-

-

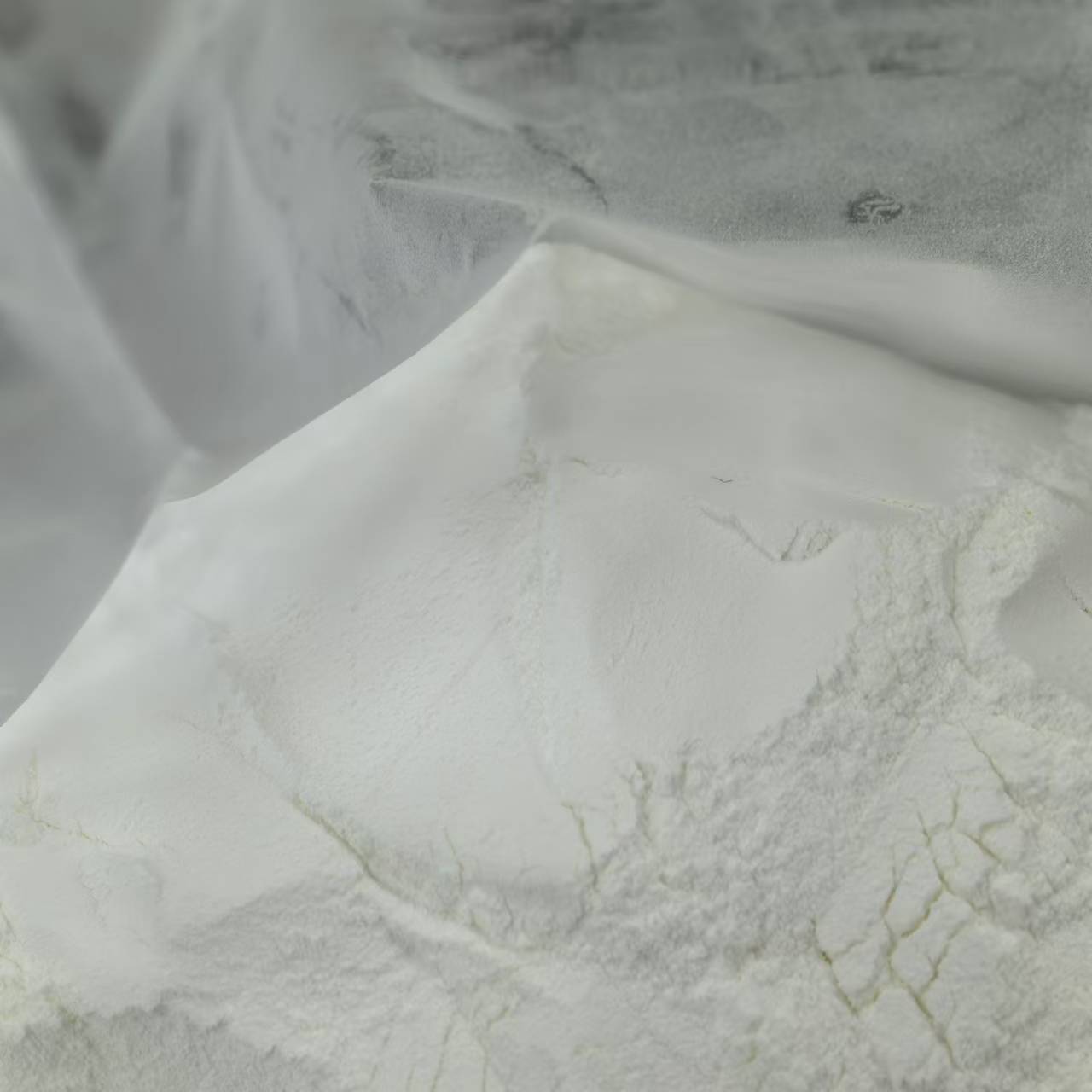

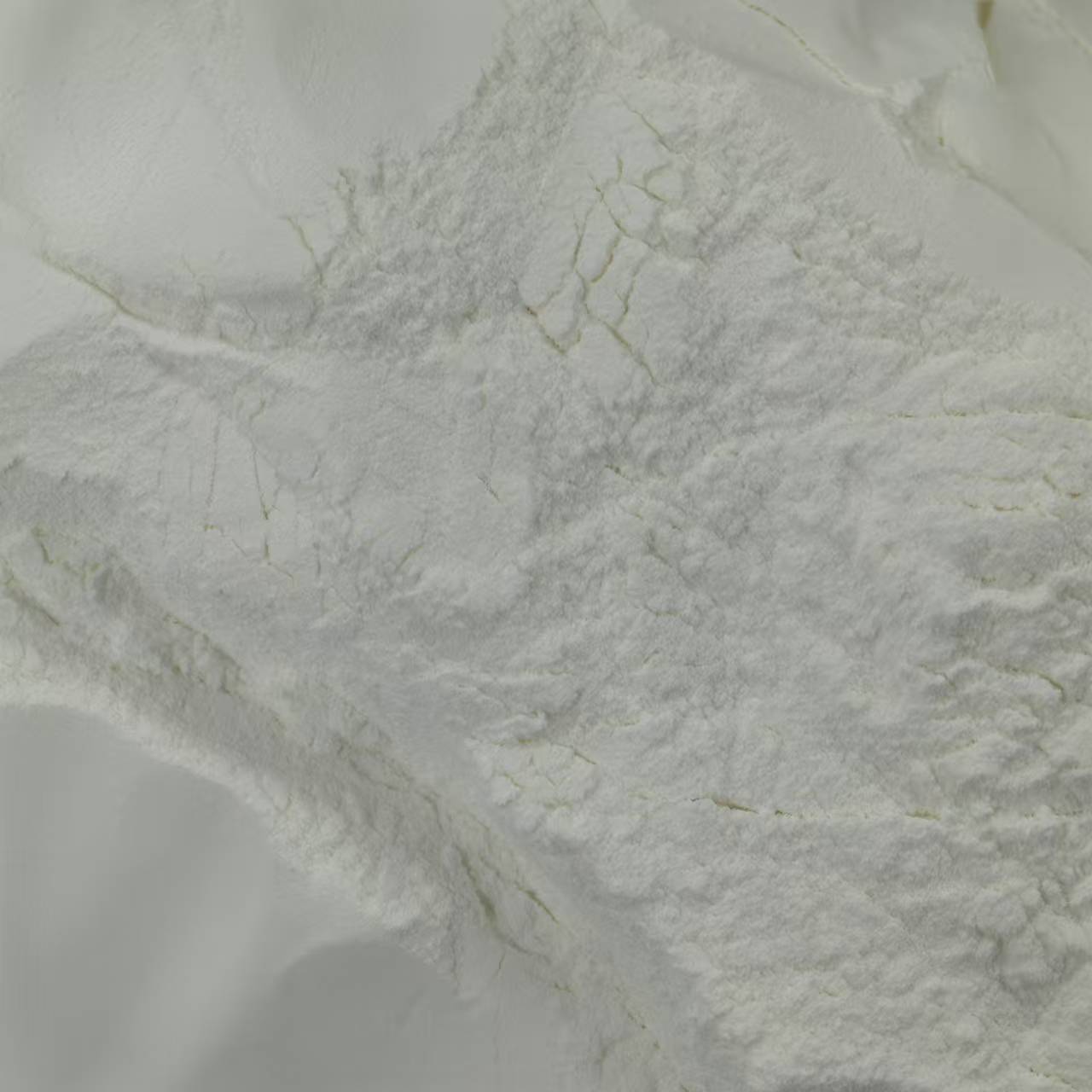

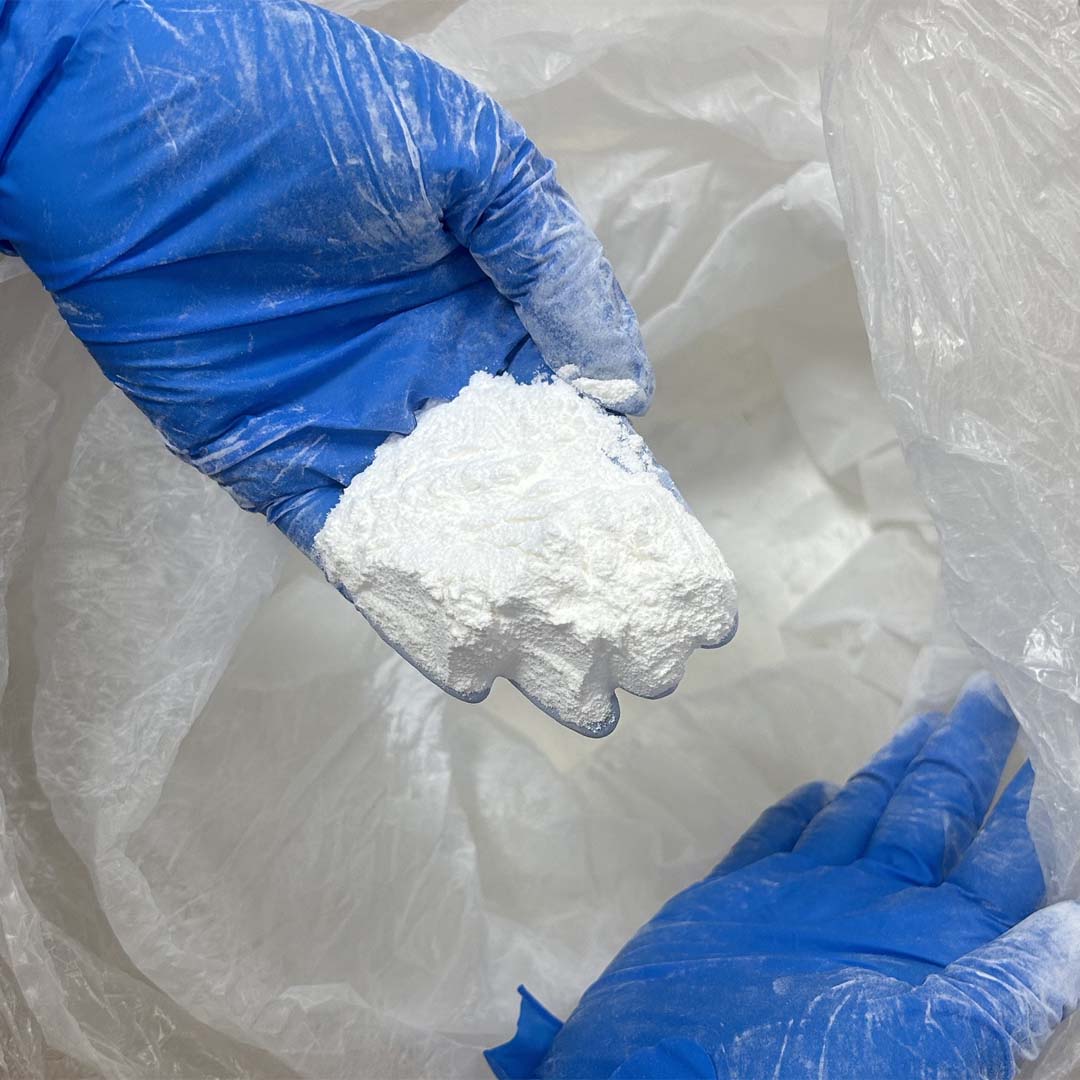

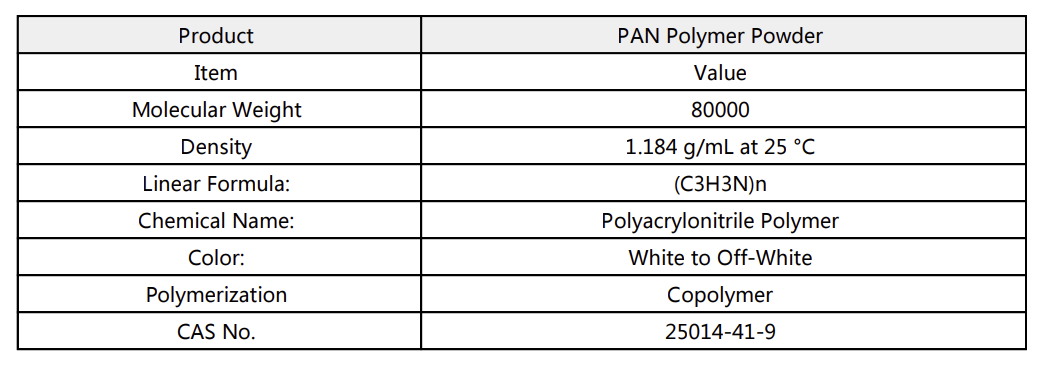

Polyacrylonitrile based copolymer

- Code:TC-PAN-P80000

- Material:100% Polyacrylonitrile(PAN)

- Weight:80000 Molecular weight

- Function:Making PAN precursor

- Color:white

SEND INQUIRY

Technical Data Sheet

Know more about PAN Polymer

Copolymerized polyacrylonitrile-based polymers are polymers obtained by copolymerization of two or more monomers with acrylonitrile.

Here are some detailed information about it:

1. Selection of comonomers:

- Carboxyl-containing monomers: such as itaconic acid, acrylic acid, etc. The introduction of carboxyl groups can increase the hydrophilicity of the polymer, improve its solubility in aqueous solution and processing performance, and the carboxyl group can also react chemically with other substances to provide reaction sites for further functionalization of the polymer.

- Amide-containing monomers: such as acrylamide, etc. The presence of amide groups can enhance the hydrogen bonding of the polymer and improve the thermal stability and mechanical strength of the polymer.

- Other functional monomers: According to different needs, other monomers with special functions can be selected, such as sulfonic acid-containing monomers can improve the ion exchange performance of the polymer; fluorine-containing monomers can give the polymer excellent hydrophobicity and corrosion resistance, etc.

2. Synthesis method:

- Solution polymerization method: dissolve acrylonitrile and comonomers in an appropriate solvent, add initiator, and carry out polymerization at a certain temperature. This method can better control the reaction rate and molecular weight of the polymer, but it requires a large amount of solvent, and the subsequent solvent recovery and treatment are more complicated.

- Aqueous phase precipitation polymerization: With water as the medium, acrylonitrile and comonomers are polymerized under the action of an initiator. During the reaction, the polymer will precipitate from the aqueous phase. This method has the advantages of simple operation, low cost, and environmental protection, but the molecular weight and structure of the polymer are relatively difficult to control.

- Mixed solvent polymerization: Combining the advantages of solution polymerization and precipitation polymerization, a mixed solvent of water and organic solvent is used as the reaction medium. This method can control the molecular weight and structure of the polymer to a certain extent, while reducing the amount of solvent used and the difficulty of recovery.

3. Performance characteristics:

- Physical properties: Compared with homopolymerized polyacrylonitrile, the physical properties of copolymerized polyacrylonitrile-based polymers such as solubility, flexibility, and processability are usually improved. For example, the introduction of a comonomer with a flexible chain segment can increase the flexibility of the polymer, making it easier to process into products of various shapes.

- Chemical properties: The introduction of comonomers can change the chemical properties of polymers, such as increasing the hydrophilicity, ion exchange properties, and antioxidant properties of polymers. For example, copolymerized polyacrylonitrile-based polymers containing sulfonic acid groups have good ion exchange properties and can be used in ion exchange membranes and other fields.

- Thermal properties: The structure and content of comonomers will affect the thermal stability of polymers. Generally speaking, the appropriate introduction of comonomers can improve the thermal stability of polymers, but if the thermal stability of comonomers is poor, it may reduce the thermal stability of polymers.

4. Application areas:

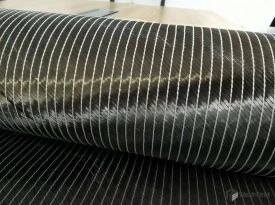

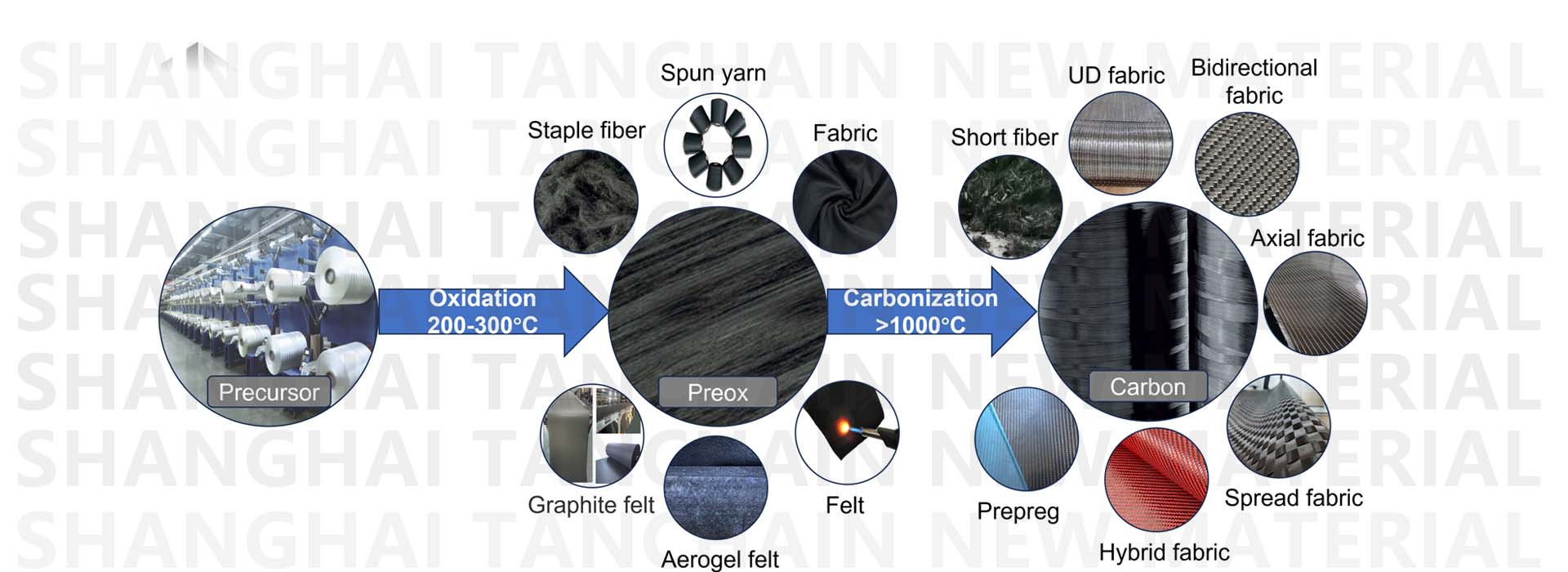

- Fiber materials: can be used to make high-performance fibers, such as precursors of carbon fibers. By selecting appropriate comonomers and polymerization processes, the strength, flexibility and thermal stability of polyacrylonitrile-based fibers can be improved, thereby preparing carbon fibers with excellent performance.

- Adsorption materials: using its rich functional groups and porous structure, it can be used to adsorb heavy metal ions, organic pollutants, etc., and has important application value in wastewater treatment, environmental remediation and other fields.

- Battery materials: in lithium-ion batteries, fuel cells and other fields, copolymerized polyacrylonitrile-based polymers can be used as electrode materials, electrolyte materials, etc., with good electrochemical properties and stability.

- Membrane materials: can be used to prepare ultrafiltration membranes, reverse osmosis membranes, gas separation membranes, etc., with good separation performance and selectivity.

Tanchain's Production Flow

SHIPPING

Q1:Are you a factory? Where are you located?

A: We are a professional manufacturer with more than 5 years production experience of composite materials, We have two factories, one in Nantong, Jiangsu, China and the other in Bangkok, Thailand.

Q2:What's the MOQ?

A: Usually 100SQM.

Q3:Package & Shipping.

A: Normal package: by carton.

Q4:When can we offer?

A: We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price pls call us or send email to us, so that we can reply you with priority.

Q5:How do you charge the sample fees?

A: If you need a samples from our stock, we can provide to you for free, but the free charge should be on your side. If you need a special size, We will charge the sample making fee which will be refund when you place an order.

Q6:What's your delivery time for production?

A:If we have stock , can delivery in 1-7 days, if without stock, need 5-30 days, depend on quantity.

Q7:What is your payment term?

A: Paypal, T/T, L/C AT sight, D/P and Western Union