-

-

2mm - Carbon fiber rope

- Code:TC-CF-RD2

- Material:100% Carbon Fiber

- Weight:3mm: 384m/kg

- Function:High temperature resistant, UV resistant, Conductive

- Color:Black

SEND INQUIRY

| Length | 384m/kg |

| Diameter | 2mm(customized 1-10mm) |

The main differences between carbon fiber rope and aramid rope are as follows:

Raw materials and manufacturing process

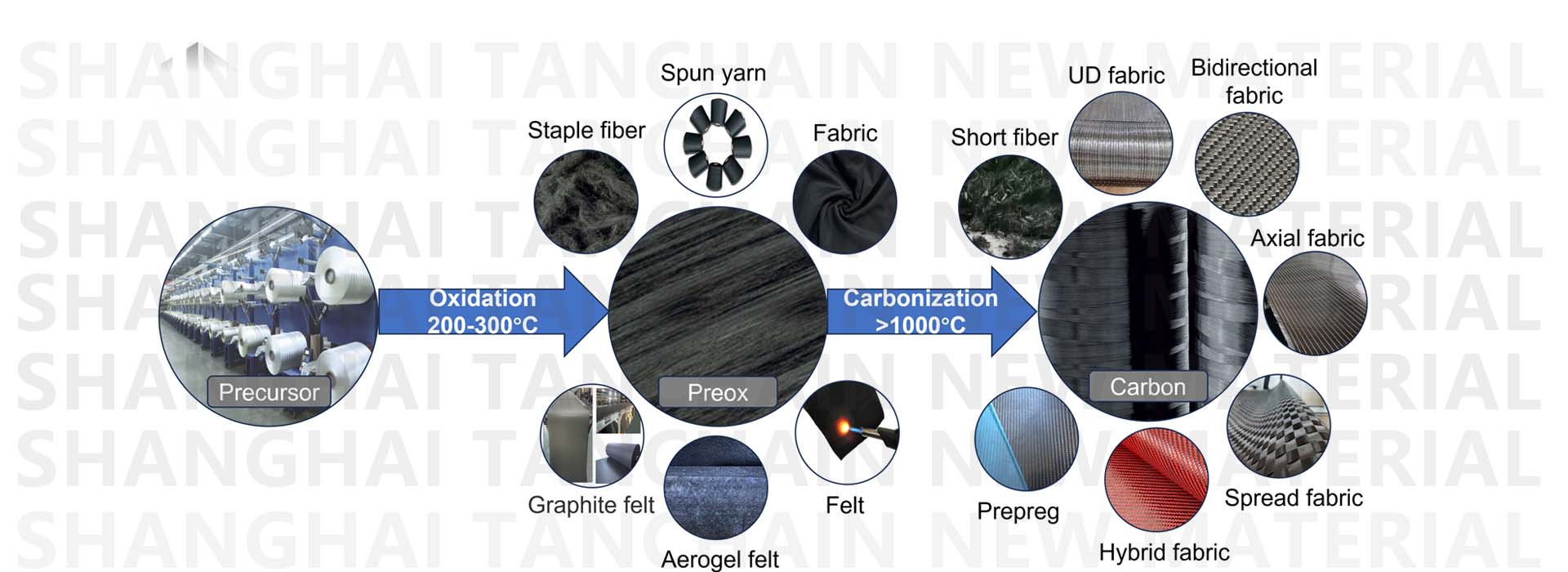

- Carbon fiber rope: mainly made of carbon fiber. Carbon fiber is a fiber with extremely high carbon content obtained by pre-oxidation and carbonization of organic fibers such as polyacrylonitrile (PAN) at high temperature. Carbon fiber rope is made by twisting carbon fiber and other textile processes.

- Aramid rope: The main component is aromatic polyamide fiber. It is made of polymers connected by amide groups and aromatic rings, and is made into fibers through processes such as solution spinning, and then woven into ropes.

Mechanical properties

- Strength

- Carbon fiber rope: It has extremely high strength, and its tensile strength can usually reach 3000-7000MPa, and the strength is higher in some high-performance carbon fiber ropes. It can withstand huge tensile forces and performs well in application scenarios with extremely high strength requirements.

- Aramid rope: The strength is also high, and the tensile strength is generally around 2800-3400MPa. Although it is slightly lower than carbon fiber, it can still meet the requirements of many high-strength applications.

- Modulus

- Carbon fiber rope: The modulus is relatively high, usually between 230-600GPa, which makes it less deformed when subjected to tension and can provide stable support for the structure.

- Aramid rope: The modulus is relatively low compared to carbon fiber rope, about 60-120GPa, and it will have relatively large deformation when subjected to force.

- Toughness

- Carbon fiber rope: It is relatively brittle and is prone to breakage when subjected to sudden impact or excessive bending, and has poor toughness.

- Aramid rope: It has good toughness, good impact resistance, can absorb and disperse energy, and will not break easily when subjected to impact.

Temperature resistance

- Carbon fiber rope: It has excellent high temperature resistance. In the absence of oxygen, it can withstand high temperatures of up to 2000-3000℃, and in an aerobic environment, it can also withstand high temperatures of several hundred degrees Celsius, and has good thermal stability.

- Aramid rope: The high temperature resistance is relatively weak, and the long-term use temperature is generally between -196℃-200℃. Beyond this temperature range, its performance will be significantly reduced.

Chemical stability

- Carbon fiber rope: It has stable chemical properties and is resistant to most chemicals such as acids, alkalis, organic solvents, etc., and is not easily corroded.

- Aramid rope: It also has a certain tolerance to most chemicals, but in some strong acid and alkali environments, chemical reactions such as hydrolysis may occur, resulting in performance degradation.

Price

- Carbon fiber rope: Due to the high production cost of carbon fiber and the complex manufacturing process, the price of carbon fiber rope is relatively expensive.

- Aramid rope: The price is lower than that of carbon fiber rope, with high cost performance, and it has more advantages in some cost-sensitive application scenarios.

Production Line

Tanchain's Production Flow

SHIPPING