-

-

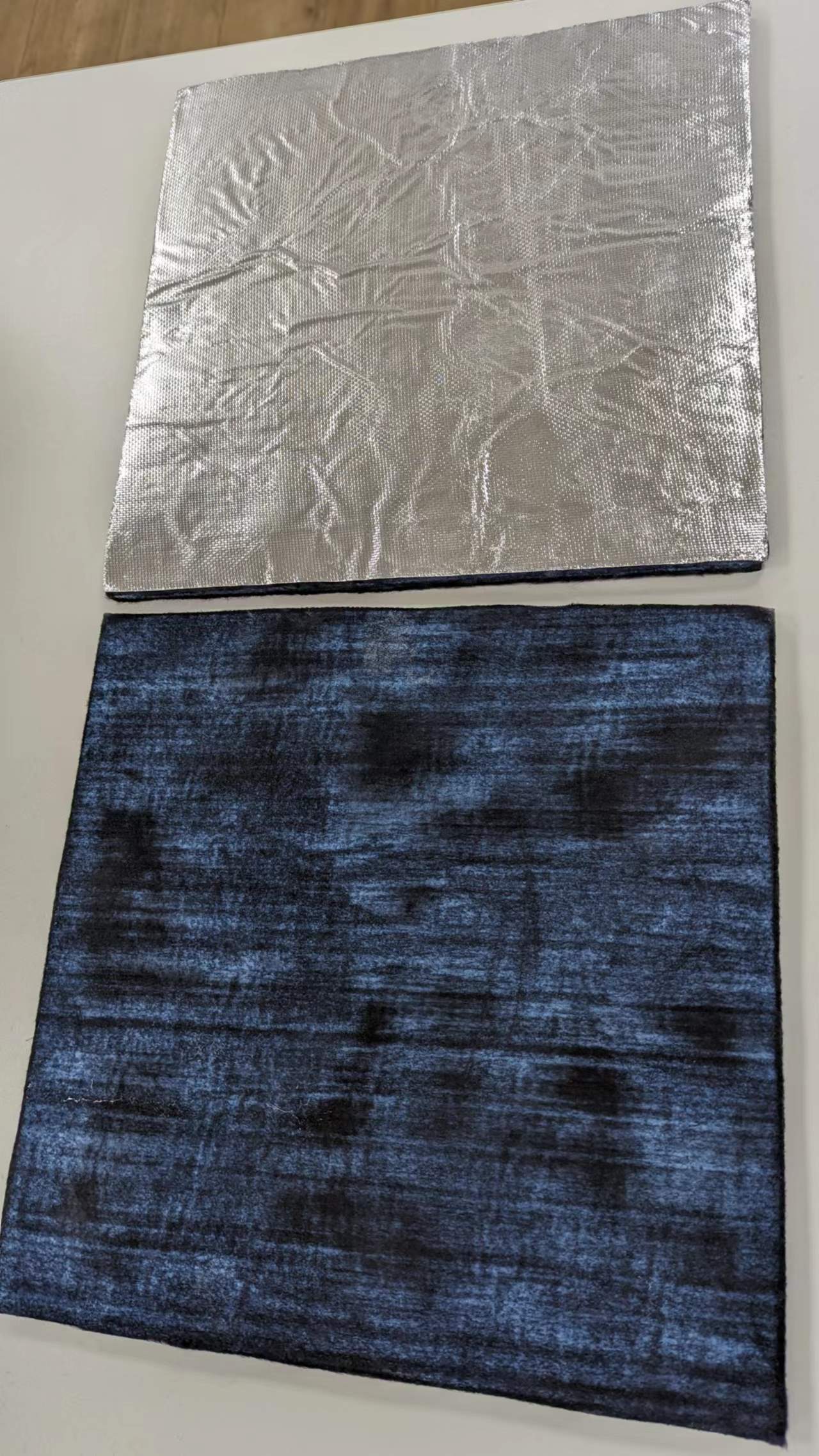

Silica aerogel impregnated OX felt - Very low thermal conductivity - Long-term 650℃

- Code: TG-OPF-003

- Material:Silica aerogel impregnated OX

- Weight:400gsm

- Function:Flame Retardant, Heat insulation, Thinner insulation thickness, Very low thermal conductivity

SEND INQUIRY

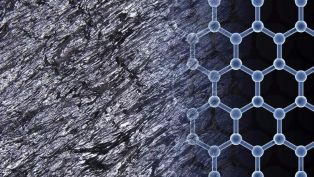

What is Aerogel insulation felt

Aerogel insulation felt is a flexible felt made of SiO₂ aerogel and various fibers (glass fiber, polyester fiber, pre-oxygen fiber), and adopts the process of sol-gel in-situ compounding. Aerogel insulation felt has a wide range of applicable temperatures (by compounding with different substrates), from -200°C low temperature to 650°C high temperature.

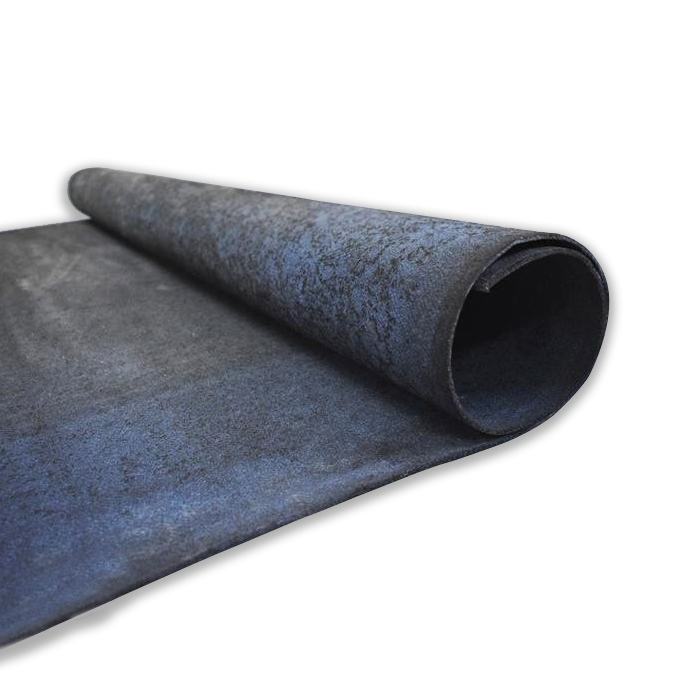

What is Silica aerogel impregnated OX insulation felt

Silica aerogel impregnated OX insulation felt is reinforced aerogel felt by OPAN fiber, it is composed of oxidized fiber and silica aerogel. It’s a new thermal insulation product that has outstanding heat and flame resistance.

OPAN fiber is a chemically resistant fiber having high temperature resistance. The density of oxidized fiber is lower than glass and ceramic fibers and it’s much easier to process, without causing generation of broken filaments.

-

Silica aerogels have high porosity (80-99.8%) with typical pore sizes between 1 - 100nm. Its specific surface area is (200-1000m²/g) and bulk density can be as low as 3 kg/m³. Silica aerogels have outstanding insulation properties and are known to have the lowest thermal conductivity of all solid materials.

Thick silica aerogel, 10mm.

The excellent properties of Silica aerogel impregnated OX insulation felt

Exceptionally Low Thermal Conductivity: 0.020 W/(m·K), at room temperature, Its insulation performance is 3-5 times better than traditional thermal insulation materials.

Fire Resistant and Hydrophobic: Achieves the national class A non-combustible standard for building materials and it has a water repellency rate ≥99%.

Lightweight and High Strength: The product has a bulk density of ~200kg/m³, good flexibility and tensile strength.

Weather Resistance: These aerogel insulation barriers do not easily disintegrate or change over time. Its service life can reach more than 10 years, 3-5 times longer than traditional insulation materials.

Easily Processed: This product is easily die cut with conventional cutting tools into desired shapes suitable for complex parts.

Safe and Corrosion Resistant: The product effectively prevents penetration of liquid water and inhibits corrosion of items protected by the insulation layer.

Health and Environmentally Friendly: The product passed RoHS test standards and does not contain substances harmful to the humans.

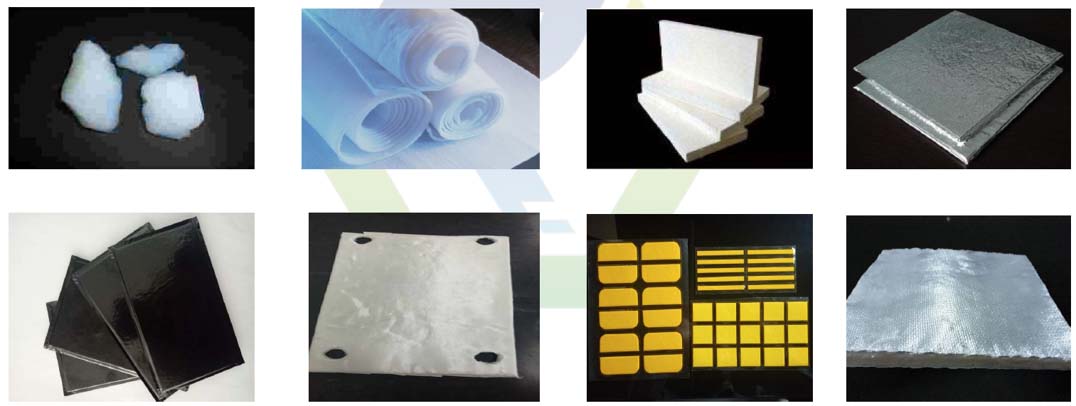

Silica aerogel impregnated OX insulation products

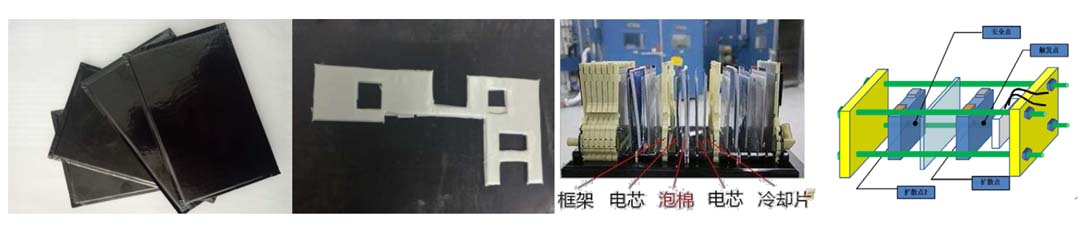

Needled felts are specially processed with silica aerogels and then encapsulated with polyimide or other thermoplastic films, glass fiber cloth, aluminum foil or other materials, according to each end use requirements.

-

Customized shapes and thicknesses, according to the end use, can be tailor made for petroleum and petrochemical thermal insulation, new energy battery insulation barriers, electrical and electronic insulation, industrial equipment insulation and in other insulation markets.

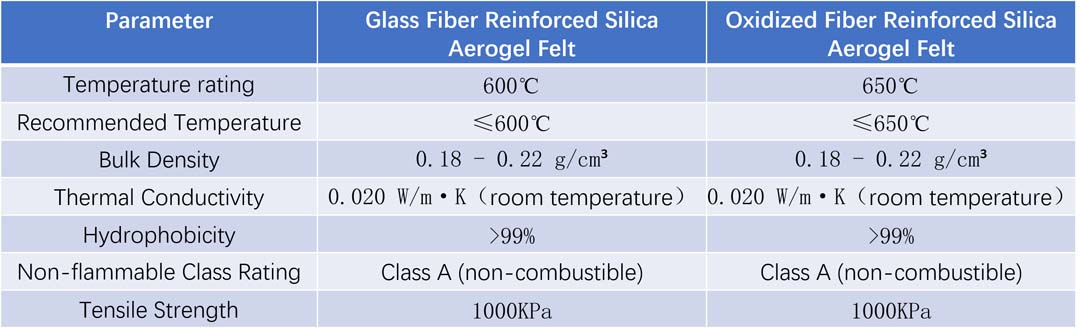

The excellent parameters of Silica aerogel impregnated OX insulation felt

Composite aerogel insulation materials are prepared by processing oxidized felt with an impregnating aerogel sol, followed by solvent replacement and supercritical drying. The final composite product has low thermal conductivity, good flexibility, high tensile strength and inherent flame and heat resistance.

The broad application range of Silica aerogel impregnated OX insulation felt

1. General Automotive – Heat Insulation:

Low Thermal Conductivity: To ensure that the heat insulation part is maintained at low temperature and peak performance

Fire Performance: A1 class non-combustible, effective fire prevention

Thickness & Weight: Occupies less space, is very lightweight.

2. Electric Vehicles – Passenger Compartment Fire Protection:

Oxidized Fiber based Aerogel Insulation is applied between the floor and passenger compartment to provide both fire protection and heat insulation.

In a test using a flame gun against a 5mm thick oxidized fiber-based aerogel felt: The backside of the insulation material maintained <170⁰C, after a burn time of >10minutes.

This excellent heat insulation and fire resistance allows the necessary time for passengers to escape, in case of fire.

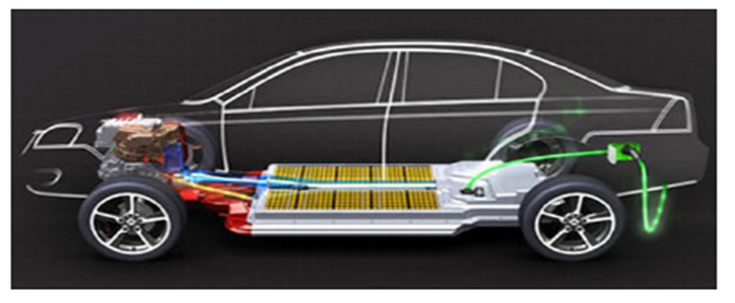

3. Electric Vehicles – Battery Cell Runaway Thermal Barriers:

Thermal Barriers between the battery cells within a battery pack are required to ensure stable operation of the battery, at low temperature, and reduce the probability of a fire accident in the case of a thermal runaway event within the battery pack.

Oxidized felt reinforced aerogel is the ideal choice to ensure the safety of new energy vehicle batteries.

4. Other applications

Defense missile, rocket, aircraft engine heat insulation materials, heat insulation and weight reduction.

Industrial equipment & furnace insulation, heat & chemical pipeline insulation, household appliances, transportation, cold chain logistics, construction and other types of heat insulation.