-

-

6K - PAN precursor of carbon fiber

- Code:TC-PAN-6K

- Material:100% Polyacrylonitrile(PAN)

- Weight:1k 3k 6k 12k 25k 35k 50k

- Function:The precusor of carbon fiber

- Color:white

SEND INQUIRY

Carbon fiber precursor is the precursor material for making carbon fiber and is an organic fiber with a high carbon content.

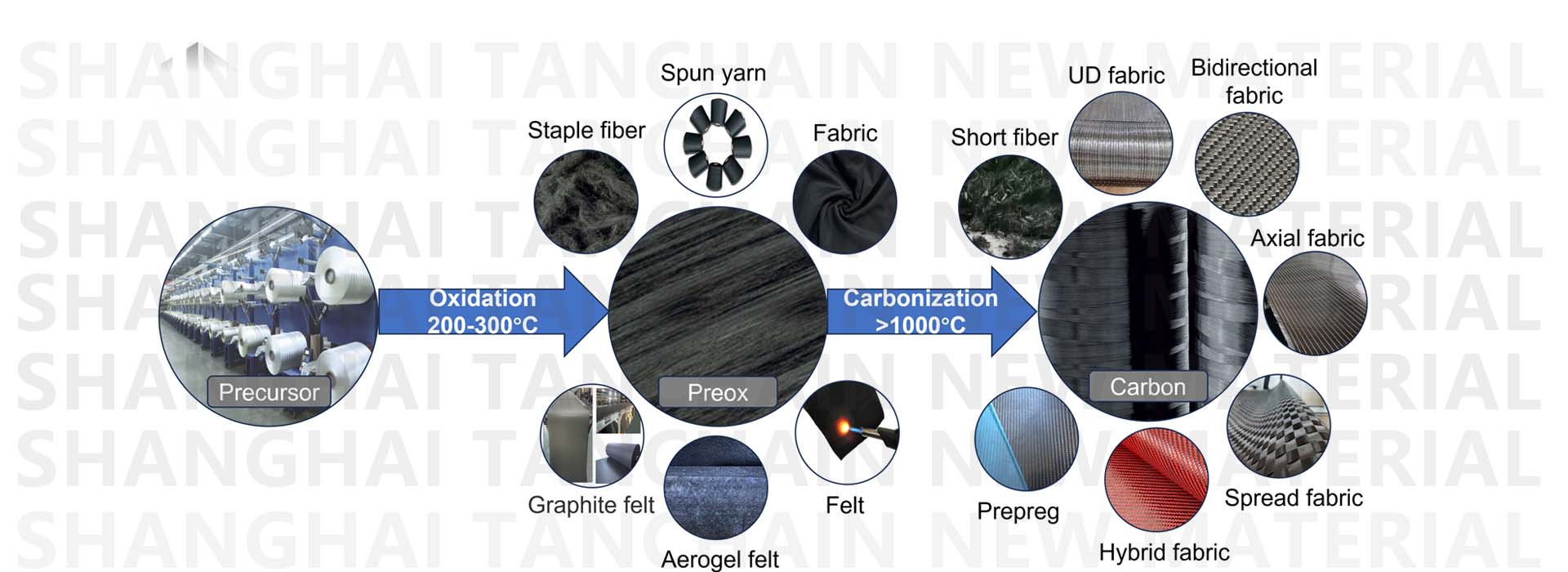

Polyacrylonitrile-based carbon fiber precursor is a type of carbon fiber precursor. It is made from polyacrylonitrile (PAN) through polymerization, spinning and other processes. This precursor has a high carbon content. After a series of complex high-temperature treatment processes such as pre-oxidation and carbonization, it can form carbon fiber with many excellent properties such as high strength, high modulus, low density, high temperature resistance, corrosion resistance, etc. It is widely used in aerospace, automotive industry, sports goods and other fields.

Compared with other types of carbon fiber precursors, polyacrylonitrile-based carbon fiber precursors have the following advantages:

- Excellent mechanical properties: It has the characteristics of high strength and high modulus. Its tensile strength and elastic modulus are outstanding among all types of carbon fiber precursors, and can meet the application scenarios with extremely high requirements for material strength and stiffness, such as the wings and fuselage structural parts of aircraft in the aerospace field.

- Relatively simple process: The production process is relatively mature and stable, easy to control and mass produce, and the product quality consistency is good, which is conducive to reducing production costs and improving production efficiency, making it more competitive in the market.

- Strong product stability: During high-temperature treatments such as pre-oxidation and carbonization, the structural changes of polyacrylonitrile-based carbon fiber precursors are relatively stable, and a regular graphite microcrystalline structure can be formed, so that it can still maintain good performance under harsh environments such as high temperature and high pressure.

- Wide range of raw material sources: The main raw material acrylonitrile can be prepared from fossil fuels such as petroleum, coal, and natural gas. The source is abundant and the supply is stable, which can meet the needs of large-scale production and is not restricted by raw material shortages.

- Good processability: It has good flexibility and weavability, and can be made into fabrics and prepregs of various shapes through textile processing, which is convenient for compounding with other materials to make final products, such as weaving into carbon fiber cloth to enhance the strength of composite materials.

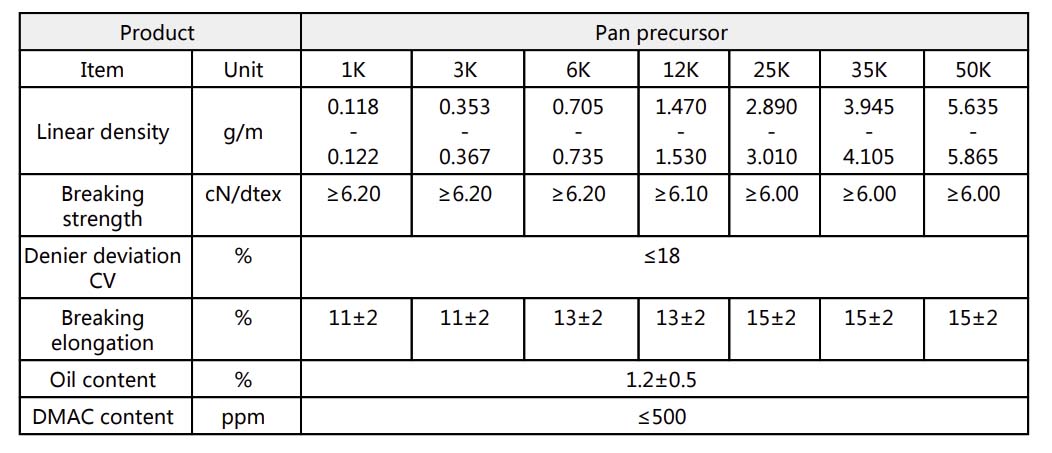

Technical Data Sheet

Tanchain's Production Flow

SHIPPING