-

-

50K - PAN precursor of carbon fiber

- Code:TC-PAN-50K

- Material:100% Polyacrylonitrile(PAN)

- Weight:50k filaments

- Function:The precusor of carbon fiber

- Color:white

SEND INQUIRY

Compared with 12k carbon fiber, 50k carbon fiber has the following advantages:

Cost and efficiency

- Low production cost: The large tow characteristics of 50k carbon fiber make it produce more in a unit time during the production process, thus reducing the production cost. However, due to the thinner tow, the production process requirements of 12k carbon fiber are more stringent, the production efficiency is relatively low, and the cost is also higher.

- High processing efficiency: During the processing of 50k carbon fiber, operations such as laying and impregnation are relatively faster, which can improve production efficiency, shorten production cycle, and reduce processing costs. It is especially suitable for large-scale production.

Application range

- Large structural parts manufacturing: 50k carbon fiber is more suitable for manufacturing large structural parts, such as wind turbine blades, automobile bodies, etc. Its large tow characteristics can better meet the requirements of large components for material dosage and performance, which can improve production efficiency, reduce costs, and ensure the overall performance of products.

- Wide application in the industrial field: Due to its cost advantage and good comprehensive performance, 50k carbon fiber is more widely used in the industrial field. It can be used to manufacture various parts and equipment in the chemical, electronic, mechanical and other industries, such as transmission shafts, pressure vessels, electronic equipment housings, etc.

The following are some major manufacturers of carbon fiber precursor:

Domestic manufacturers

- Zhongfu Shenying: Affiliated to China National Building Materials Group, it has a full set of independently developed international mainstream dry-jet wet-spinning high-performance carbon fiber precursor production lines and carbonization production lines. It is the first company in my country to overcome the difficulties of dry-jet wet-spinning technology, and its production capacity ranks among the top three in the world.

- Jilin Chemical Fiber: It has a complete industrial chain from precursor to carbon fiber to composite materials, and its production capacity is expanding rapidly. It is the global leader in carbon fiber precursor production capacity, and its production line has a high automation rate.

- Jilin Carbon Valley: It is the largest supplier of precursors in China. It is an affiliated enterprise with Jilin Chemical Fiber, and its products are mainly supplied to Jilin Chemical Fiber.

- Guangwei Composites: The leader of the entire carbon fiber industry, its business covers the entire industrial chain of carbon fiber precursor, carbon fiber, composite materials, etc., and it is the first A-share listed company in the domestic carbon fiber industry.

- Zhongjian Technology: The only company that focuses on the research and development and production of carbon fiber in the aerospace field and can achieve mass supply. Its product performance has reached the international leading level. It is an important supplier of ZT7 series carbon fiber products in the domestic aerospace field.

- Shanghai Petrochemical: A large state-owned enterprise with an existing raw silk production capacity of 15,000 tons/year and 7,500 tons/year of carbon fiber. It is building a 12,000-ton raw silk and 6,000-ton carbon fiber project, which is expected to be put into production in 2024.

Foreign manufacturers

- Japan Toray: A global giant in the carbon fiber industry, with leading technology, mature raw silk production technology, excellent product performance, and wide application in high-end fields such as aerospace and automobiles, occupying a large global market share.

- Japan Toho: It has rich experience and advanced technology in the production of carbon fiber raw silk, stable product quality, and its carbon fiber products have a high market share in the fields of industry and sporting goods.

- Mitsubishi Rayon: It has advanced production technology and equipment, and produces a wide variety of carbon fiber raw silk to meet the needs of different customers. It has strong competitiveness in the high-performance carbon fiber raw silk market.

- SGL: A well-known German manufacturer of carbon fiber raw silk and products. Its products are widely used in aerospace, energy and other fields, and are known for their high quality and high performance.

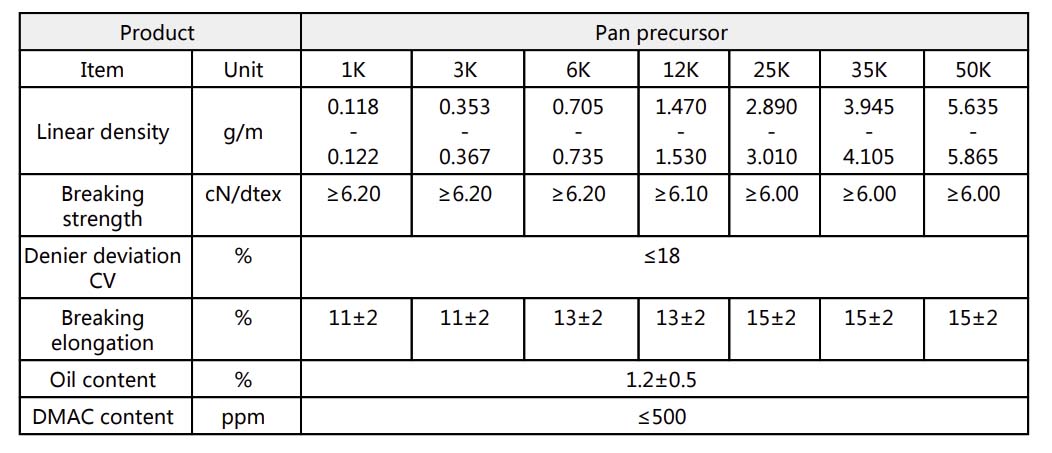

Technical Data Sheet

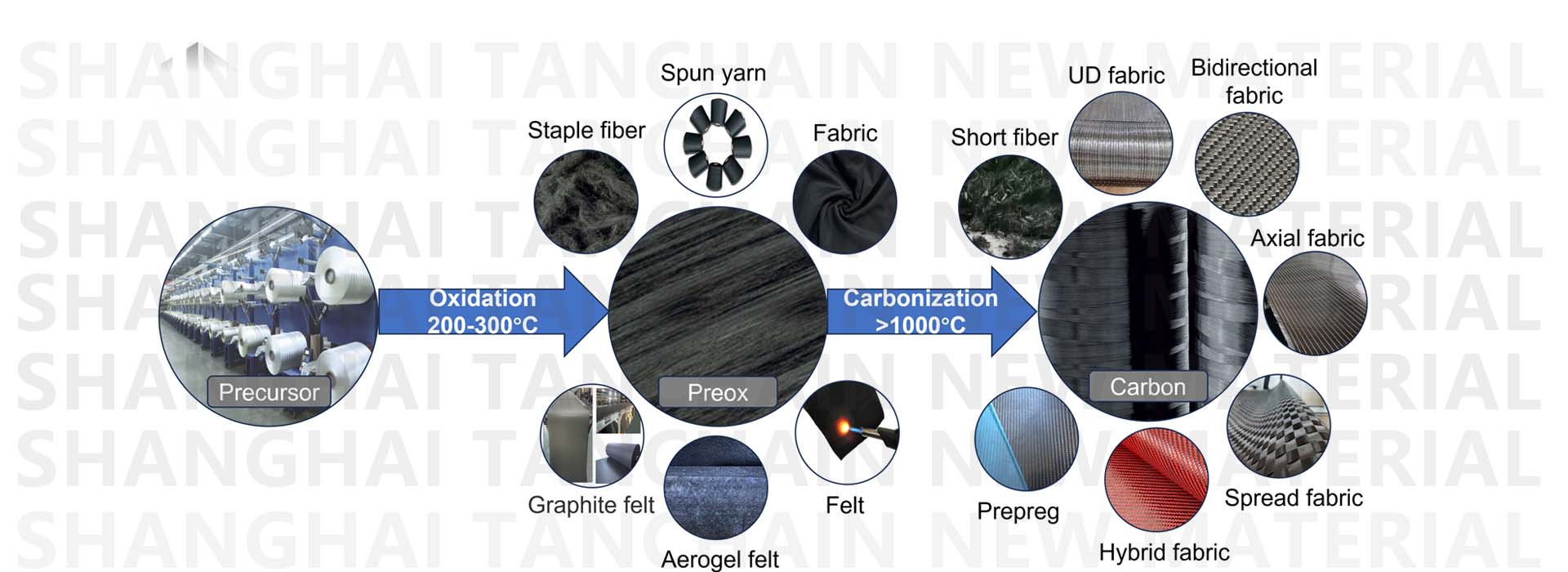

Tanchain's Production Flow

SHIPPING