-

-

35K - Carbon fiber filaments

- Code:TC-CF-35K

- Material:100% Carbon Fiber

- Weight:35k filaments

- Function:High strength, Low weight.

- Color:Black

SEND INQUIRY

35K carbon fiber filament is a large tow carbon fiber product with the following characteristics, uses, advantages and disadvantages, and cost-effectiveness:

- Features:

- Excellent physical properties:

- High strength: It has a very high tensile strength, which is much higher than many traditional materials, such as steel. This makes it have obvious advantages when bearing large loads and can provide sufficient strength support for the structure.

- High modulus: A high modulus means less deformation when subjected to force, which can maintain the dimensional stability and rigidity of the structure, and is suitable for application scenarios with high requirements for precision and stability.

- Low density: The density is only about one-fourth of that of steel. Its light weight makes it have important application value in fields with strict weight requirements, such as aerospace, automobiles, etc., which can effectively reduce the weight of the structure and improve the overall performance.

- Good fatigue resistance: After long-term repeated use and stress, it can still maintain good performance, is not prone to fatigue damage, and has a long service life.

- Corrosion resistance: It has good tolerance to chemicals such as acids, alkalis, and salts, and can maintain stable performance in harsh chemical environments, reducing the cost of maintenance and replacement.

- Good thermal stability: It can maintain stable performance at higher temperatures, has good heat resistance, and can be used in high temperature environments.

- Main uses:

- Aerospace field: It can be used to manufacture aircraft wings, fuselage structural parts, engine parts, etc. Its light weight and high strength characteristics can reduce the weight of the aircraft, improve fuel efficiency, increase flight mileage and load capacity.

- Automobile industry: It is used for automobile body structure, chassis parts, engine hood, etc. It can reduce the overall weight of the car, improve the fuel economy and handling performance of the car, and at the same time enhance the collision safety of the car.

- Wind power generation field: It can be used to manufacture blades, towers and other parts of wind turbines. It can withstand the effects of wind, has good wind resistance and durability, and adapts to harsh outdoor environments.

- Sports equipment field: It is used to manufacture sports goods such as golf clubs, tennis rackets, bicycles, etc. It can improve the performance and quality of sports equipment and provide athletes with a better use experience.

- Construction field: It can be used for the reinforcement and repair of building structures, such as bridges, beams and columns of buildings. It can improve the bearing capacity and seismic resistance of the structure and extend the service life of the building.

- Advantages and Disadvantages:

- Advantages:

- Outstanding performance: As mentioned above, the high strength, high modulus, fatigue resistance, corrosion resistance, good thermal stability and other characteristics make it have irreplaceable advantages in many fields.

- High design flexibility: It can be processed and formed according to different application requirements, such as weaving, winding, injection molding, etc., and can meet the design requirements of various complex structures.

- Energy saving and emission reduction: Application in the fields of automobiles, aviation, etc. can reduce energy consumption and emissions, which meets the requirements of modern society for energy saving and emission reduction.

- Disadvantages:

- Difficult processing: The processing process of carbon fiber filaments requires special equipment and processes, and has high requirements for processing technology. The processing is difficult, which increases the production cost and production cycle.

- Poor impact resistance: Carbon fiber materials are relatively brittle and have relatively weak impact resistance. They are prone to breakage or damage when subjected to large impact forces.

- High price: Although the price of carbon fiber is gradually decreasing with the continuous advancement of production technology, it is still relatively high at present, which limits its wide application in some cost-sensitive fields.

- Cost-effectiveness:

- From the performance point of view: the high performance of 35K carbon fiber filament makes it highly cost-effective in fields with extremely high requirements for material performance. For example, in the field of aerospace, although the price of carbon fiber is relatively high, it can significantly reduce the weight of the aircraft, improve fuel efficiency and flight performance. From the perspective of the entire aircraft life cycle, the use of carbon fiber has a high cost-effectiveness.

- Compared with other materials: Compared with traditional metal materials such as steel, carbon fiber has obvious advantages in weight, strength, corrosion resistance, etc. In some application scenarios with high requirements for weight and performance, the use of carbon fiber can replace some metal materials. Although the initial investment may be high, it can reduce maintenance costs and replacement costs in the long run, and has a good cost-effectiveness.

- Consider the scale of application: With the continuous improvement of carbon fiber production technology and the expansion of production capacity, its price has gradually decreased. In the case of large-scale application, the cost-effectiveness will be further improved. For example, in the automotive industry and wind power generation, as the application scale of carbon fiber continues to expand, its cost will gradually decrease, and the cost-effectiveness will also increase accordingly.

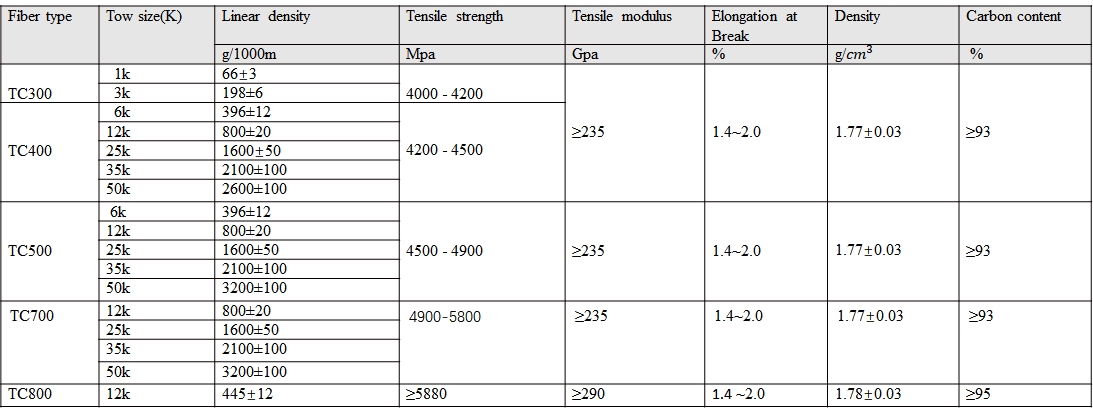

Technical Data

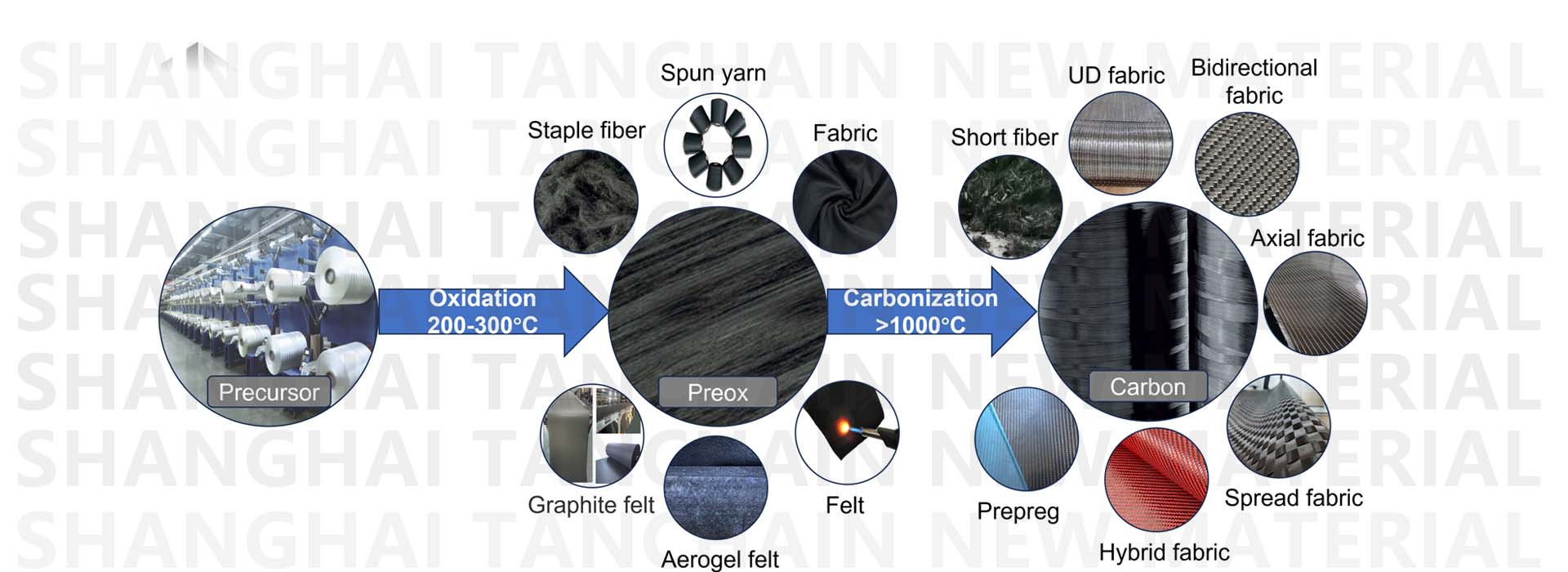

Production Line

Tanchain's Production Flow

SHIPPING