-

-

44gsm - Unidirectional Carbon Fiber Prepreg - T400 - carbon - fiber - 30g - Ultra-light and ultra-thin

- Code:TC-CFP-U0300

- Material:68% T400 Carbon Fiber, 32% resin

- Weight:44gsm

- Function:High strengh, Low weight, Good looking, High modulus, Low thermal expansion

- Color:Black

- Weave:Unidirectional

- Width:100cm

SEND INQUIRY

Product Properties

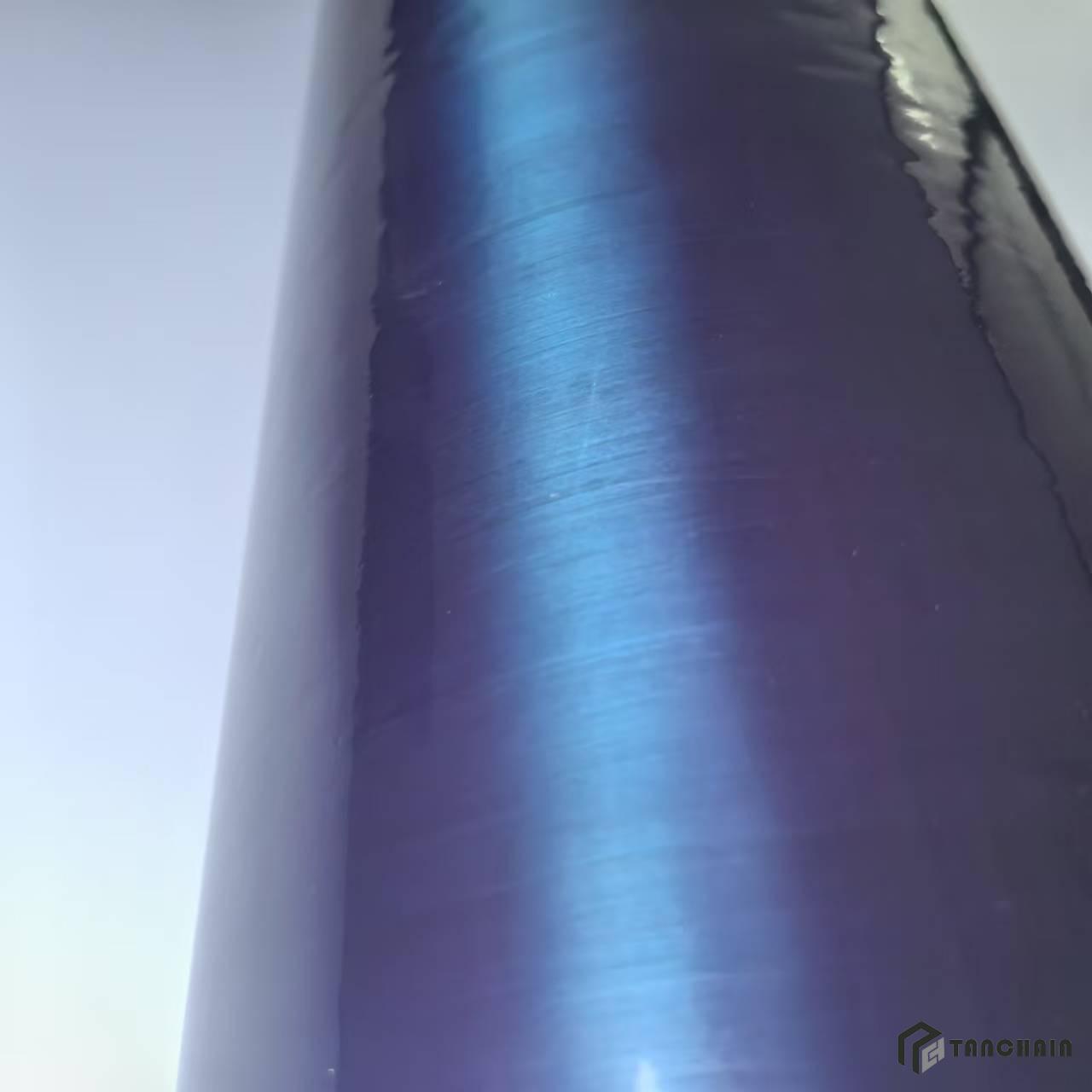

30g ultra-thin and ultra-light carbon fiber unidirectional prepreg: opening a new era of lightweight and high-performance applications

In today's era of rapid technological development, innovative achievements continue to emerge in the field of materials science, and 30g ultra-thin and ultra-light carbon fiber unidirectional prepreg is one of the shining stars. This lightweight carbon fiber prepreg, with its unique performance advantages, has shown extraordinary application potential in many fields, providing strong support for product upgrades and innovative designs.

1. Precision choice in the aerospace field

The aerospace industry has always pursued extreme lightweight and high performance to improve the efficiency, range and payload of aircraft. 30g ultra-thin and ultra-light carbon fiber unidirectional prepreg plays a key role in this field. It is widely used in the manufacture of micro-precision parts of aerospace vehicles, such as sensor brackets, micro-wing structures, and delicate components inside satellites. Its ultra-thin characteristics enable more complex and more precise structural designs to be achieved in limited space. At the same time, the ultra-light weight significantly reduces the mass of the overall structure, reduces fuel consumption, and increases payload, providing a solid guarantee for the successful execution of aerospace missions.

2. A new favorite for heat dissipation and support of high-end electronic equipment

With the rapid development of electronic technology, high-end electronic equipment such as 5G communication base station equipment and high-performance chip modules have increasingly stringent requirements for materials. 30 grams of ultra-thin and ultra-light carbon fiber unidirectional prepreg stands out for its excellent thermal conductivity and high strength-to-weight ratio. In these devices, it is used as a base material or internal support structure for heat sinks, which can efficiently conduct heat and ensure that electronic components remain in a low-temperature stable state during operation. At the same time, its high-strength characteristics effectively protect precision electronic components from external mechanical stress interference, greatly improving the reliability and service life of electronic equipment.

3. Innovation promoter in the field of medical technology

The field of medical technology has extremely high requirements for the biocompatibility, lightweight and high precision of materials, and 30 grams of ultra-thin and ultra-light carbon fiber unidirectional prepreg just meets these needs. In terms of medical devices, it is used to manufacture high-end implantable medical devices such as micro bone plates and stents. Its ultra-thin and ultra-light characteristics reduce the patient's foreign body sensation and physical burden after implantation, while the good biocompatibility of carbon fiber materials ensures the safety of long-term implantation. In addition, in medical testing equipment, such as high-precision microscope stages and micro medical sensor housings, the prepreg can provide a stable and lightweight support structure, helping medical testing technology to move towards a more accurate and efficient direction.

4. The ultimate lightweight weapon for sports competitive equipment

The field of sports competitions constantly pursues higher, faster and stronger, and the lightweight of equipment has a significant effect on improving the performance of athletes. 30 grams of ultra-thin and ultra-light carbon fiber unidirectional prepreg has been widely used in high-end sports competitive equipment. For example, in professional cycling competitions, it is used to manufacture the frames and parts of top-level bicycles, which greatly reduces the weight of the whole vehicle, allowing riders to accelerate, climb and sprint more easily; in the field of track and field running shoes, the prepreg is used in key parts of the soles and uppers, providing excellent support and light foot feel, helping athletes run faster on the field and break more records.

30 grams of ultra-thin and ultra-light carbon fiber unidirectional prepreg has shown irreplaceable importance in many high-end fields such as aerospace, electronic equipment, medical technology and sports competitions with its unique performance advantages. With the continuous advancement of technology and in-depth research and development, I believe that this innovative material will unlock more application possibilities in the future and bring more surprises and changes to the progress of human science and technology and life.

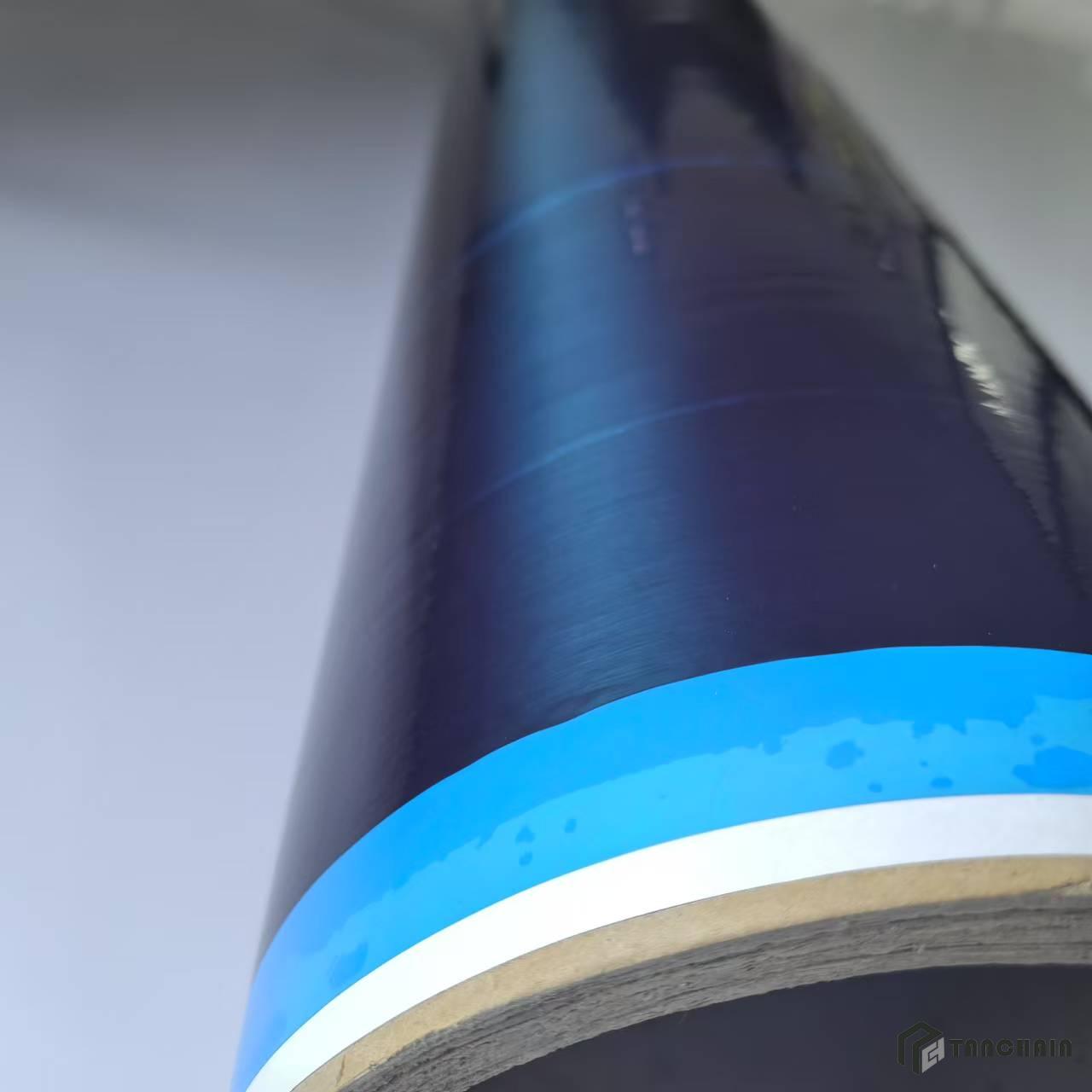

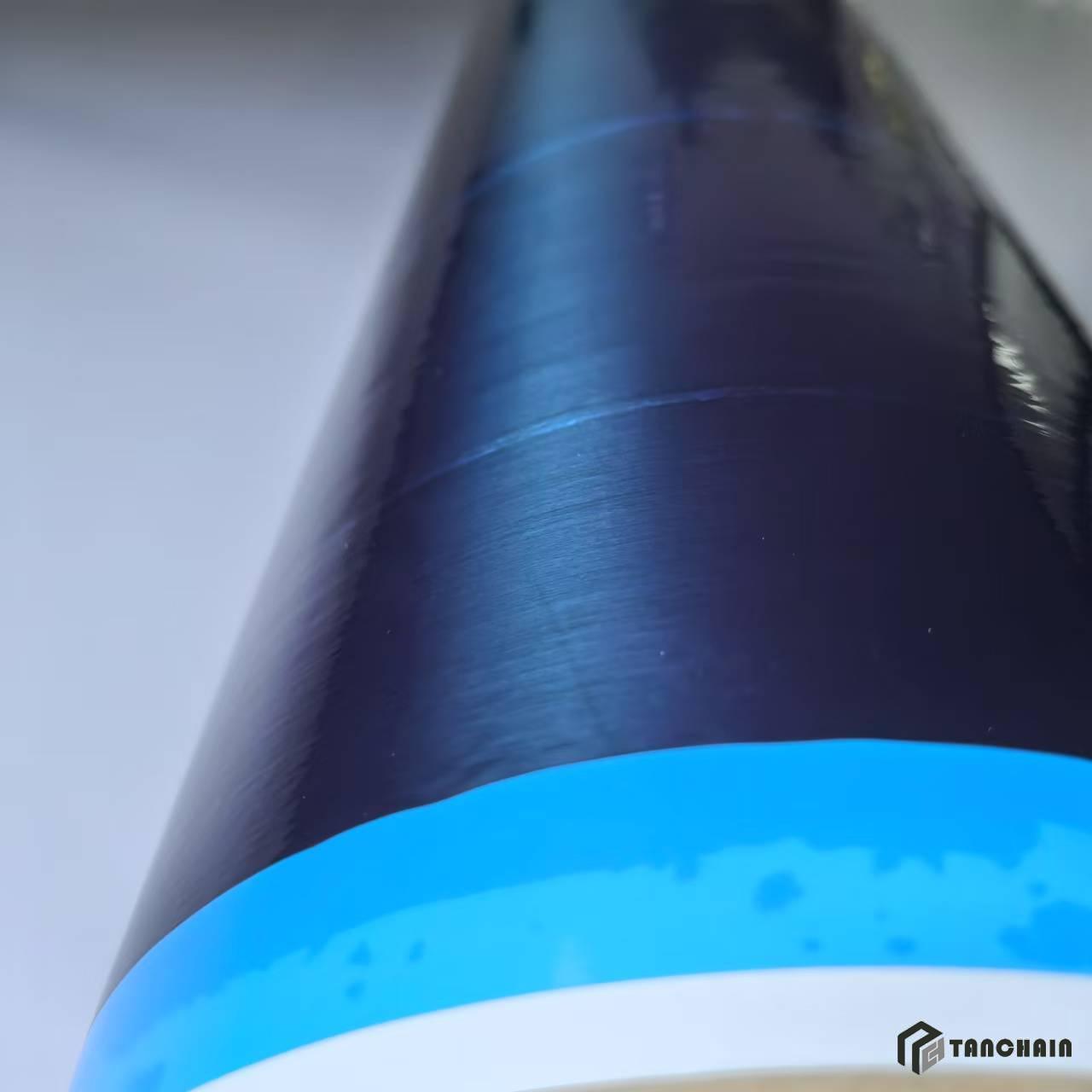

Material: |

68% Carbon Fiber, 32% resin | Yarn (warp): | 12k carbon fiber |

| Pattern: | Unidirectional | Yarn (weft): | NA |

| Weight : | 44gsm(carbon fiber: 30gsm) | Width: | 100cm |

| Color: | Black | Thickness: | 0.04mm |

Material: |

68% Carbon Fiber, 32% resin |

| Pattern: | Unidirectional |

| Weight : | 44gsm(carbon fiber: 30gsm) |

| Yarn(warp): | 12k carbon fiber |

| Yarn(weft): | NA |

| Width: | 100cm |

| Thickness: | 0.04mm |

| Color | Black |

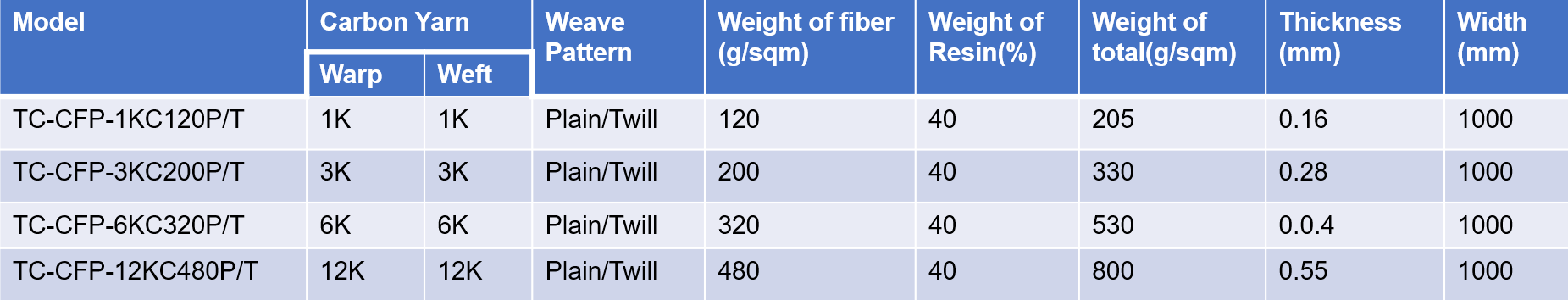

Product list of woven prepregs

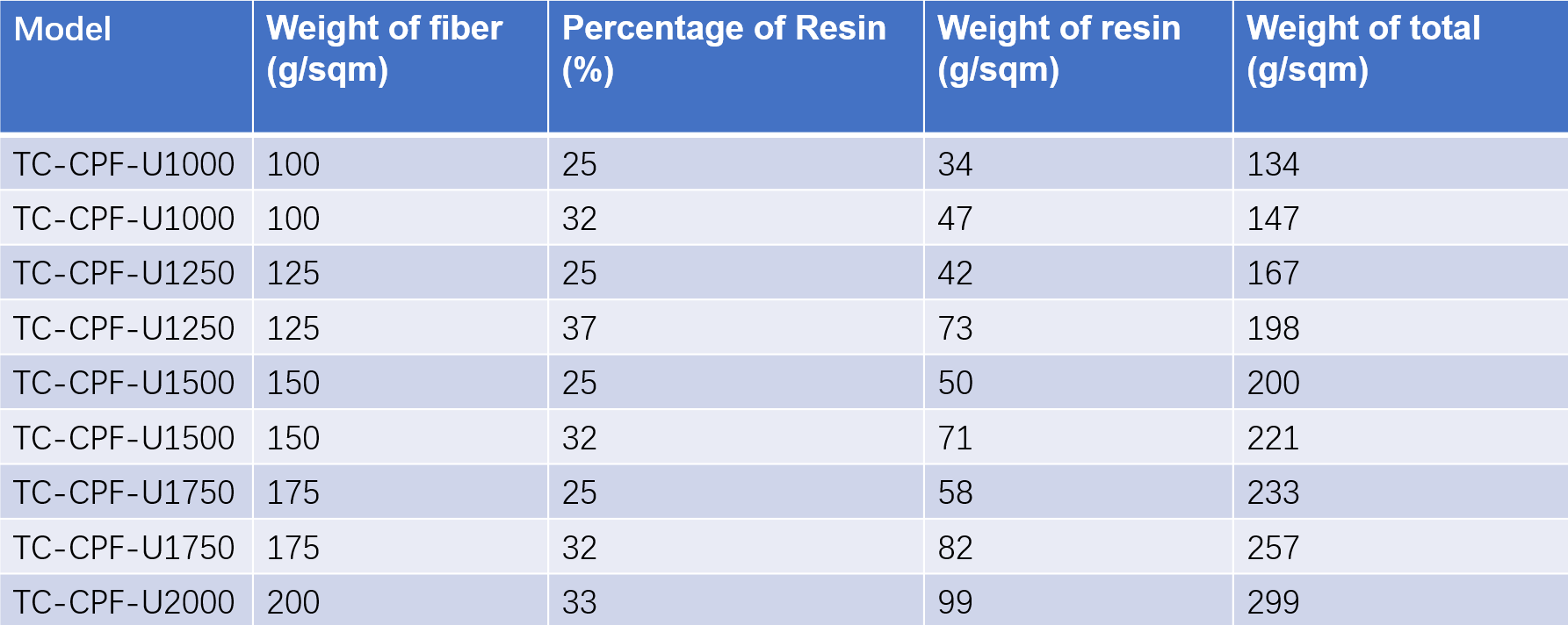

Product list of UD prepregs

SHIPPING