-

-

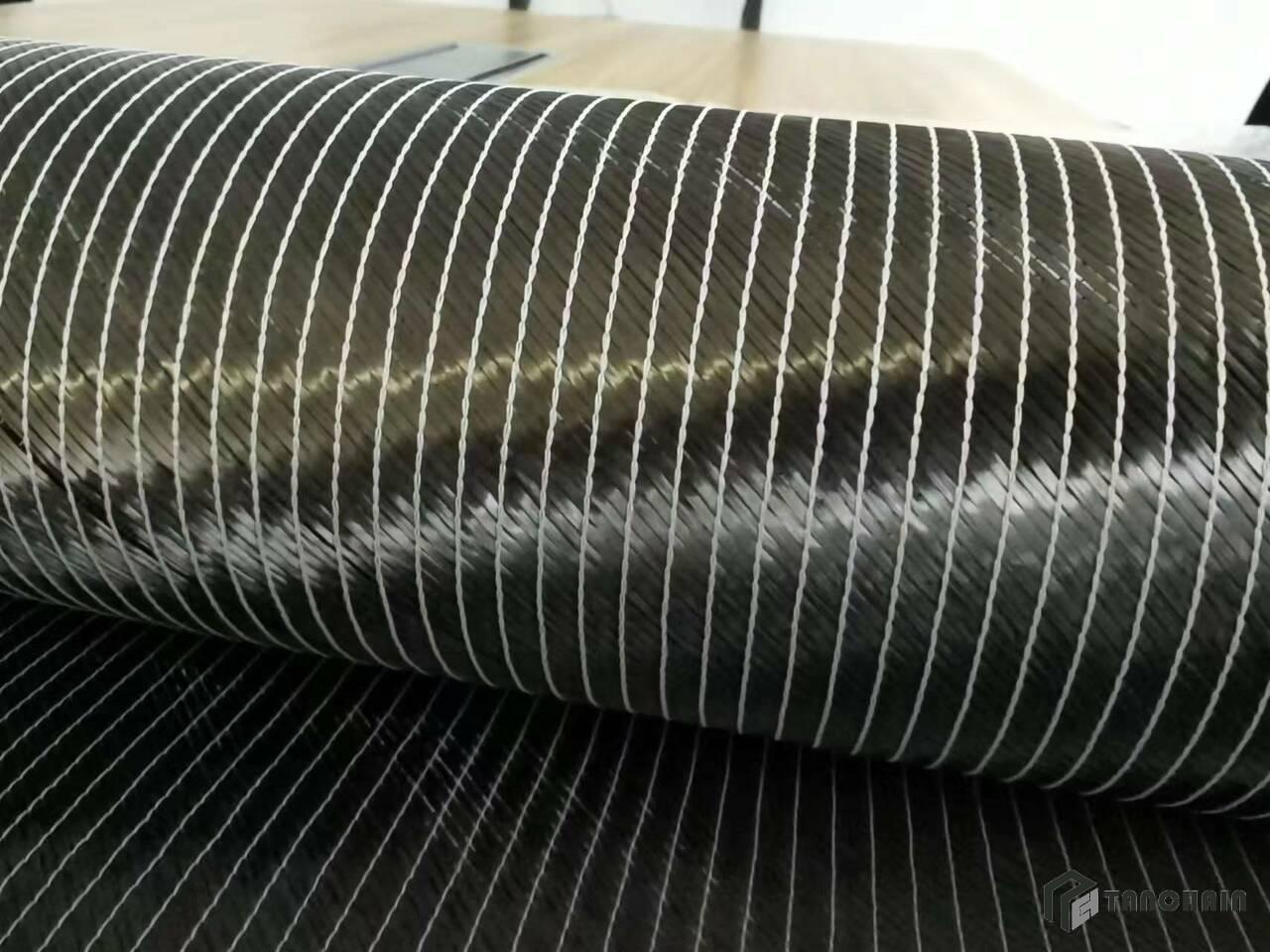

600gsm - Biaxial carbon fiber fabrics - +45/-45 - 18oz

- Code:TC-CF-X600B

- Material:12K carbon fiber

- Weight:600g

- Function:Reinforcement, boat construction etc.

- Weave:Warp knitting +45/-45

- Width:127cm 254cm

SEND INQUIRY

Product description:

Carbon fiber biaxial fabric is a high-performance textile material with excellent physical properties and wide application.

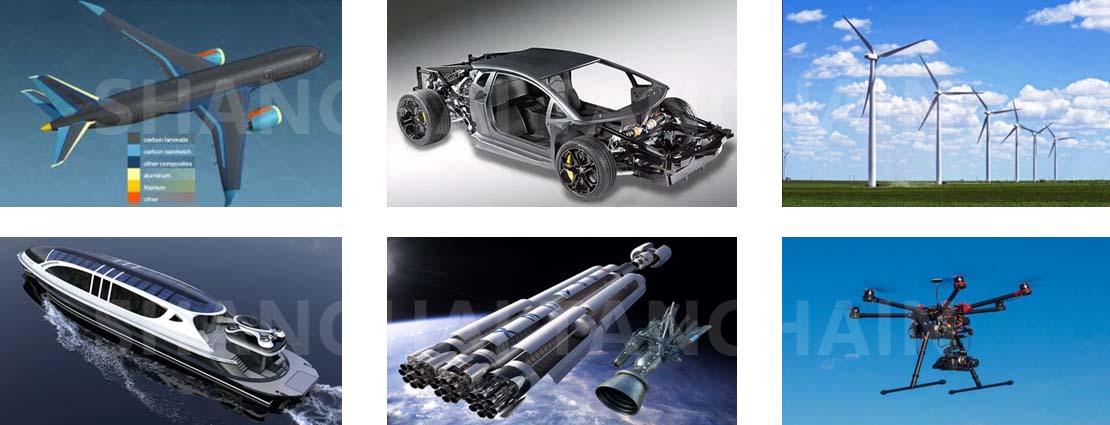

The main characteristics of carbon fiber biaxial fabric are its physical properties, including high strength, high modulus, low density, small linear expansion coefficient, etc. These characteristics make carbon fiber known as the "king of new materials". Compared with metal materials such as titanium, steel, aluminum, etc., carbon fiber exhibits extremely high strength along the fiber axis direction, and its specific gravity is small, which makes the specific strength and specific modulus comprehensive index of carbon fiber reinforced epoxy resin composite materials rank among the top in existing structural materials. In addition, the tensile strength of carbon fiber resin composite materials is generally above 3500 MPa, which is 7 to 9 times that of steel, and the tensile elastic modulus is 230 to 430 GPa, which is also higher than steel. These characteristics make carbon fiber widely used in aviation, aerospace, automobiles, ships, armored vehicles, wind power generation and other fields.

In the production process of biaxial fabric, two weaving shafts must be wound separately, and the warps must be fed separately to weave into a product. This kind of fabric can give full play to the performance of the fiber in both the longitudinal and transverse directions, providing better structure and performance. Multi-axial technology is a new weaving technology developed on the basis of uniaxial and biaxial technology. It allows reinforcing yarns to be inserted at a certain angle in the longitudinal, transverse or oblique direction of the fabric according to the use requirements, so as to give full play to the performance of each component in the fabric structure. This technology is characterized by large demand, high production efficiency and low production cost. It is widely used in wind turbine blades, vehicle and ship parts, high-pressure vessels and sports equipment. In addition, the application of carbon fiber biaxial fabric also includes fiber-reinforced composite materials made by compounding it with resin as a skeleton material. This material not only has excellent physical properties, but also has excellent molding performance, which is suitable for manufacturing products of various complex shapes. The research and development and application of carbon fiber biaxial fabrics have greatly promoted the technological progress and development in the fields of aerospace, automobile industry, etc.

Parameters of bi-axial carbon fabric

| Product | 600gsm biaxial carbon fabric | |

| Item | Unit | Result |

| Gram weight | g/m² | 600 |

| Width | mm | 1270 |

| Thickness | mm | 0.9mm±0.09 |

| Pattern | +45/-45 | |

| Fiber Density(+45°) | /cm | 5.5 |

| Fiber Density(-45°) | /cm | 5.5 |

| Carbon fiber materials | K | 12K, T400 |

| Breaking strength | Mpa | 4000-4500 |

| Modulus | Gpa | >235 |

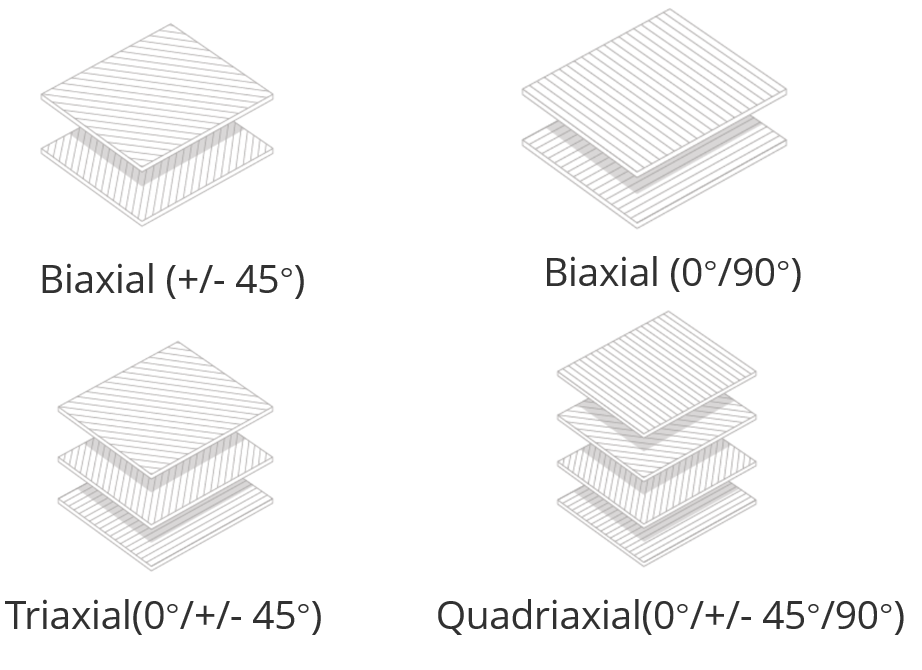

Pattern of axial carbon fabrics

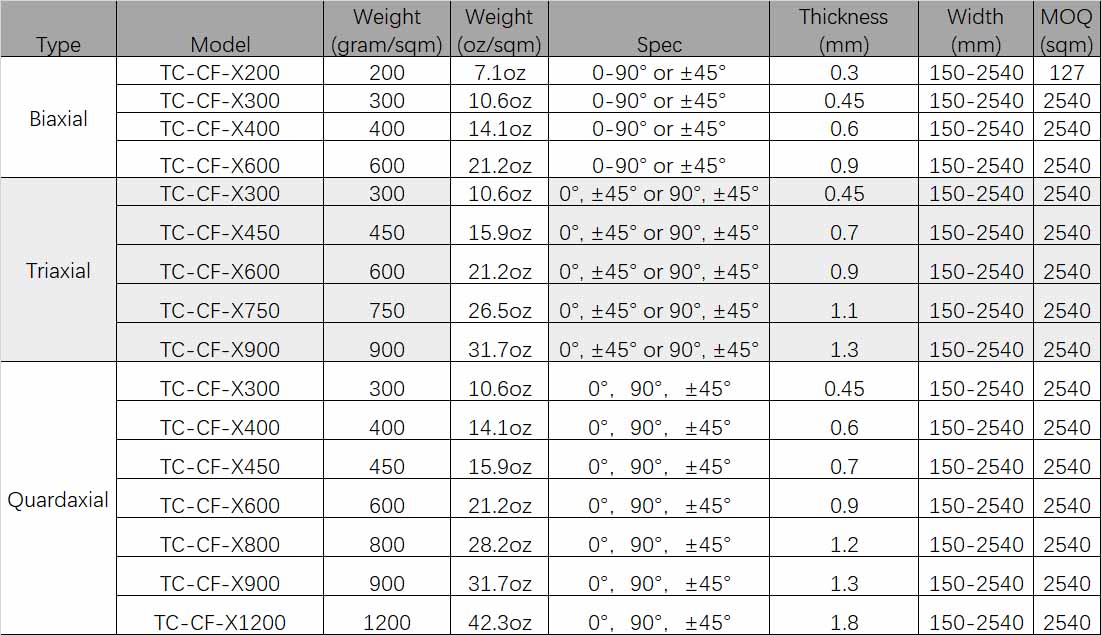

Product list of axial carbon fabrics

Product line of axial carbon fabric:

Shipping:

APPLICATIONS

Certificate