-

-

1K - Pan precursor of carbon fiber

- Code:TC-PAN-1K

- Material:100% Polyacrylonitrile(PAN)

- Weight:1k filaments

- Function:The precusor of carbon fiber

- Color:white

SEND INQUIRY

There are many differences between 1k carbon fiber precursor and 3k carbon fiber precursor:

Number of monofilaments

- 1k carbon fiber precursor: Each bundle of carbon fiber precursor contains 1000 monofilaments.

- 3k carbon fiber precursor: Each bundle of carbon fiber precursor contains 3000 monofilaments, which is three times the number of monofilaments of 1k, and the fiber bundle is relatively thicker.

Performance

- Strength and modulus: Due to the small number of monofilaments, the strength and modulus of carbon fiber made from 1k carbon fiber precursor are higher under the same process and raw materials, which can better meet the needs of aerospace and other fields with extremely high material performance requirements.

- Flexibility: 3k carbon fiber precursor has relatively good flexibility and is more advantageous in some applications that require certain bending or folding performance, such as manufacturing certain carbon fiber products with complex shapes.

Production difficulty and cost

- Production difficulty: In the production process of 1k carbon fiber precursor, the control accuracy of process parameters is required to be higher, and the production difficulty is greater.

- Production cost: 1k carbon fiber precursor has high production difficulty, relatively low production efficiency, and high requirements for raw material quality, resulting in high production costs and higher prices.

Application fields

- 1k carbon fiber precursor: Mainly used in high-tech fields such as aerospace, national defense, such as manufacturing aircraft wings, fuselage structural parts, and missile bodies, etc., and also used in high-end sports products, such as professional bicycles, golf clubs, etc.

- 3k carbon fiber precursor: It has a wide range of applications. In addition to aerospace and defense fields, it is also commonly used in automobile manufacturing, electronic equipment, building reinforcement and other fields, such as manufacturing automobile body parts, engine hoods, and electronic product shells.

1k carbon fiber precursor has a high price, mainly for the following reasons:

High raw material cost

The main raw material for producing 1k carbon fiber precursor is high-grade polyacrylonitrile. Its preparation process is complicated and needs to meet the requirements of high regularity and high molecular weight. It involves complex stereoselective polymerization and chain transfer reactions and other unavoidable side reactions, which makes the raw material cost high.

Complex production process

The production process of 1k carbon fiber precursor includes polymerization, spinning, drawing, drying and densification, and other sections, and the control requirements for process parameters are extremely strict. For example, in the spinning process, although the dry-jet wet spinning process can produce high-quality 1k precursor, the process is slow and the single spindle line density is low, resulting in low production efficiency and increased costs.

Expensive production equipment

The production of carbon fiber precursor requires professional equipment, such as high-precision polymerization kettles, spinning machines, oxidation furnaces, carbonization furnaces, etc., and the research and development, manufacturing and maintenance costs of these equipment are very high. In addition, in order to ensure the continuity of production and the stability of product quality, the equipment needs to have high precision, high reliability, high temperature resistance, corrosion resistance and other properties, which further pushes up the purchase and operation costs of the equipment.

Strict quality requirements

1k carbon fiber precursor is mainly used in high-precision fields such as aerospace and national defense, and has extremely high requirements for its performance indicators such as strength, modulus, elongation, surface quality, and internal structure uniformity. In order to meet these quality standards, companies need to invest a lot of manpower, material resources and financial resources in raw material screening, production process control, quality testing, etc., thereby increasing production costs.

Market supply monopoly

The suppliers in the global carbon fiber precursor market are relatively concentrated, with high technical barriers, and it is difficult for new entrants to form large-scale production capacity in the short term. Market monopoly leads to insufficient supply and prices are easily raised.

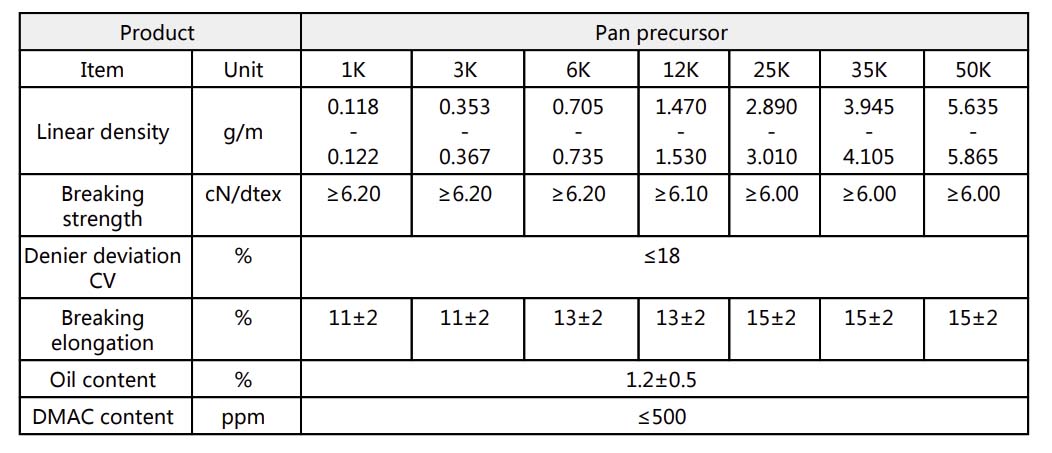

Technical Data Sheet

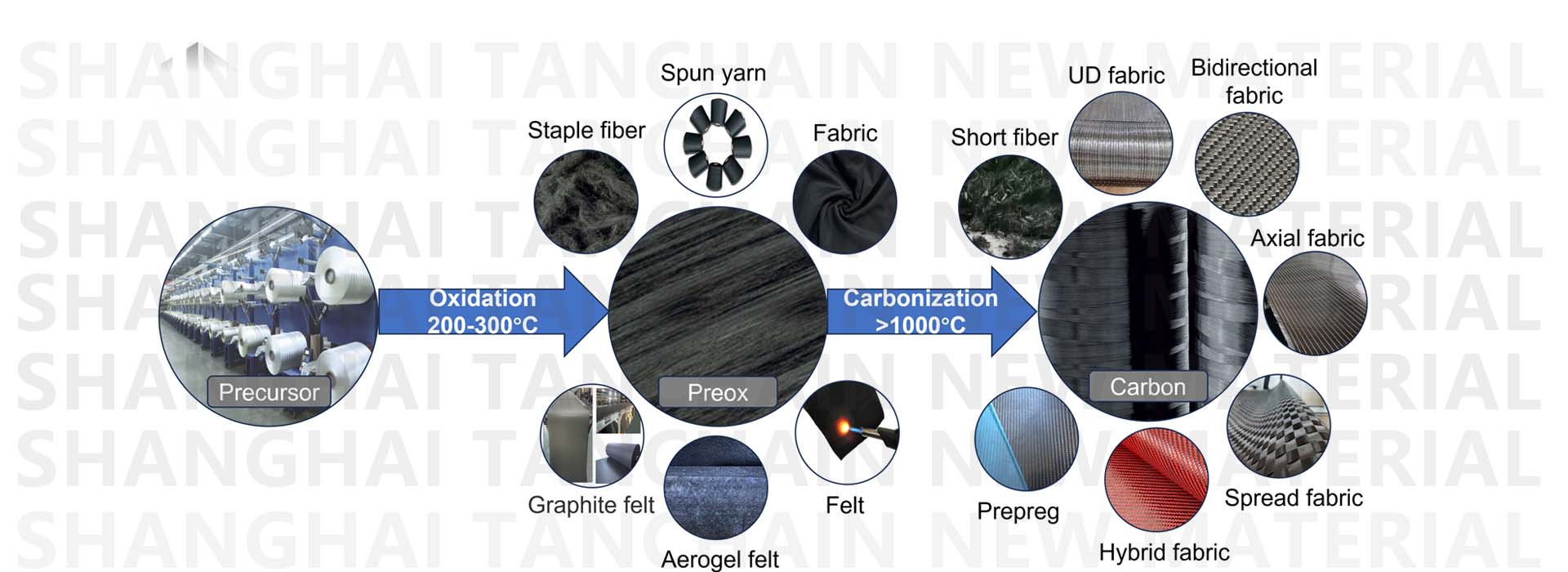

Tanchain's Production Flow

SHIPPING