-

-

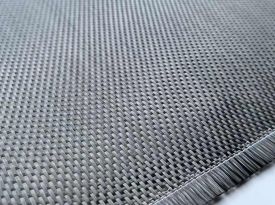

50K - Carbon fiber filaments

- Code:TC-CF-50K

- Material:100% Carbon Fiber

- Weight:50k filaments

- Function:High strength, Low weight.

- Color:Black

SEND INQUIRY

Characteristics of 50k carbon fiber filament:

- Physical properties:

- High strength: It has high tensile strength and can withstand large loads, providing reliable structural support for application products. For example, in some structural parts that need to withstand gravity or tension, 50k carbon fiber filament can play its strength advantage.

- High modulus: A high modulus means that the material deforms less when subjected to force, has good dimensional stability and rigidity, and can maintain the shape and precision of the structure.

- Low density: The density is much lower than that of metal materials, such as steel, and is a fraction of its weight. This makes products using 50k carbon fiber filament light in weight, easy to transport, install and use, and has important advantages in areas with strict weight requirements, such as aerospace, automotive and other industries.

- Other characteristics:

- Good fatigue resistance: After long-term repeated use and stress, 50k carbon fiber filament can still maintain good performance, is not prone to fatigue damage, and has a long service life.

- Corrosion resistance: It has good tolerance to chemicals such as acids, alkalis, and salts, and can maintain stable performance in harsh chemical environments, reducing maintenance and replacement costs.

- Easy processing: Compared with small-tow carbon fiber, 50k large-tow carbon fiber has certain advantages in processing, and is easier to perform weaving, winding and other processing operations, which can meet the needs of products of different shapes and structures.

Main uses:

- Industrial field:

- Wind power generation: It can be used to manufacture blades, towers and other components of wind turbines. Its light weight and high strength characteristics can meet the material performance requirements of wind power generation equipment, while reducing the weight of blades and improving power generation efficiency.

- Rail transit: It is used to manufacture body structural parts, interior parts, etc. of rail transit vehicles such as subways and high-speed railways. It can reduce the weight of vehicles, reduce energy consumption, and increase operating speed and safety.

- Construction field: It has a wide range of applications in the reinforcement and repair of building structures, such as strengthening beams and columns of bridges and buildings, which can improve the bearing capacity and seismic resistance of the structure.

- Sports and leisure field: It can be used to manufacture sports equipment such as bicycles, golf clubs, tennis rackets, skis, etc. It can improve the performance and quality of sports equipment and provide athletes with a better experience.

- Other fields: It also has certain applications in aerospace, shipbuilding, machinery manufacturing and other fields, such as manufacturing aircraft parts, ship shells, mechanical transmission parts, etc.

Advantages and disadvantages:

- Advantages:

- Excellent performance: It has excellent physical properties such as high strength, high modulus, low density, fatigue resistance, and corrosion resistance, and can meet the needs of a variety of complex application scenarios.

- Relatively low cost: Compared with small tow carbon fiber, 50k large tow carbon fiber has higher production efficiency and relatively low cost, which is conducive to reducing costs in large-scale applications.

- Wide range of applications: Due to its performance and cost advantages, 50k carbon fiber filament has broad application prospects in many fields such as industry, sports, aerospace, etc.

- Disadvantages:

- Slightly poor performance stability: Compared with small-tow carbon fiber, the performance stability of 50k carbon fiber filament may be slightly worse, mainly because the tow diameter of large-tow carbon fiber is larger, and the uniformity of the internal structure may be affected to a certain extent.

- Processing difficulty still exists: Although it is easier to process than small-tow carbon fiber, the processing of 50k carbon fiber filament still requires special equipment and processes, and the processing technology requirements are high. Problems such as fiber breakage and hair may occur during the processing.

- Difficulty in recycling: Carbon fiber materials are difficult to recycle, and 50k carbon fiber filament is no exception. At present, the recycling technology of carbon fiber materials is not mature enough, and the recycling cost is high, which to a certain extent limits its sustainable development.

Cost-effectiveness:

- From the perspective of performance: 50k carbon fiber filament has excellent performance and can provide products with advantages such as high strength, high stiffness, and light weight. In some fields with high requirements for material performance, such as aerospace, high-end sports equipment, etc., its performance advantages can bring higher added value, so the cost-effectiveness is relatively high.

- From the perspective of cost: With the continuous advancement of production technology and the expansion of production capacity, the cost of 50k carbon fiber filament is gradually reduced. Compared with small-tow carbon fiber, its cost advantage is more obvious. In some cost-sensitive industrial fields, such as wind power generation and rail transit, 50k carbon fiber filament has a higher cost-effectiveness.

- Comprehensive consideration: Taking into account performance and cost factors, 50k carbon fiber filament has a good cost-effectiveness in large-scale application scenarios. However, for some fields with extremely high performance requirements and insensitive to cost, small-tow carbon fiber may still be the first choice.

Development prospects:

- Market demand growth: Driven by the "dual carbon" goal, the demand for lightweight materials in various industries is increasing. As a high-performance lightweight material, 50k carbon fiber filament has broad market prospects. Especially in the fields of wind power generation, rail transit, new energy vehicles, etc., the demand for 50k carbon fiber filament will continue to grow.

- Continuous technological progress: With the continuous increase in R&D investment, the production technology of 50k carbon fiber filament will continue to improve, product performance will be further improved, and costs will be further reduced. At the same time, the recycling technology of carbon fiber materials will continue to develop, which will help improve its sustainability.

- Expansion of application fields: In the future, the application fields of 50k carbon fiber filament will continue to expand. In addition to the existing application fields, it will also be widely used in medical devices, electronic communications and other fields, providing new opportunities for its development.

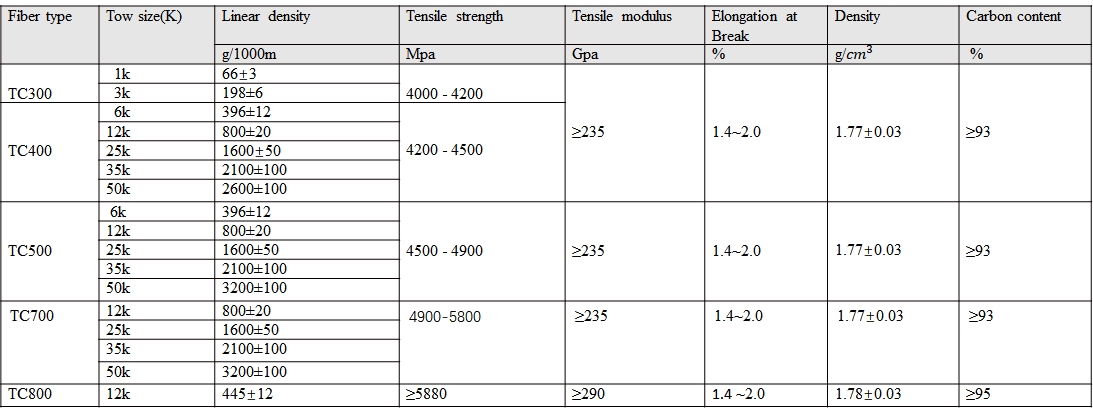

Technical Data

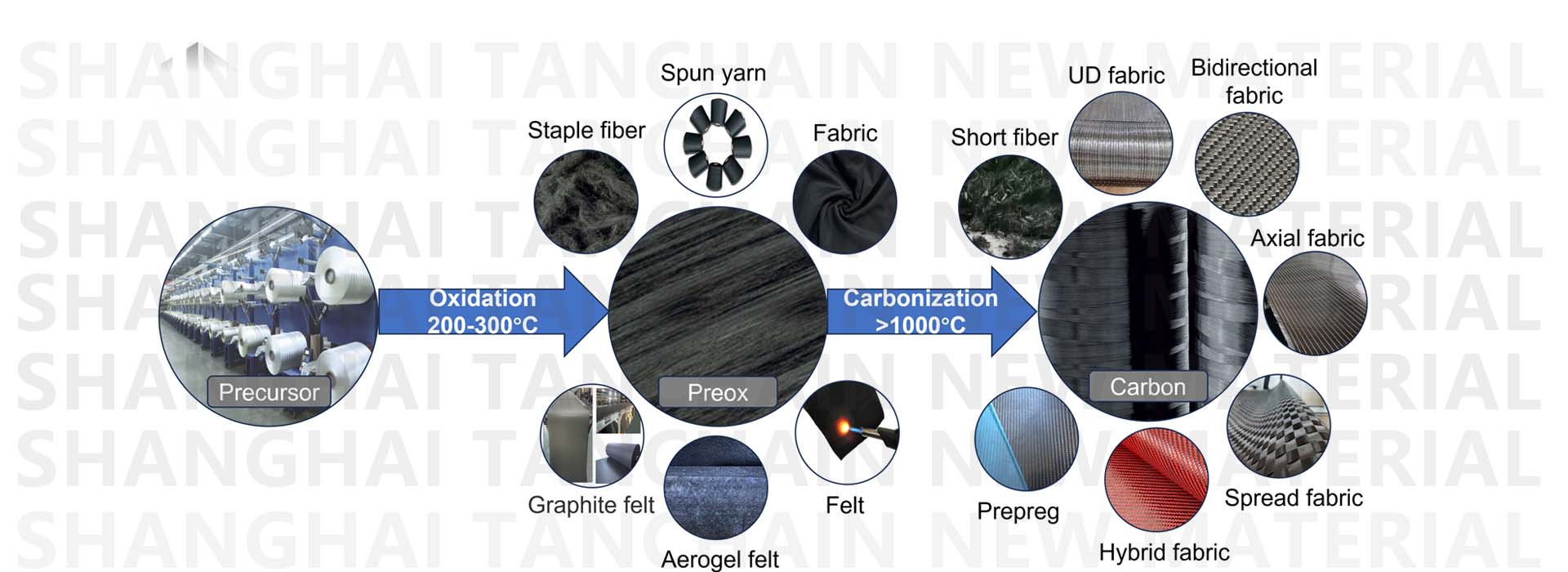

Production Line

Tanchain's Production Flow

SHIPPING