-

-

1K - Pre-oxidized PAN Fiber Filaments

- Code:TC-PX-1K

- Material:100% PAN oxidized fiber

- Weight:1k filaments

- Function:Non-conductive, Good spinnability

- Color:Black

SEND INQUIRY

Product description

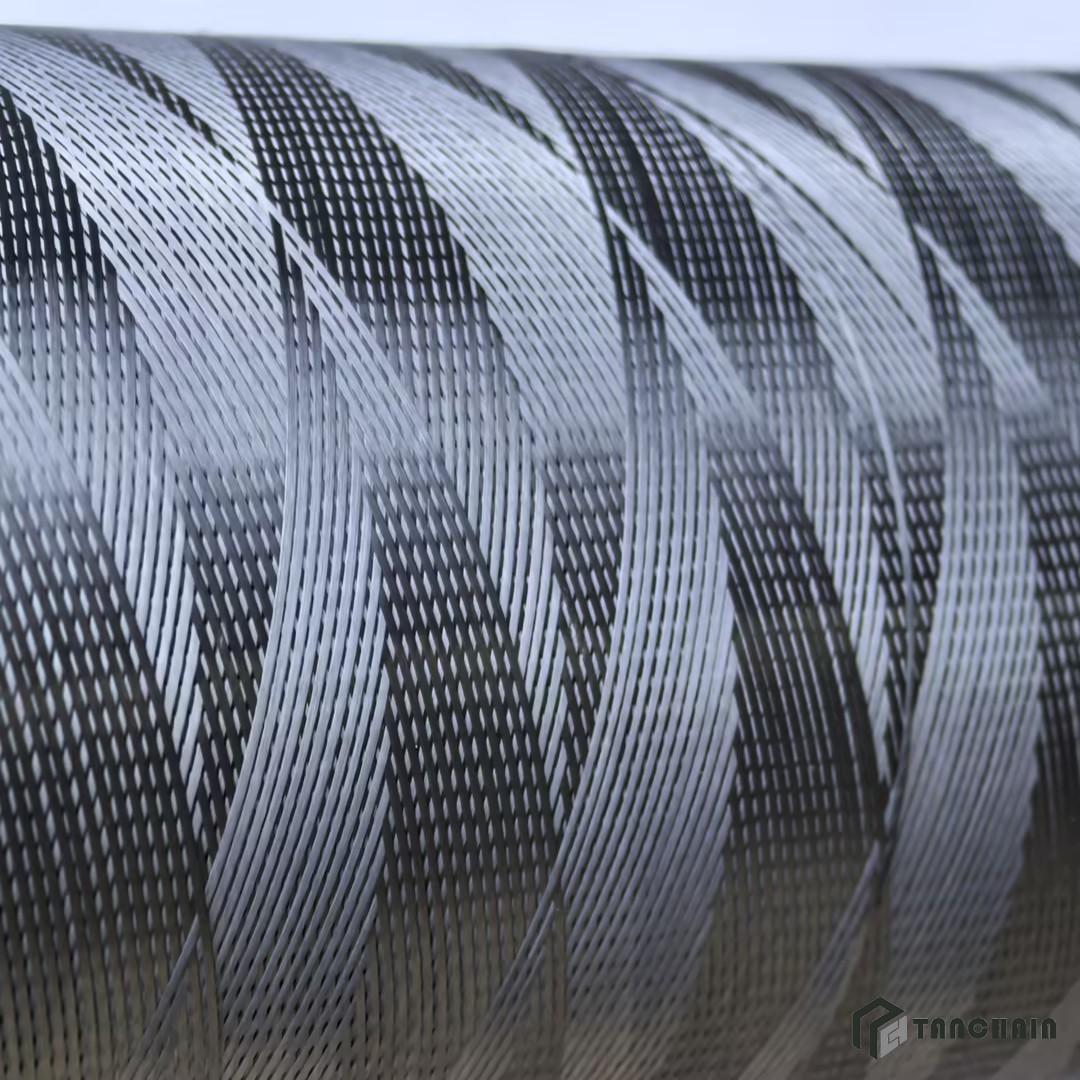

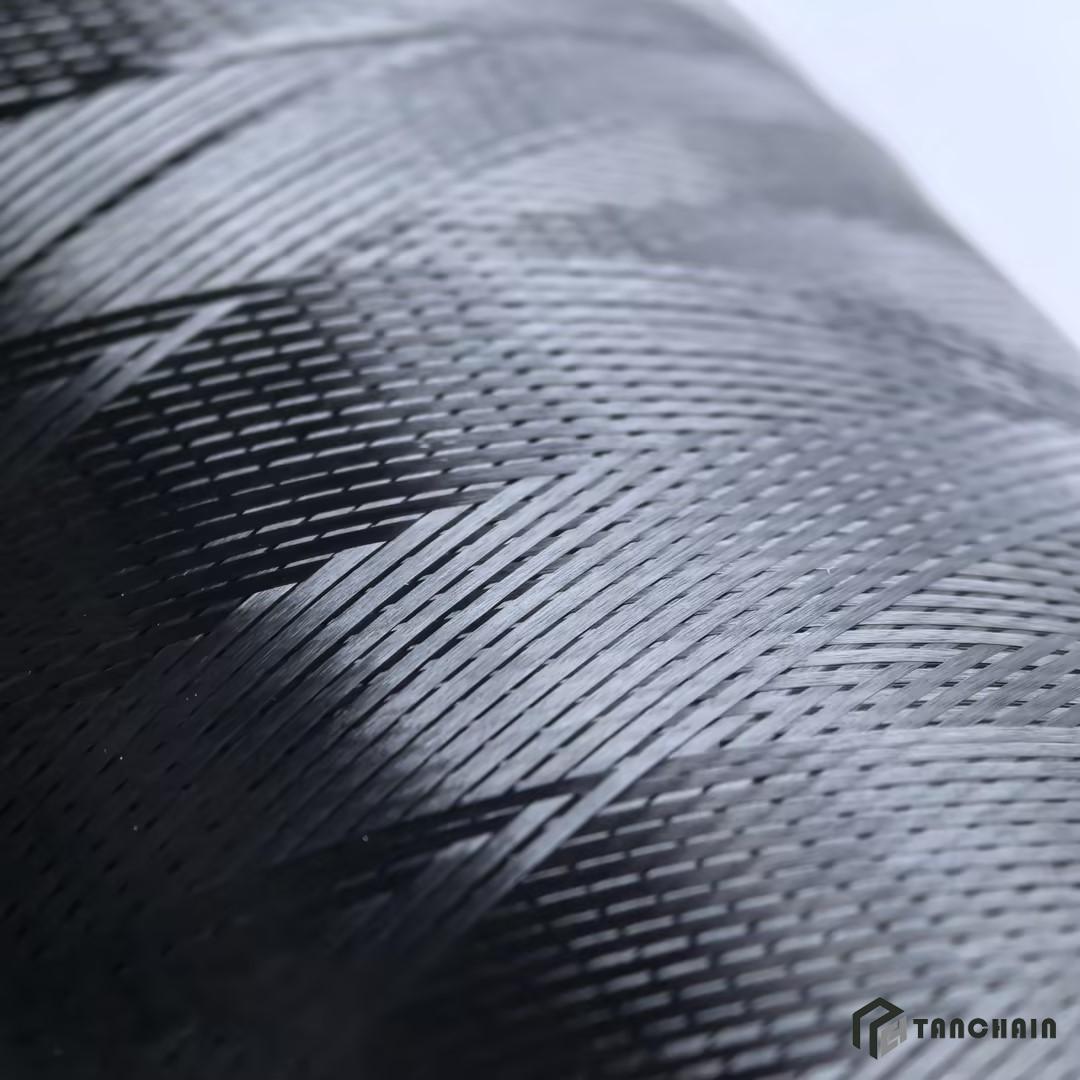

1. Structural advantages of plain fabrics

- Plain weave is the simplest fabric structure, with warp and weft yarns interlaced one above and one below. This structure makes the fabric strong, because there are the most interlacing points between the yarns, the mutual restraint is strong, and the yarns are not easily displaced under external forces. For 1k pre-oxidized fiber filaments, they have certain strength and stability, and the plain weave structure can better exert these characteristics, so that the fabric can withstand greater tension and friction.

- The surface of the plain fabric is flat, and the front and back sides look the same. When the functionality of 1k pre-oxidized fiber filaments (such as flame retardancy, heat insulation, etc.) needs to be utilized, the plain weave structure will not affect its function due to the complex fabric structure. For example, when making industrial fabrics for fireproof and heat insulation, plain fabrics can evenly distribute fibers, so that heat is evenly conducted on the surface of the fabric to avoid local overheating.

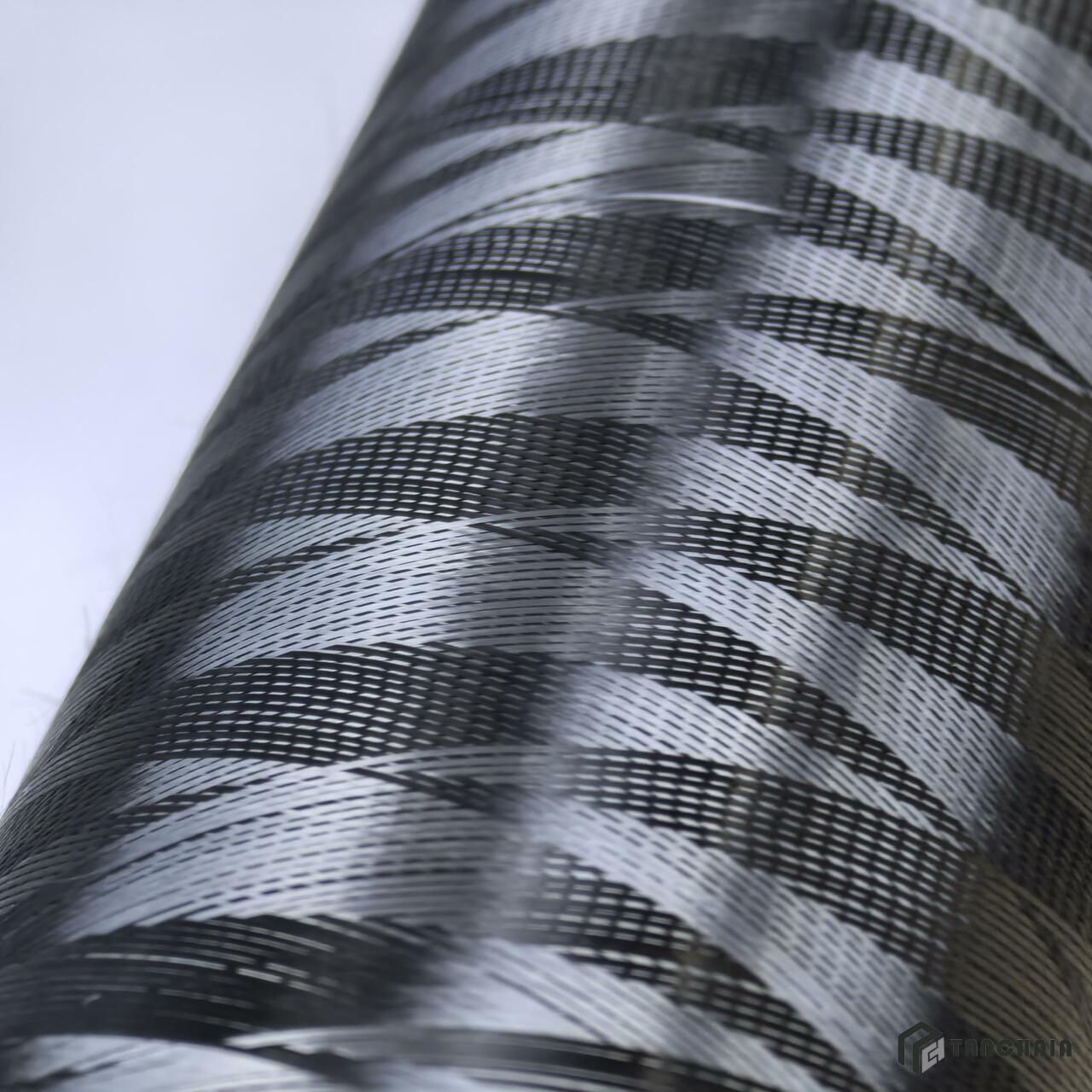

2. Effective use of functionality

- 1k pre-oxidized fiber filaments have the characteristics of high flame retardancy, excellent thermal stability, and good chemical stability. In plain fabrics, these fibers can be tightly interwoven to form an effective protective barrier. Since the plain fabric is tightly interwoven, it is difficult for the flame to penetrate the fabric when facing the flame, and the high flame retardancy of the fiber can prevent the flame from spreading. Moreover, in a high temperature environment, the plain structure helps to maintain the integrity of the fabric, so that the thermal stability of the fiber can be fully utilized and can effectively insulate.

- In terms of chemical protection, the tight structure of the plain fabric can also prevent chemicals from easily penetrating. When 1k pre-oxidized fiber filaments are used to make fabrics for chemical protective clothing, the plain weave method makes it difficult for chemicals to enter through the gaps in the fabric, thereby protecting the user.

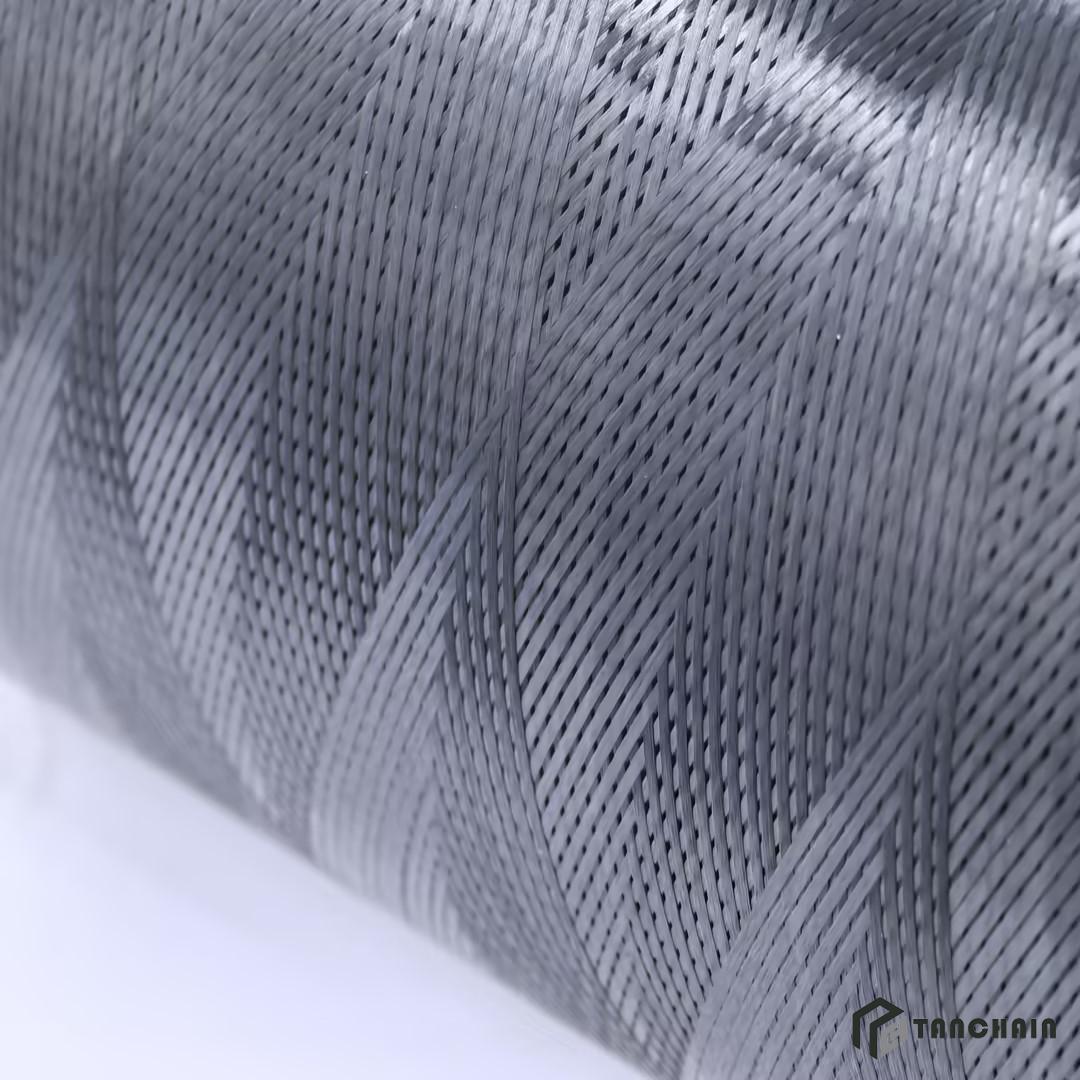

3. Convenience of processing

- Weaving plain fabrics is relatively simple, and its weaving process requirements are relatively low on textile equipment. For 1k pre-oxidized fiber filaments, which may require special treatment (such as surface treatment to increase cohesion), plain weaving can reduce fiber damage or weaving difficulties caused by complex weaving processes. Moreover, the parameters of plain fabrics (such as warp and weft density) are relatively easy to control, and the amount and arrangement of fibers can be adjusted according to specific usage requirements (such as different protection level requirements), so that the fabric can meet the required physical indicators such as thickness and weight while meeting the functionality.

Production Line

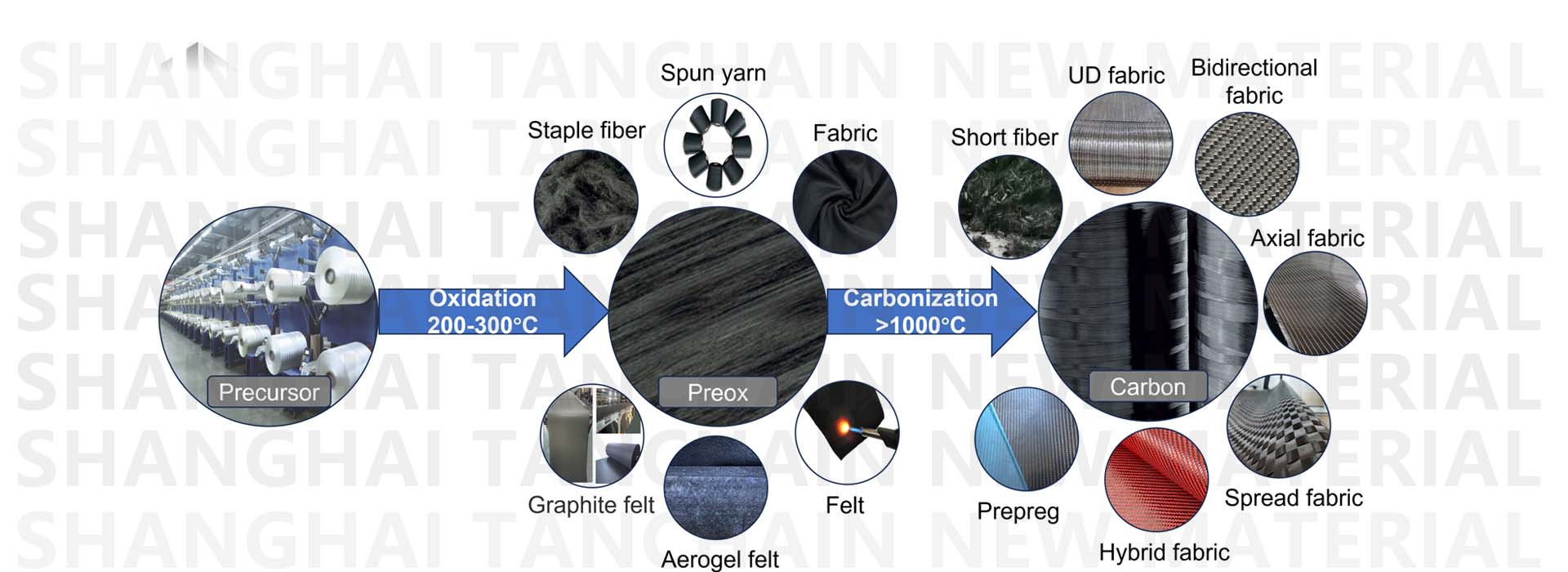

Tanchain's Production Flow

SHIPPING