-

-

6K - 300gsm - Twill - Carbon Fabric

- Code:TC-CF-6KC300T

- Material:100% Carbon Fiber

- Weight:300gsm

- Function:High strengh, Low weight, Good looking, High modulus

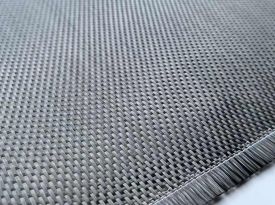

- Color:Black

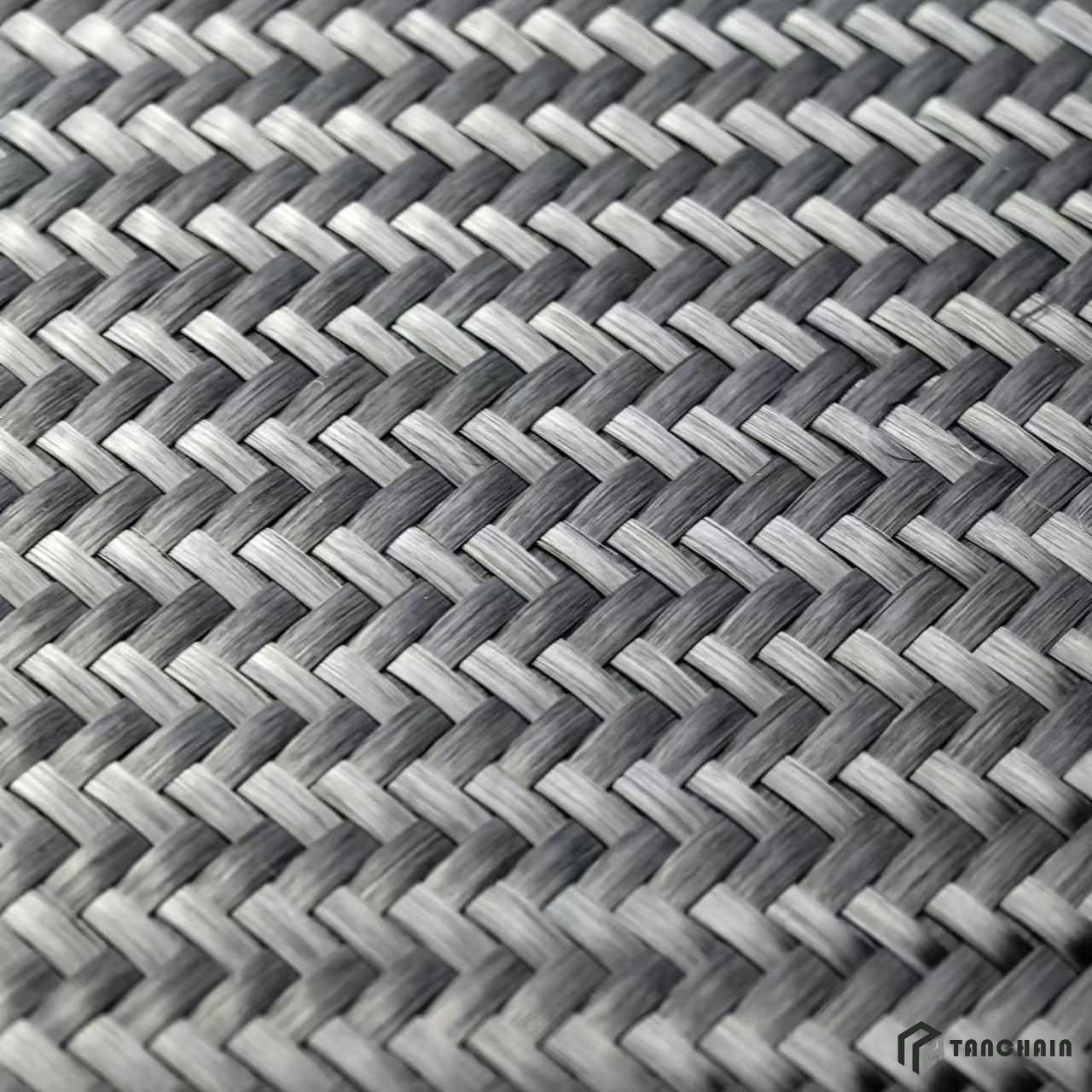

- Weave:Twill

- Width:10-150cm

SEND INQUIRY

Material: |

100% carbon fiber | Yarn (warp): | 6k carbon fiber |

| Pattern: | Twill | Yarn (weft): | 6k carbon fiber |

| Weight : | 300gsm | Width: | 10-150cm |

| Density(warp): | 4/10mm | Thickness: | 0.45mm |

| Density(weft): | 4/10mm | Color: | Black |

Material: |

100% carbon fiber |

| Pattern: | Twill |

| Weight : | 300gsm |

| Density(warp): | 4/10mm |

| Density(weft): | 4/10mm |

| Yarn Count(warp): | 6k carbon fiber |

| Yarn Count(weft): | 6k carbon fiber |

| Width: | 100-150cm |

| Thickness: | 0.45mm |

| Color | Black |

Product Description

6K 300g twill carbon fiber fabric has the following characteristics:

1. Physical properties:

- High strength: Carbon fiber itself has high strength, and 6K carbon fiber bundles further enhance the strength of this fabric. Compared with some ordinary materials, its tensile strength is extremely excellent, and it can withstand greater tension and stress, and performs well in application scenarios that require high strength.

- High stiffness: The twill weave method changes the fiber arrangement angle of the carbon fiber fabric in both the warp and weft directions, increasing the material's resistance to deformation and stiffness. This feature enables it to maintain good stability and shape when subjected to loads such as bending and shearing.

- Lightweight: Carbon fiber materials have a low density, and 6K 300g twill carbon fiber fabric also has the characteristics of light weight. This is a very important advantage for some application fields that have strict weight restrictions, such as aerospace, automobiles, etc., which can reduce the weight of the overall structure and improve the performance and efficiency of the equipment.

- Low thermal expansion coefficient: Carbon fiber has a low thermal expansion coefficient. 6K 300g twill carbon fiber fabric has good dimensional stability when the temperature changes. It is not easy to expand or shrink significantly due to temperature changes, and can maintain stable performance under different temperature environments.

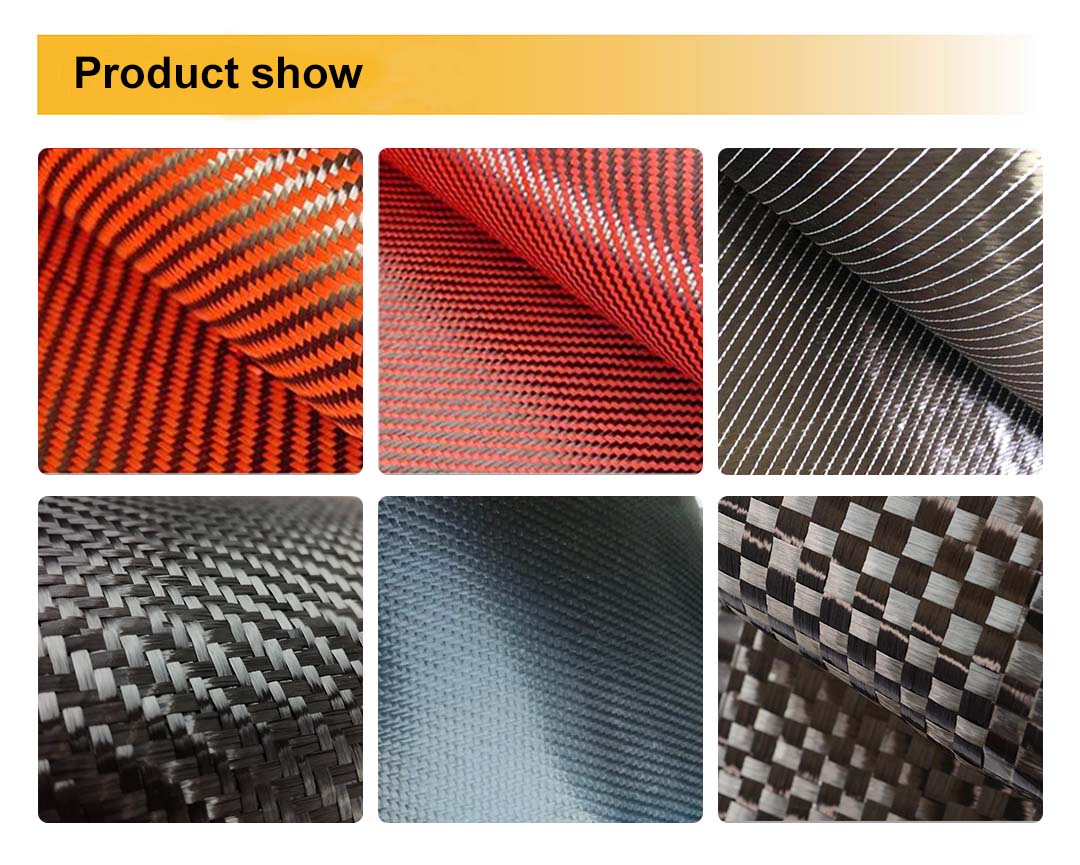

2. Appearance characteristics:

- Beautiful texture: The twill weaving method forms a unique diagonal texture, which has a certain aesthetic and decorative effect. This texture makes the carbon fiber fabric different from the plain or other woven carbon fiber fabrics in appearance, and can better meet some application scenarios with high requirements for appearance.

- Easy to fit complex shapes: Twill carbon fiber fabric is relatively soft and easier to fit various complex shapes and curved surfaces. In practical applications, it can better adapt to components of different shapes and improve the bonding effect with the matrix material.

3. Chemical properties:

- Corrosion resistance: Carbon fiber has good corrosion resistance and has strong resistance to chemical substances such as acids, alkalis, and organic solvents. 6K 300g twill carbon fiber fabric inherits this characteristic and can maintain stable performance in harsh chemical environments and is not easily corroded or damaged.

- Good conductivity: Carbon fiber is a good conductive material. 6K 300g twill carbon fiber fabric can be used in occasions where conductive properties are required, such as the housing of electronic equipment, electromagnetic shielding, etc.

Its uses mainly include the following aspects:

1. Aerospace field:

In aerospace equipment such as aircraft and spacecraft, the performance requirements of materials are extremely high. The high strength, high stiffness, and light weight of 6K 300g twill carbon fiber fabric enable it to be used to manufacture aircraft wings, fuselage structural parts, satellite structural parts, etc., which can reduce the weight of aircraft and improve flight performance and fuel efficiency.

2. Automobile field:

It can be used for automobile modification and the manufacture of high-performance parts. For example, it can be used for automobile body shells, hoods, spoilers and other parts to improve the strength and stiffness of the car, while reducing the weight of the car body and improving the acceleration and handling performance of the car. In addition, in the field of racing, twill carbon fiber fabrics are widely used in the manufacture of racing car bodies and parts to meet the demand for high-performance materials in racing cars.

3. Sporting goods field:

suitable for manufacturing high-end sports equipment, such as bicycles, golf clubs, tennis rackets, fishing rods, etc. These sports equipment need to have lighter weight and higher strength to improve athletes' experience and competitive performance.

4. Construction field:

It has important applications in the reinforcement and repair of building structures. It can be used to reinforce concrete structures, bridges, piers and other building components to improve their bearing capacity and seismic resistance. Twill carbon fiber fabrics are easy to construct, can quickly and effectively reinforce building structures, and will not increase excessive structural deadweight.

5. Electronic equipment field:

Due to its good conductivity and electromagnetic shielding, it can be used to manufacture electronic equipment housings, radiators, circuit boards and other components. It can protect electronic equipment from electromagnetic interference and improve the stability and reliability of the equipment.

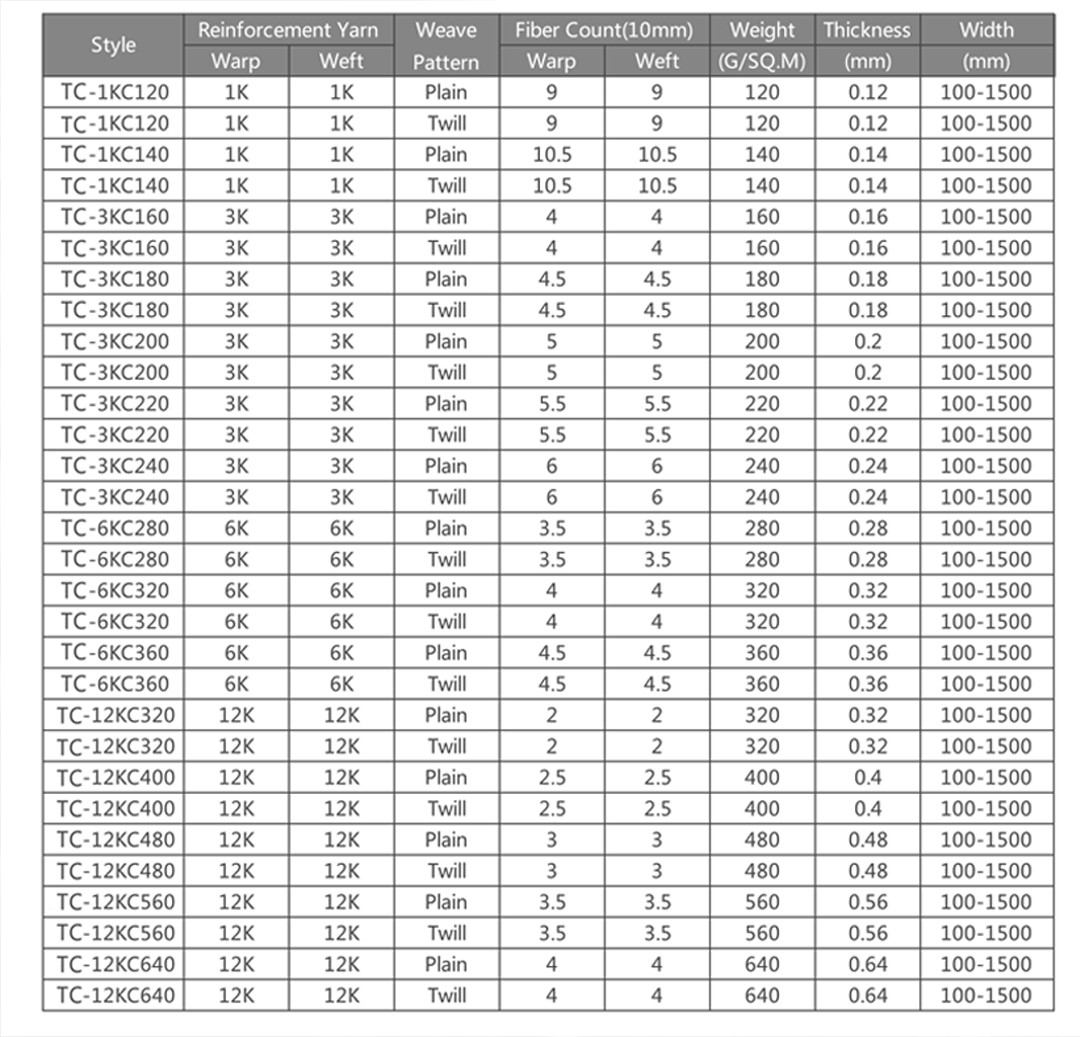

Similar Series Technical Data