-

-

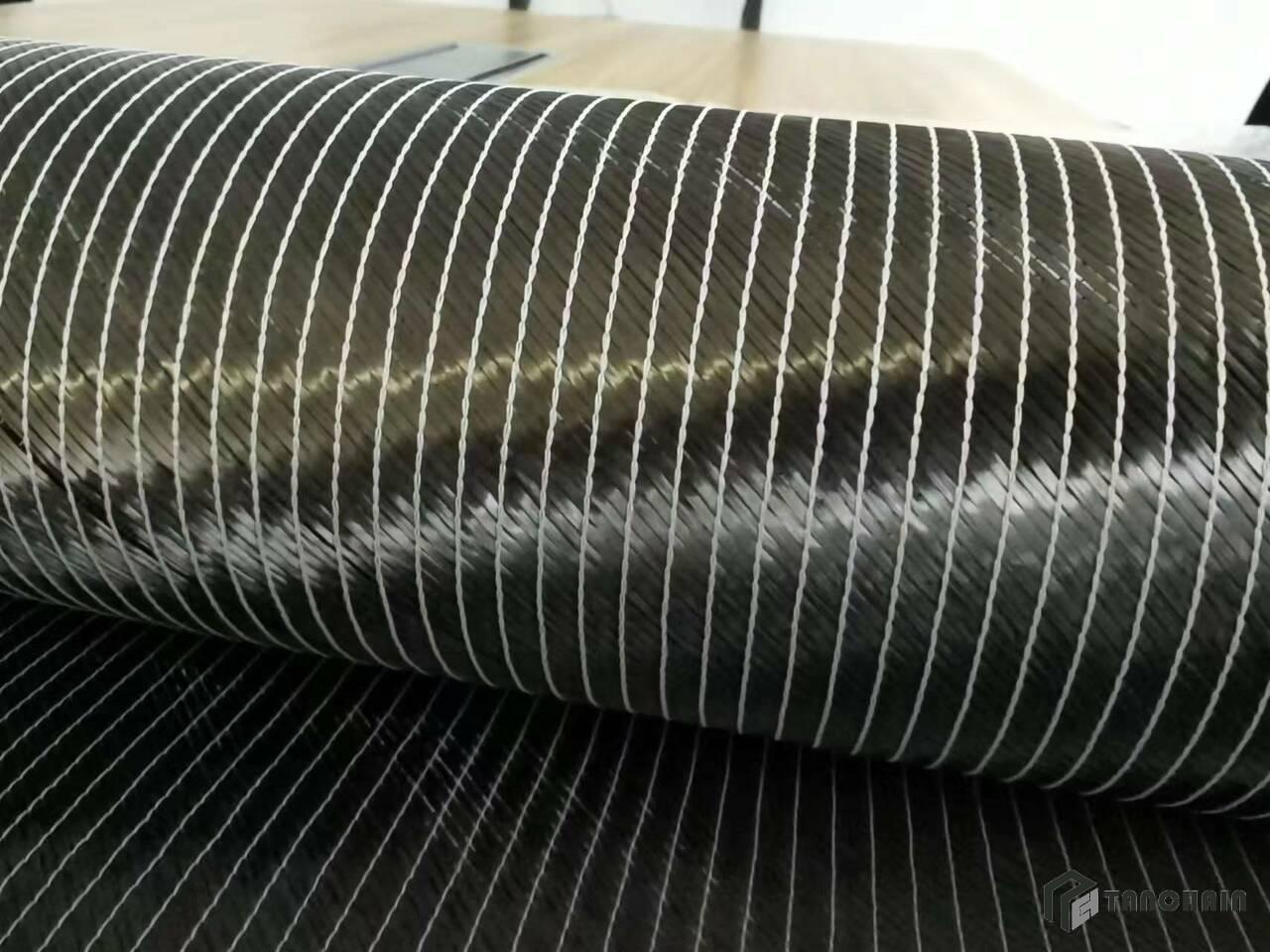

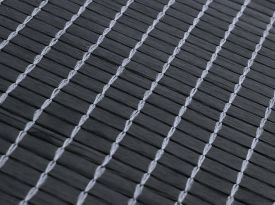

300gsm - Biaxial carbon fiber fabric - +45/-45 Non-Crimp - 9oz

- Code:TC-CF-X300B

- Material:12K carbon fiber

- Weight:300gram

- Function:Reinforcement

- Weave:Biaxial,multi-axial,triaxial,Non-Crimp

- Width:127cm 254cm

SEND INQUIRY

Parameters of bi-axial carbon fabric

| Product | 300gsm biaxial carbon fabric | |

| Item | Unit | Result |

| Gram weight | g/m² | 300 |

| Width | mm | 1270 |

| Thickness | mm | 0.45mm±0.04 |

| Pattern | +45/-45 | |

| Fiber Density(+45°) | /cm |

5.5 |

| Fiber Density(-45°) | /cm | 5.5 |

| Carbon fiber materials | K | 12K, T400 |

| Breaking strength | Mpa | 4000-4500 |

| Modulus | Gpa | >235 |

Product description:

The following is an analysis of various aspects of 300g ±45° biaxial carbon fiber fabric:

Performance indicators

- High strength: It has high tensile strength and can withstand large tensile forces. It can effectively enhance the bearing capacity of the structure in applications such as reinforcement.

- High elastic modulus: The elastic modulus is greater than 210Gpa, which makes it have good rigidity and not easy to deform.

- Low density: The carbon fiber density is 1.8g/cm³ and the weight is light. When used in aerospace, automotive and other fields, the weight of the structure can be reduced without reducing performance.

- Good durability: It has the characteristics of corrosion resistance and wear resistance, and is suitable for high acid, alkali, salt and atmospheric corrosion environments, and has a long service life.

- Certain elongation: The elongation is greater than 1.5%, and it has a certain flexibility and can adapt to the deformation of the structure to a certain extent.

Price advantage

- High cost performance: Compared with some carbon fiber fabrics with higher weight or special performance, the 300g fabric meets the performance requirements of most application scenarios while being relatively affordable and having a high cost performance.

- Cost control: In large-scale production and application, its relatively stable price helps enterprises control costs and improve economic benefits. For example, in the field of building reinforcement, it can reduce material costs while ensuring the reinforcement effect.

Application range

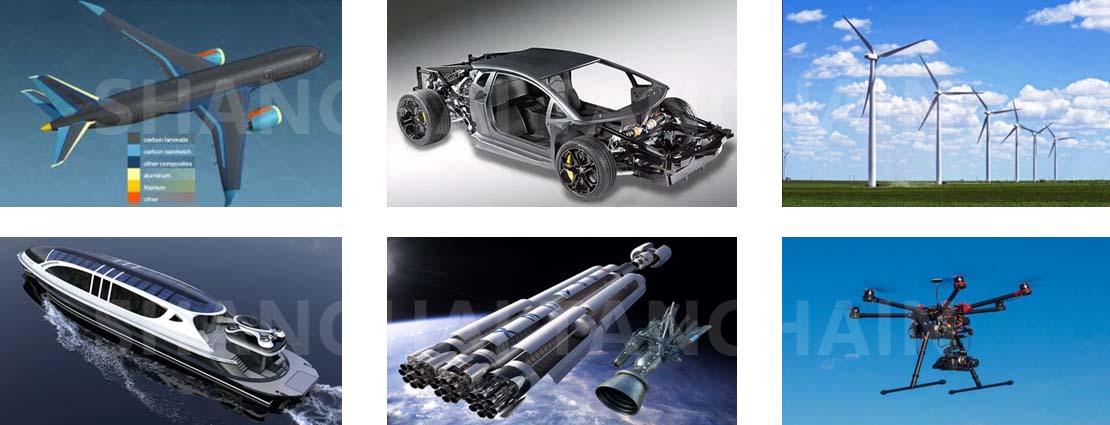

- Aerospace: Used to manufacture aircraft wings, fuselage structural parts, etc., which can reduce the weight of aircraft, improve fuel efficiency, and increase the range.

- Automobile manufacturing: It can be used to manufacture body, chassis, engine hood and other parts to improve the performance and safety of the car, while achieving lightweight design, reducing fuel consumption and exhaust emissions.

- Building reinforcement: It is widely used in the reinforcement and repair of beams, columns, plates and other structures of buildings, improving the seismic and wind resistance of the structure, and extending the service life of the building.

- Energy field: For example, in the manufacture of wind turbine blades, it can reduce the weight of the blades while ensuring the strength and stiffness of the blades, and improve the power generation efficiency; it can also be used to manufacture electrode materials for energy storage equipment, etc., to improve the performance of the equipment.

- Electronic equipment: It can be used to manufacture the shell and radiator of electronic products, etc., with good electromagnetic shielding and heat dissipation performance, while reducing the weight of the equipment.

- Sporting goods: such as bicycles, rackets, skis, etc., can improve the performance and use experience of products, and meet the needs of athletes and consumers for high-quality sporting goods.

Market prospects

- Demand growth: With the rapid development of industries such as aerospace and new energy vehicles, and the increasing demand for high-performance materials, the market demand for 300g ±45° biaxial carbon fiber fabrics will continue to grow.

- Technological progress: The continuous advancement of carbon fiber production technology will further improve the performance quality of the fabric, reduce production costs, enable it to be used in more fields, and expand market space.

- Policy support: The country's support for the new materials industry is constantly increasing. The introduction of relevant policies will provide strong guarantees for the development of 300g ±45° biaxial carbon fiber fabrics and promote their application in high-end manufacturing and other fields.

- Enhanced environmental awareness: Its lightweight characteristics are in line with the development trend of environmental protection and energy conservation, and play an important role in energy conservation and emission reduction in various industries, with broad market prospects.

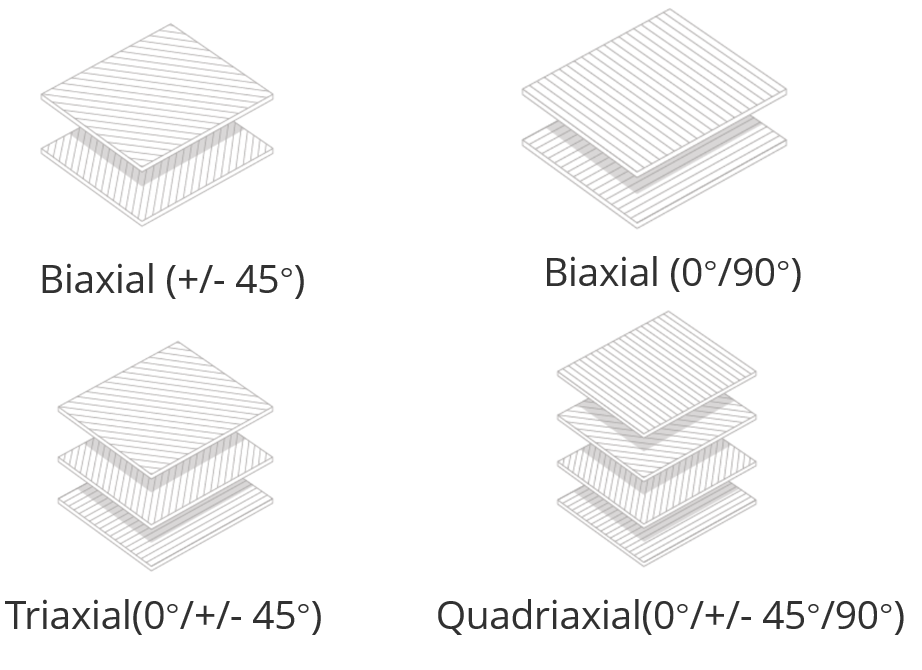

Properties of Axial carbon fabric

•Good Stability: Due to the fact that axial fabrics are a special structure formed by interweaving multi fiber tows, the structural stability of the fabric is good.

•Strength and stiffness in multiple orientations: The multidirectional arrangement of carbon fibers enables the strength and mechanical properties in all directions are the same. Designers and engineers can tailor the material’s properties according to specific load requirements, resulting in optimized structural performance.

Parameters of axial carbon fabric

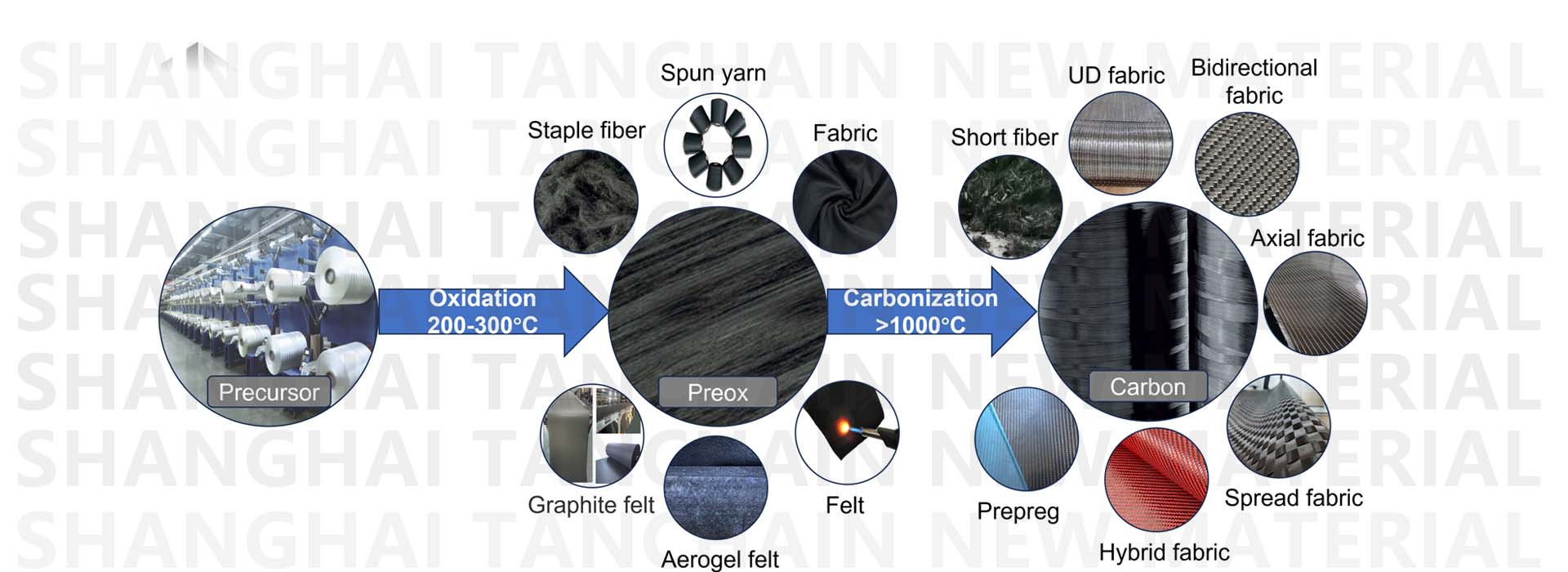

Tanchain's Production Flow

Product line for axial carbon fabric:

Shipping:

APPLICATIONS