-

-

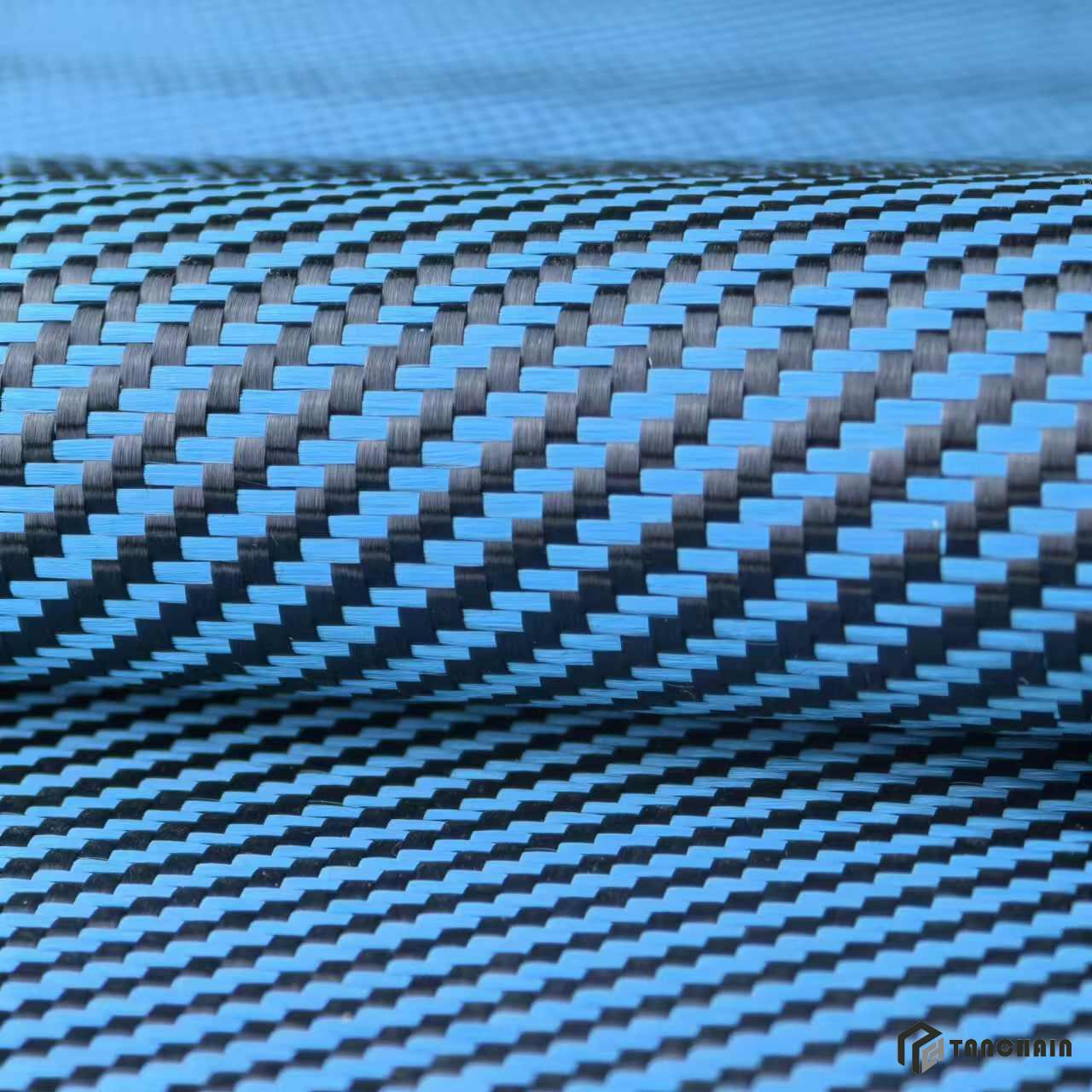

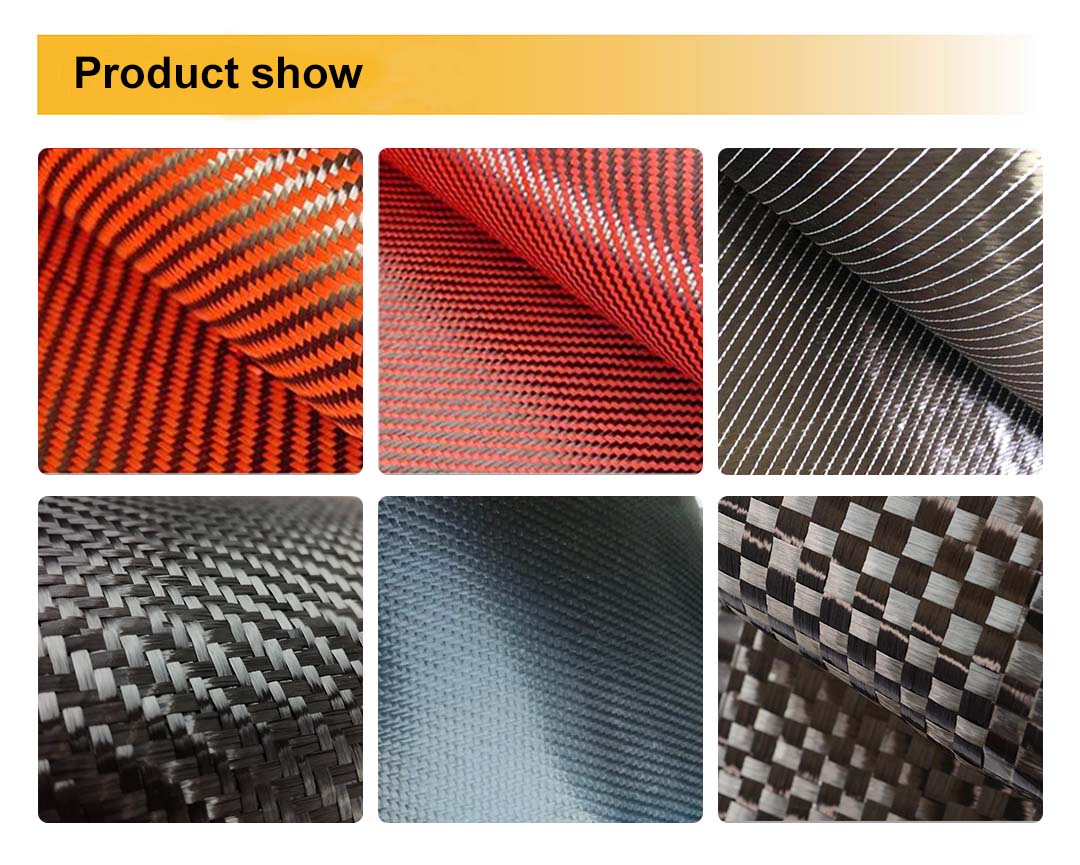

3K - 260gsm - Twill - carbon fiber/Kevlar hybrid fabric

- Code:TC-CKL-C260T

- Material:50% Carbon fiber, 50% Kevlar

- Weight:260gsm

- Function:High Temperature Resistant, High Strength, Flame Retardant, Fire Retardant, Waterproof, Anti-Static

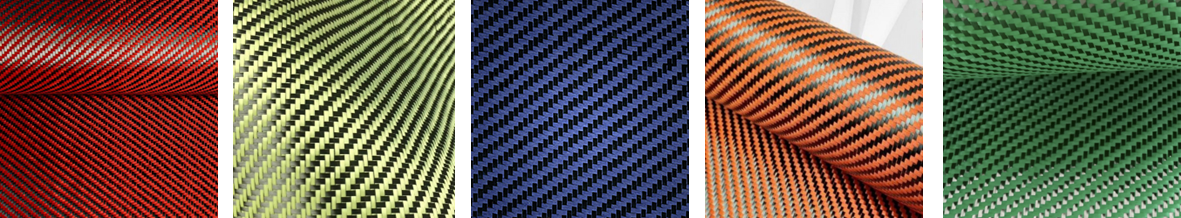

- Color:Lake blue

- Weave:Twill

- Width:50~150CM

SEND INQUIRY

Material: |

50% para aramid, kevlar, 50% carbon fiber | Yarn Count(warp): | 3k carbon fiber |

| Pattern: | Twill | Yarn Count(weft): | 1500D kevlar |

| Weight : | 260gsm | Width: | 50-150cm |

| Density(warp): | 7/10cm | Thickness: | 0.40mm |

| Density(weft): | 7/10cm | Color: | Lake blue |

Material: |

50% para aramid, kevlar, 50% carbon fiber |

| Pattern: | Twill |

| Weight : | 260gsm |

| Density(warp): | 7/10cm |

| Density(weft): | 7/10cm |

| Yarn Count(warp): | 3k carbon fiber |

| Yarn Count(weft): | 1500D kevlar |

| Width: | 50-150cm |

| Thickness: | 0.40mm |

| Color | Lake blue |

Product Description

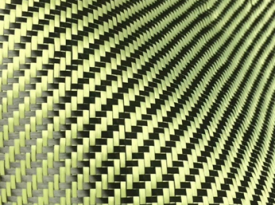

260g Lake Blue Aramid Carbon Fiber Blended Fabric has a variety of unique properties and has a wide range of application scenarios in multiple fields:

Performance characteristics:

- High strength: Carbon fiber itself has very high strength, which is much higher than ordinary fiber materials. Aramid fiber is also a high-strength fiber. After the two are blended, the overall strength of the fabric is further improved, and it can withstand greater tension and pressure, which has advantages in some occasions where high material strength is required.

- High toughness: Aramid fiber has good toughness and impact resistance. After blending with carbon fiber, it can effectively improve the brittleness of carbon fiber, making the fabric less likely to break when impacted by external forces, and has better toughness and impact resistance.

- High temperature resistance: Aramid fiber can be used for a long time at a high temperature of 220℃ without aging, and has good heat resistance. Carbon fiber also has high high temperature resistance, so the blended fabric can maintain good performance stability in high temperature environments and is suitable for some high temperature working environments.

- Lightweight: The density of carbon fiber and aramid fiber is relatively small, and the mixed fabric is light, which is of great significance for some application scenarios with strict weight requirements, such as aerospace, high-performance sports equipment, etc.

- Good dimensional stability: Aramid fiber has excellent dimensional stability. After being mixed with carbon fiber, the dimensional stability of the fabric is further improved. It is not easy to deform during use and can maintain good dimensional accuracy.

- Corrosion resistance: Both fiber materials have good corrosion resistance. The mixed fabric can be used for a long time in corrosive environments such as acids and alkalis, and is suitable for some fields that require high corrosion resistance of materials.

- Good wear resistance: Aramid fiber has high wear resistance, and carbon fiber also has good wear resistance. The mixed fabric can withstand friction and wear during use and has a long service life.

- Insulation: Aramid fiber is an insulating material. After being mixed with carbon fiber, the fabric still has good insulation performance to a certain extent, which is suitable for some occasions that require insulation performance.

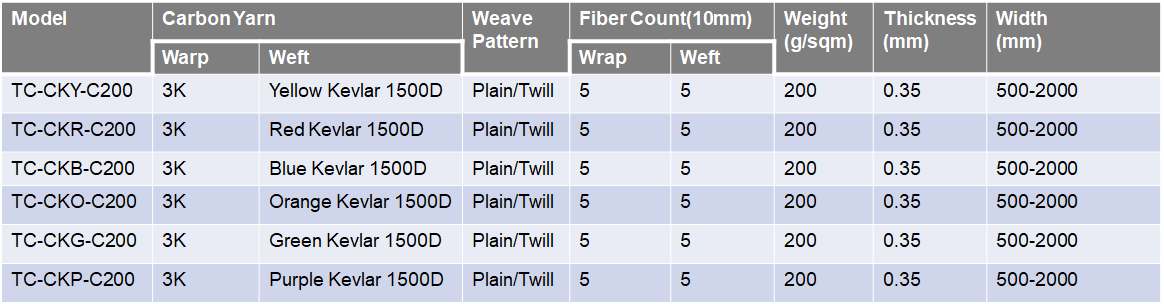

Similar Series Technical Data

APPLICATIONS

SHIPPING