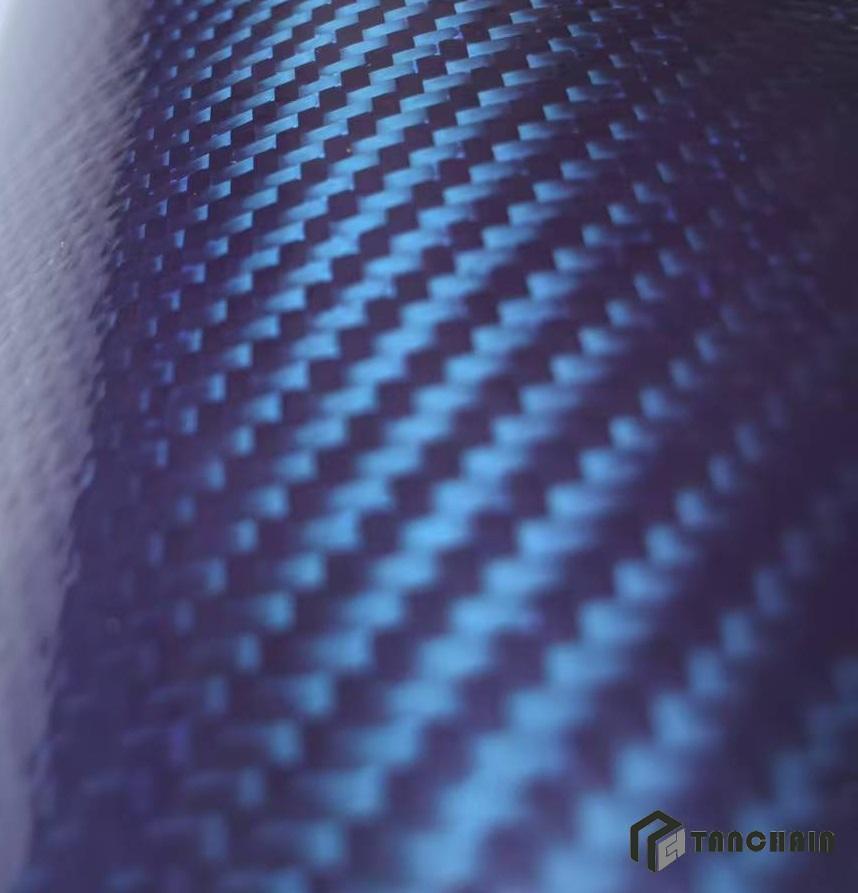

3K - 345gsm - Twill Carbon Fiber Prepreg - T300

- Code:TC-CFP-3KC200T

- Material:58% Carbon Fiber Fabric, 42% resin

- Weight:345gsm

- Function:High strengh, Low weight, Good looking, High modulus, Low thermal expansion

- Color:Black

- Weave:Twill

- Width:100cm

SEND INQUIRY

Product Properties

Twill carbon fiber prepreg is a type of carbon fiber prepreg.

Carbon fiber prepreg is an intermediate material composed of carbon fiber and resin matrix (such as epoxy resin). Twill refers to the weaving method of carbon fiber. In twill weaving, carbon fiber yarns are interwoven at a certain angle (usually greater than 0° and less than 90°) to form a diagonal grain pattern.

This weaving method makes twill carbon fiber prepreg have good mechanical properties in multiple directions. Unlike unidirectional carbon fiber prepreg, which has strong strength in only one main direction, the twill structure can withstand tension from different directions and has better shear resistance. And its surface has a unique twill texture, which can provide more beautiful visual effects in some application scenarios that require appearance, such as making high-end sports equipment (such as high-end tennis rackets) or automotive interiors.

The main uses of 345g carbon fiber prepreg (carbon fiber cloth content 58%, epoxy resin content 42%) are as follows:

Aerospace field

- Manufacturing aircraft wings, fuselages and other structural parts. Because of its high strength and low density, it can reduce the weight of the aircraft while ensuring that the structure has sufficient strength to withstand various complex stresses during flight. For example, some models of Boeing and Airbus use a large amount of carbon fiber prepreg to improve fuel efficiency.

- Used to manufacture satellite support structures and substrates for solar panels. The stability of carbon fiber prepreg helps maintain the accuracy of the structure and the performance of solar panels in the space environment.

Automotive industry

- Key components such as the body and chassis of high-performance sports cars and racing cars. For example, some super sports car brands use carbon fiber prepreg to manufacture the body, reduce the weight of the body, and improve the acceleration performance, handling performance and fuel economy of the vehicle.

- Automotive parts, such as drive shafts. Compared with traditional metal materials, the drive shaft made of carbon fiber prepreg is lighter, which can effectively reduce the unsprung mass of the vehicle and improve the driving quality.

Sports equipment

- Manufacture of advanced bicycle frames. It can make bicycles lighter, better transmit power during riding, and improve riding efficiency.

- Make golf clubs. The characteristics of carbon fiber prepreg help optimize the weight distribution and hitting performance of the club, increase the hitting distance and accuracy.

Industrial field

- Manufacturing wind turbine blades. The blades of large wind turbines need to have good strength and fatigue resistance. Carbon fiber prepreg can meet these requirements and can reduce the weight of the blades and improve power generation efficiency.

- As a structural material for industrial equipment such as robotic arms. It can provide higher rigidity and strength to ensure the stability of the robotic arm during high-precision operations.

Material: |

58% Carbon Fiber, 42% resin | Yarn (warp): | 3k carbon fiber |

| Pattern: | Twill | Yarn (weft): | 3k carbon fiber |

| Weight : | 345gsm(carbon fabric: 200gsm) | Width: | 100cm |

| Density(warp): | 5/10cm | Thickness: | 0.32mm |

| Density(weft): | 5/10cm | Color: | Black |

Material: |

58% Carbon Fiber, 42% resin |

| Pattern: | Twill |

| Weight : | 330gsm(carbon fabric: 200gsm) |

| Density(warp): | 5/10cm |

| Density(weft): | 5/10cm |

| Yarn (warp): | 3k carbon fiber |

| Yarn (weft): | 3k carbon fiber |

| Width: | 100cm |

| Thickness: | 0.32mm |

| Color | Black |

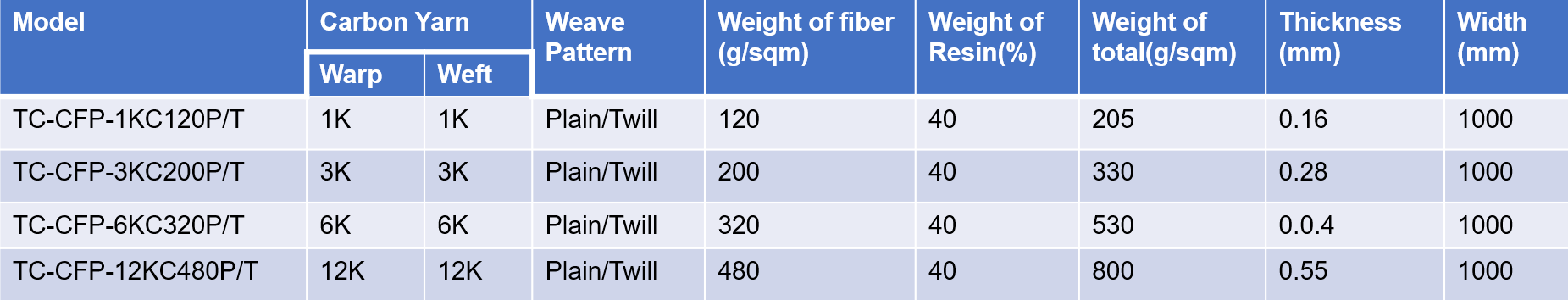

Product list of woven prepregs

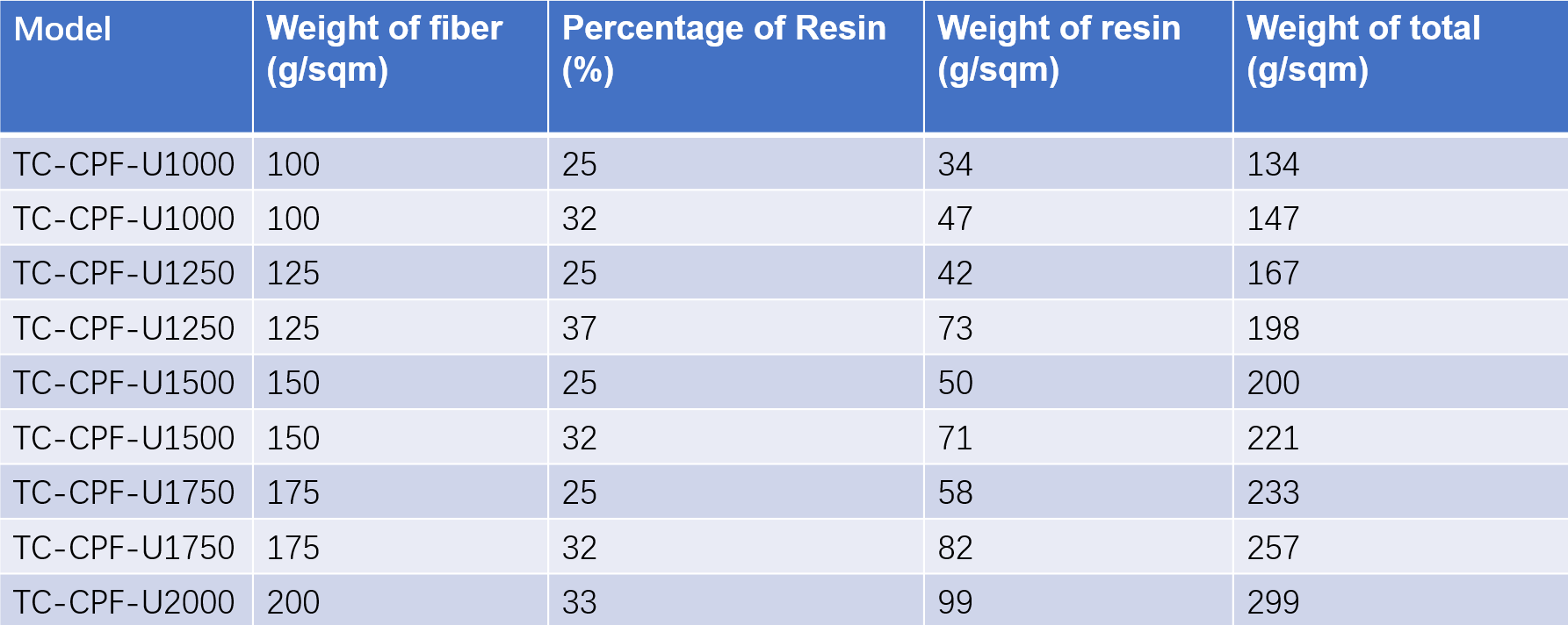

Product list of UD prepregs

SHIPPING