-

-

6mm - Cylindrical - Carbon fiber chopped - PA66, PA6, PC, PPA

- Code:TC-CCF-006CY

- Material:100% Carbon Fiber

- Weight:6mm

- Function:Reinforcement.

- Color:Black

SEND INQUIRY

Material: |

95% carbon fiber | Length: | 6mm |

| Shape: | Cylindrical | Fiber Tenacity: | 4150Mpa/4950Mpa/5900Mpa |

| Sizing Type: |

PU/PA | Color | Black |

| Sizing content: |

4-6% | Recommended matrix resin: | PA66, PA6, PC, PPA |

| Application: |

Modification and reinforcement | Other matrix resin: | POM, ABS, PBT |

Material: |

95% carbon fiber |

| Shape: | Cylindrical |

| Sizing Type: | PU/PA |

| Sizing content: | 4-6% |

| Application: | Modification and reinforcement |

| Length: | 6mm |

| Fiber Tenacity: | 4150Mpa/4950Mpa/5900Mpa |

| Color: | Black |

| Recommended matrix resin: | PA66, PA6, PC, PPA |

| Other matrix resin: | POM, ABS, PBT |

PRODUCT DESCRIPTION

Cylindrical carbon fiber chopped has the following characteristics:

Appearance shape and dimensional accuracy

- Regular shape: cylindrical, regular and uniform shape, when mixed with the matrix material, it can be more evenly dispersed in it, which helps to improve the overall performance of the composite material and avoid problems such as stress concentration caused by irregular shape.

- High dimensional accuracy: high requirements for raw materials and processing equipment, difficult processing, but correspondingly has higher dimensional accuracy and better consistency, which can better meet some application scenarios with strict requirements on chopped fiber size.

Processing and feeding performance

- Smooth feeding: The feeding capacity of the twin-screw extruder is stronger than that of chopped carbon fibers in other shapes such as flakes and irregular shapes. It can enter the processing equipment more smoothly during the processing process, improve production efficiency and reduce production costs.

Mechanical properties

- High strength and high modulus: Inheriting the high strength and high modulus characteristics of carbon fiber, it can significantly improve the strength, stiffness and deformation resistance of composite materials, and can be used to manufacture parts with high mechanical performance requirements.

Physical and chemical properties

- Low density: Low density can enhance material performance without adding too much weight, and is suitable for products that require lightweight, such as aerospace, automobile manufacturing and other fields.

- Strong corrosion resistance: It has good corrosion resistance and can be used to manufacture products in some harsh environments to extend the service life of the product.

- Good conductivity: It has a certain conductivity, which can make composite materials have conductive properties and is used to manufacture electromagnetic shielding materials, antistatic materials, etc.

Stability

- Good thermal stability: It has good thermal stability and can maintain stable performance within a certain temperature range. It can be used in the manufacture of components in high temperature environments, but its antioxidant performance is relatively low. In high temperature aerobic environments, it is necessary to pay attention to its upper limit of use.

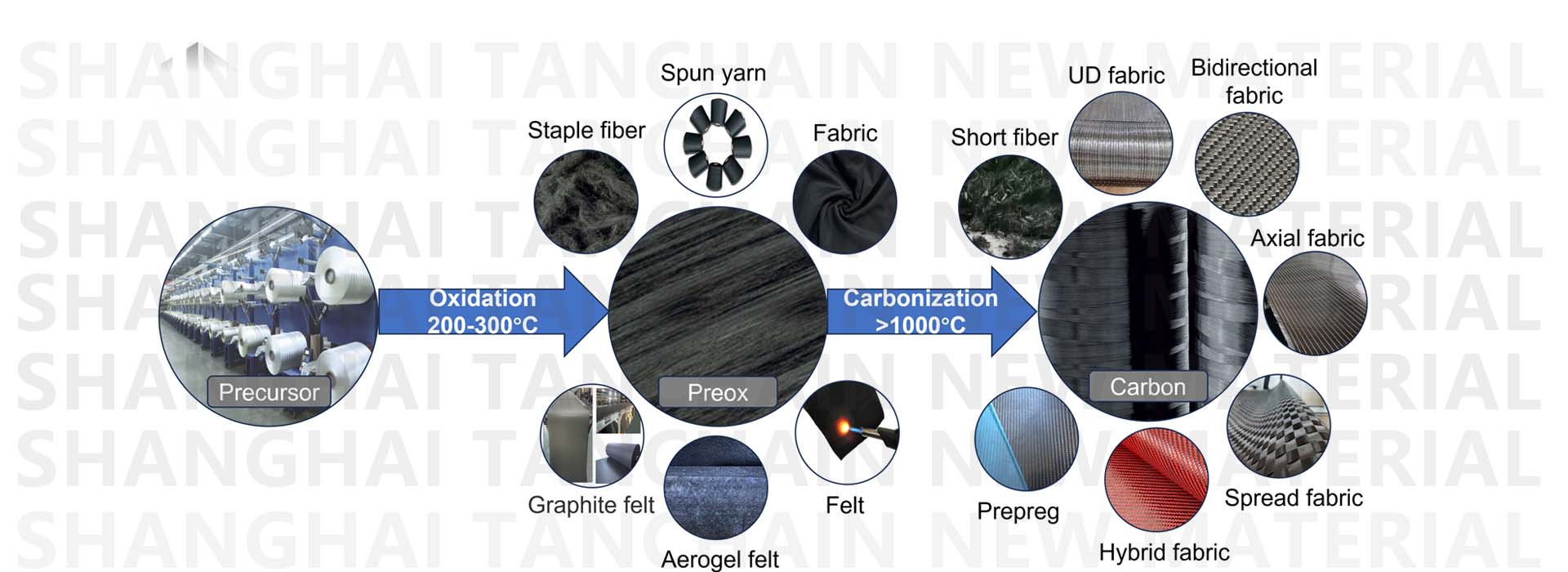

Production Line

Tanchain's Production Flow

SHIPPING