-

-

6mm - Rice shaped - Carbon fiber chopped - PA66, PA6, PC, PPA

- Code:TC-CCF-006RI

- Material:100% Carbon Fiber

- Weight:6mm

- Function:Reinforcement.

- Color:Black

SEND INQUIRY

Material: |

95% carbon fiber | Length: | 6mm |

| Shape: | Rice shaped | Fiber Tenacity: | 4150Mpa/4950Mpa/5900Mpa |

| Sizing Type: |

PU/PA/EP/PEEK/PP | Color | Black |

| Sizing content: |

4-5% | Recommended matrix resin: | PA66, PA6, PC, PPA/PEEK, PEKK, PAEK/PP |

| Application: |

Modification and reinforcement | Other matrix resin: | POM, ABS, PBT, PC, LCP |

Material: |

95% carbon fiber |

| Shape: | Rice shaped |

| Sizing Type: | PU/PA |

| Sizing content: | 4-5% |

| Application: | Modification and reinforcement |

| Length: | 6mm |

| Fiber Tenacity: | 4150Mpa/4950Mpa/5900Mpa |

| Color: | Black |

| Recommended matrix resin: | PA66, PA6, PC, PPA/PEEK, PEKK, PAEK/PP |

| Other matrix resin: | POM, ABS, PBT, PC, LCP |

PRODUCT DESCRIPTION

There are mainly the following types of carbon fiber chopped short:

- Classification by raw materials:

- PAN-based carbon fiber chopped short: This type of carbon fiber is made of polyacrylonitrile (PAN). It has high strength and modulus and is currently the most widely used carbon fiber chopped short material. For example, it is used in plastic composites of some non-critical structural components in the aerospace field to effectively improve material performance.

- Asphalt-based carbon fiber chopped short: With asphalt as raw material, it has outstanding performance in some special properties, such as good thermal conductivity, and is suitable for use in plastic products that require heat dissipation.

- Classification by length: Carbon fiber chopped short lengths vary, and common lengths are 3mm, 4.5mm, 6mm, etc. Different lengths are suitable for different plastic processing processes and product requirements. For example, shorter carbon fiber chopped short (3mm) is easier to disperse evenly in injection molded plastics.

In the field of plastic reinforcement, carbon fiber chopped short has these applications:

- Enhanced mechanical properties: Adding carbon fiber chopped short to plastic can significantly improve the strength, modulus and hardness of plastics. For example, after adding carbon fiber chopped shorts to nylon plastic, its tensile strength and bending strength are greatly improved, and it can be used to manufacture mechanical parts.

- Improve heat resistance: It can increase the heat deformation temperature of plastics. For example, adding carbon fiber chopped shorts to polycarbonate plastics can enable the material to maintain good dimensional stability and mechanical properties under high temperature environments, which is suitable for plastic parts around automobile engines.

- Improve conductivity: Make the originally insulating plastic have a certain conductivity, which can be used to manufacture antistatic or electromagnetic shielding plastic products, such as the casing of electronic equipment.

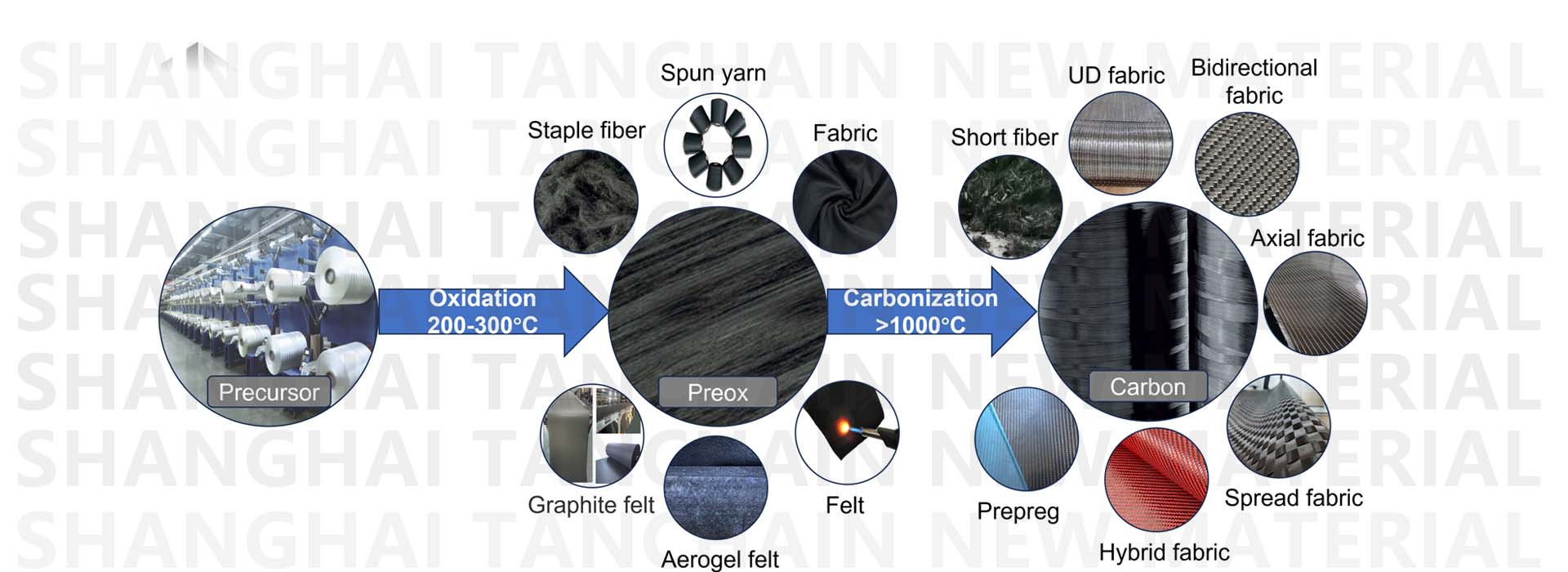

Production Line

Tanchain's Production Flow

SHIPPING