-

-

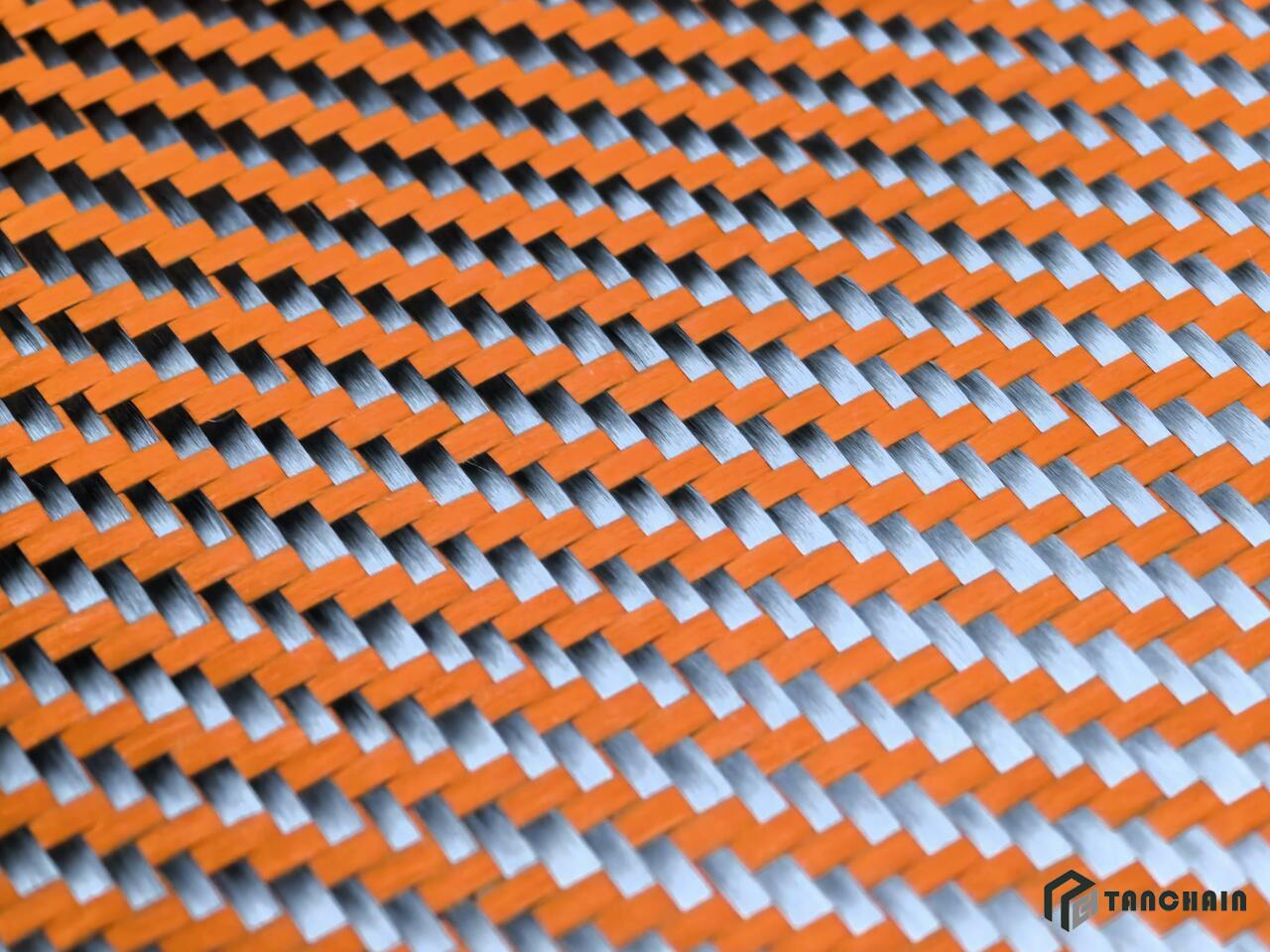

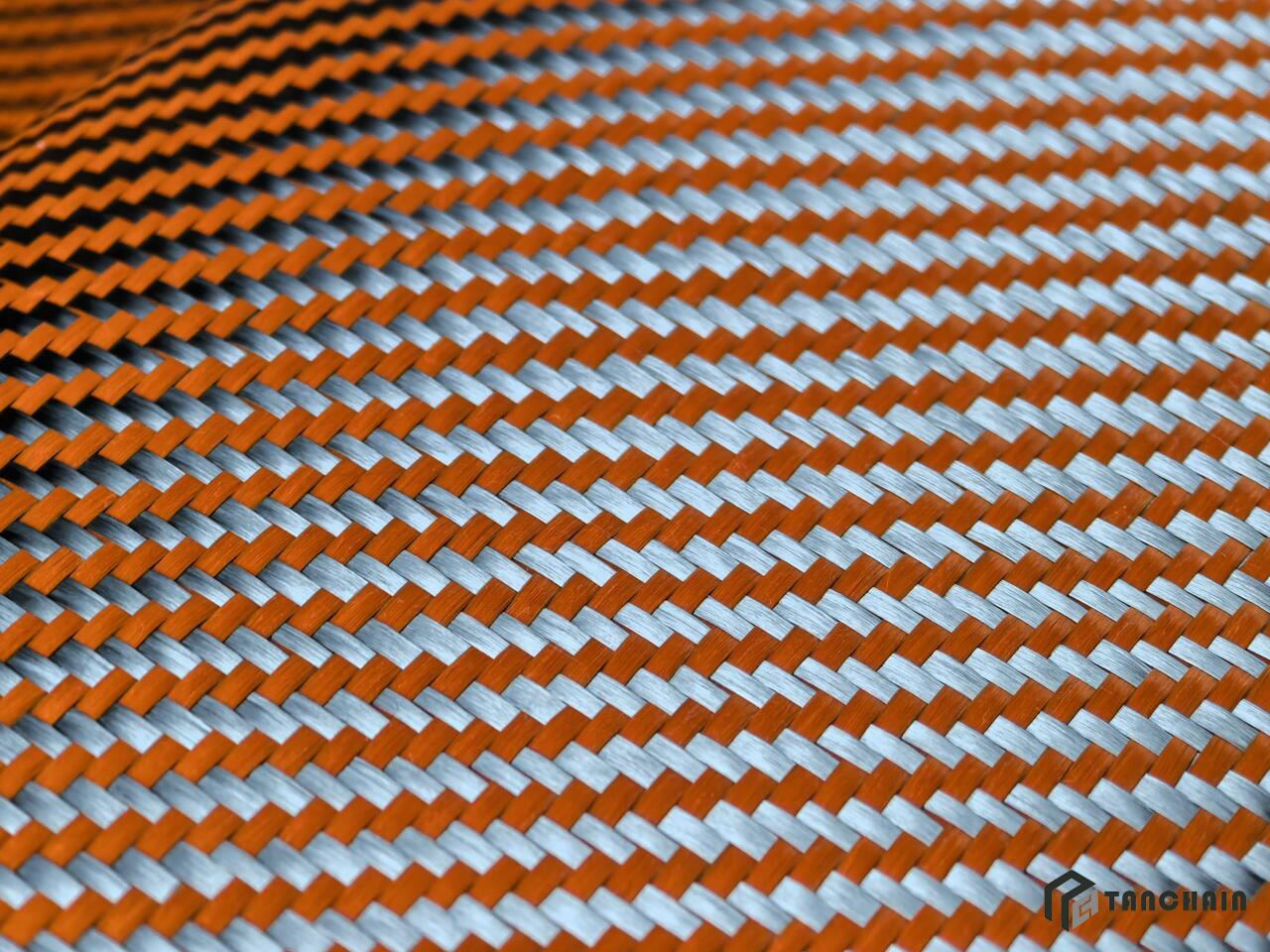

3K - 200gsm - Twill - carbon fiber/Orange Kevlar hybrid fabric

- Code:TC-CKO-C200T

- Material:50% Carbon fiber, 50% Kevlar

- Weight:200gsm

- Function:Good appearance, Orange color, High strength

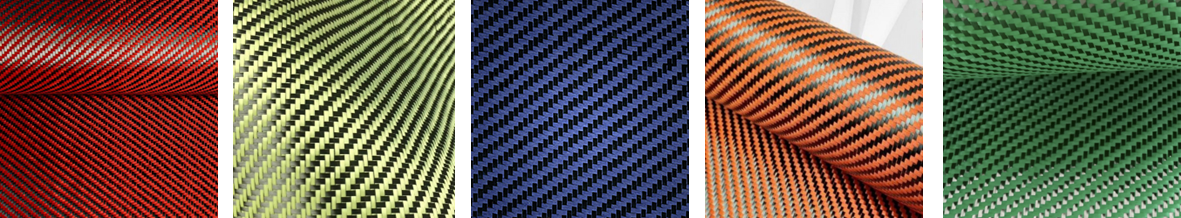

- Color:Black and Orange interweaving

- Weave:Twill

- Width:50~150CM

SEND INQUIRY

Material: |

50% para aramid, kevlar, 50% carbon fiber | Yarn Count(warp): | 3k carbon fiber |

| Pattern: | Twill | Yarn Count(weft): | 1500D kevlar |

| Weight : | 200gsm | Width: | 50-150cm |

| Density(warp): | 5/10cm | Thickness: | 0.35mm |

| Density(weft): | 5/10cm | Color: | Black and Orange interweaving |

Material: |

50% para aramid, kevlar, 50% carbon fiber |

| Pattern: | Twill |

| Weight : | 200gsm |

| Density(warp): | 5/10cm |

| Density(weft): | 5/10cm |

| Yarn Count(warp): | 3k carbon fiber |

| Yarn Count(weft): | 1500D kevlar |

| Width: | 50-150cm |

| Thickness: | 0.35mm |

| Color | Black and Yellow, Red, Blue, Orange interweaving |

Product Description

Appearance characteristics

- 3K carbon fiber: 3K carbon fiber usually has obvious filamentary texture, and the fiber is relatively fine. Regular carbon fiber texture is presented on the surface of the fabric, and the color is generally dark and bright, with a certain glossiness and strong texture.

- 1500D Kevlar: Kevlar fiber is usually yellow, black, blue, red, green, orange, gold, etc. 1500D indicates its denier number, and the fiber is relatively coarse. After mixing with carbon fiber, the overall appearance of the fabric will be slightly rough and have a certain graininess due to the presence of Kevlar fiber while maintaining the carbon fiber texture. Twill weave will make the surface of the fabric have oblique texture, which increases the visual level.

Performance characteristics

- Strength and toughness: Carbon fiber itself has high strength and high modulus. 3K carbon fiber can provide good tensile resistance in this mixed fabric. Kevlar fiber has super high strength and toughness, especially excellent impact resistance. After the two fibers are mixed, the comprehensive strength and toughness of the fabric are improved, and it can withstand greater external forces without being easily damaged.

- Wear resistance: The addition of Kevlar fiber greatly enhances the wear resistance of the fabric, can resist friction and scratches, and extend the service life of the fabric.

- Heat resistance: Carbon fiber has good heat resistance, and Kevlar fiber can also withstand high temperatures to a certain extent. The mixed fabric has good thermal stability and can maintain certain performance in high temperature environments.

Application areas

Carbon fiber is usually black in color and has a shiny texture; colored aramid can have a variety of colors, such as yellow, black, blue, red, green, orange, gold, etc. The mixed appearance of the two is very distinctive.

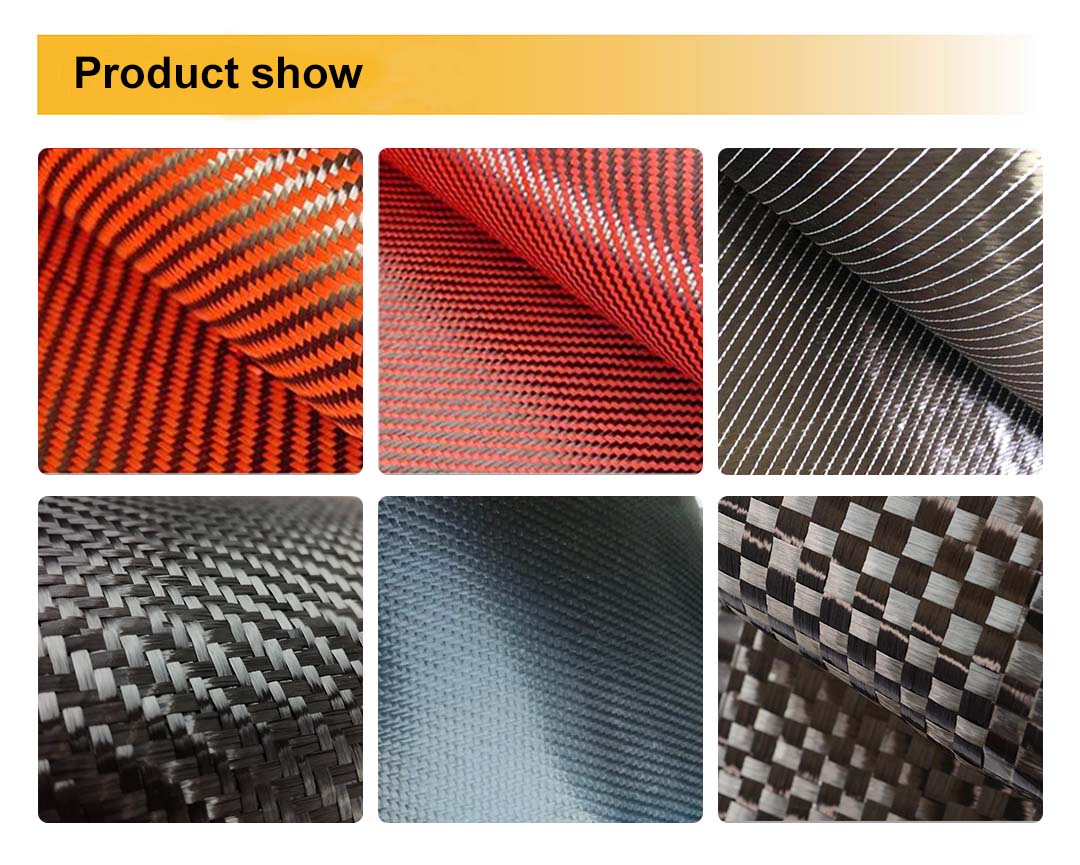

In the fashion field, this mixed fabric can be used to make high-end clothing, such as trendy sports jackets, backpacks, etc. Its unique fiber interwoven appearance combines the gloss of carbon fiber and the rich colors of colored aramid to form a cool visual effect.

In terms of automotive interiors, it can be used for seats, steering wheel covers and other parts. The combination of black carbon fiber and colored aramid can add lively color elements while showing the technological sense of the automotive interior, enhancing the overall aesthetics of the interior.

In the field of decorative materials, such as wall decorative panels, mixed fabrics can create a modern and industrial decorative style with their special appearance.

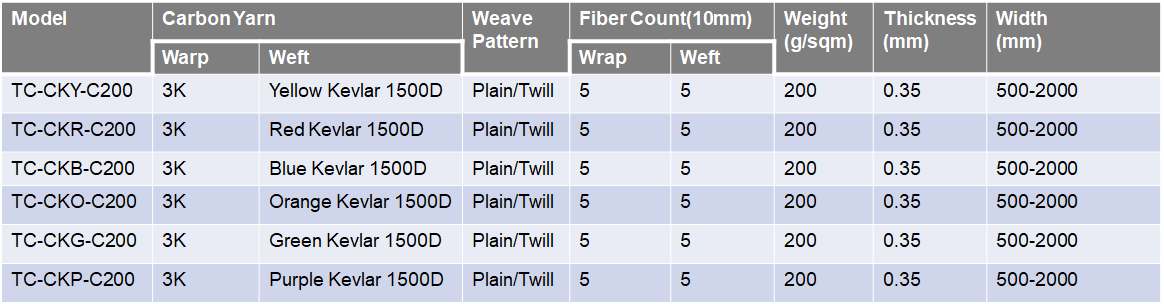

Similar Series Technical Data

APPLICATIONS

SHIPPING