-

-

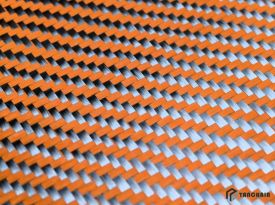

12K - 600gsm - Twill - Carbon Fabric - 18oz - high strength

- Code:TC-CF-12KC600TZ

- Material:100% Carbon Fiber

- Weight:600gsm

- Function:High strengh, Low weight, High modulus, good for reinforcement.

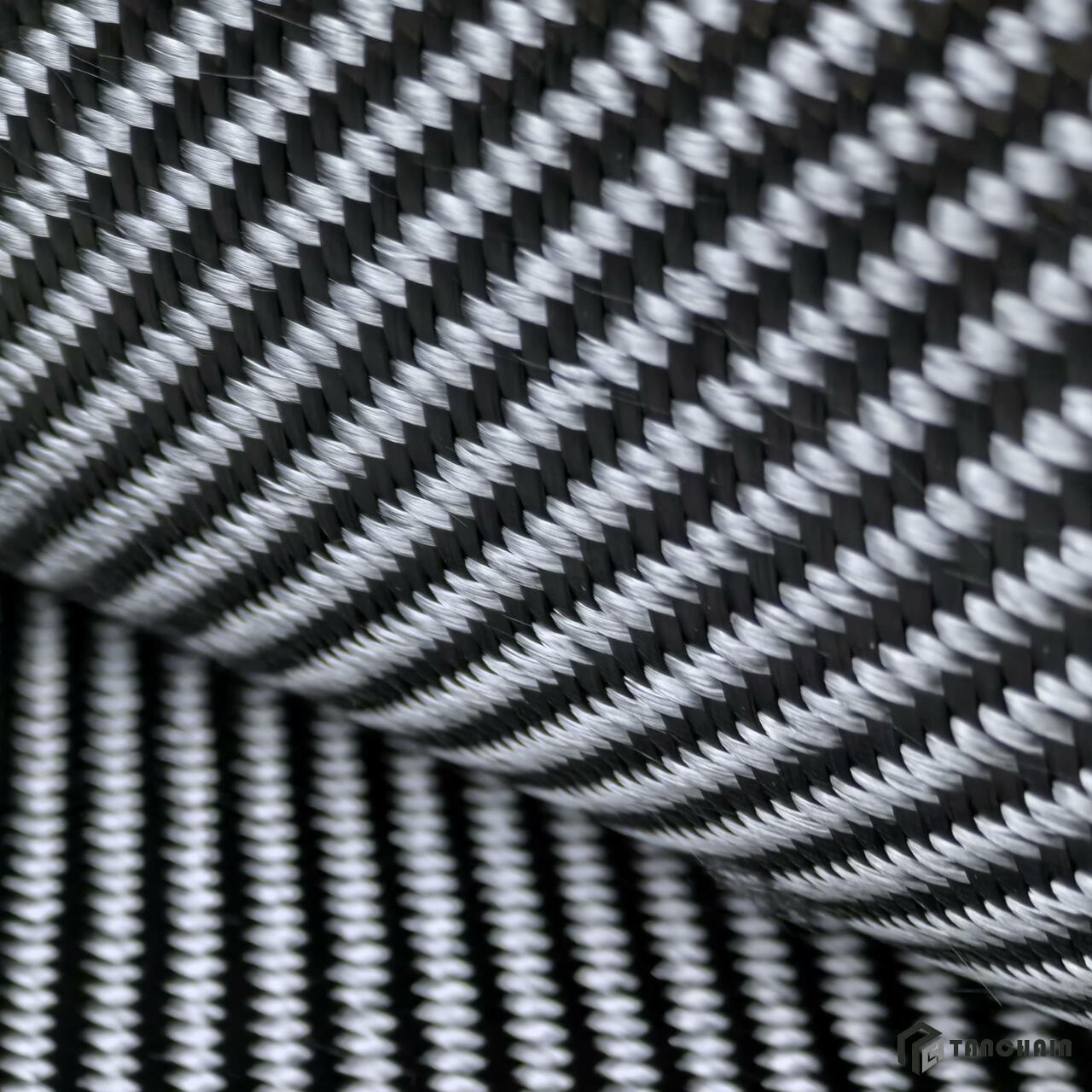

- Color:Black

- Weave:Twill

- Width:50-200cm

SEND INQUIRY

Material: |

100% carbon fiber | Yarn (warp): | 12k carbon fiber |

| Pattern: | Twill | Yarn (weft): | 12k carbon fiber |

| Weight : | 600gsm | Width: | 50-200cm |

| Density(warp): | 37.5/10cm | Thickness: | 0.90mm |

| Density(weft): | 37.5/10cm | Color: | Black |

Material: |

100% carbon fiber |

| Pattern: | Twill |

| Weight : | 600gsm |

| Density(warp): | 37.5/10cm |

| Density(weft): | 37.5/10cm |

| Yarn Count(warp): | 12k carbon fiber |

| Yarn Count(weft): | 12k carbon fiber |

| Width: | 50-200cm |

| Thickness: | 0.90mm |

| Color | Black |

Product Description

12K 600g twill high-strength carbon fiber fabric has the following characteristics and usage scenarios:

Characteristics

- High strength: Carbon fiber itself has high strength. The 600g weight and twill weaving method of this fabric further enhance its strength and can withstand greater tension and pressure.

- Lightweight: Carbon fiber material has low density, which can effectively reduce the weight of the product while ensuring strength, making it easy to carry and use.

- Good corrosion resistance: It has excellent corrosion resistance and can resist the erosion of chemicals such as acids and alkalis, and is suitable for harsh environments.

- Excellent wear resistance: The twill weave structure makes the fabric surface more wear-resistant, not easy to be scratched and worn, and extends the service life.

- Good fatigue resistance: Under repeated stress, it can still maintain good performance and is not prone to fatigue damage.

- Good thermal stability: It can maintain stable performance in high temperature environment and is not easy to deform or damage.

Usage scenario

- Aerospace field: Used to manufacture aircraft wings, fuselage structural parts, etc., which can reduce the weight of the aircraft and improve fuel efficiency and flight performance.

- Automotive industry: commonly used to manufacture car body shells, engine hoods, racing car frames, etc., which can reduce the weight of the car body while improving the safety and handling performance of the vehicle.

- Sports goods: such as bicycle frames, rackets, fishing rods, etc., which can make the products both lightweight and high-strength, improve the user experience and competitive performance.

- High-end electronic products: used to manufacture laptop shells, mobile phone shells, etc., which can protect internal components and make the products thinner and lighter.

- Industrial field: molds, fixtures, etc. can be made, and with its high strength and wear resistance, the precision and efficiency of industrial production can be improved.

- Medical equipment: such as wheelchairs, prostheses, etc., which can ensure strength and reduce weight, and improve the convenience and comfort of patients.

There are the following differences between 12K 600g twill high-strength carbon fiber fabric and 3K 200g twill carbon fiber fabric:

Appearance and texture

- 12K 600g twill: 12K means each bundle contains 12,000 fibers, the tow is thicker, and the woven twill texture is more atmospheric and rough.

- 3K 200g twill: 3K means each bundle has 3,000 fibers, and its twill texture is relatively delicate.

Physical properties

- Strength: Generally, the arrangement of single fibers in 3K carbon fiber tows is more regular, and the strength is relatively high. However, due to its high gram weight and twill structure, the overall strength of 12K 600g fabric can also meet many high-strength requirements.

- Weight: Under the same area, 12K 600g fabric is heavier, and 3K 200g fabric is lighter.

Processing difficulty

- 12K 600g twill: The fiber bundle is coarse, and the equipment and process requirements are special. It is difficult to manufacture complex shapes or fine parts.

- 3K 200g twill: Soft and delicate, easier to process and shape, suitable for making fine parts and products with high surface smoothness requirements.

Cost price

- 12K 600g twill: The production efficiency is relatively high, the single filament bundle is coarse and easy to process, and the cost may be low. However, due to the high gram weight and the possible use of special weaving technology, the overall cost will not be too low.

- 3K 200g twill: During the production process, the small filament fiber is processed more finely, the cost is higher, and the price is usually more expensive.

Usage scenario

- 12K 600g twill: It is often used in large structural parts and occasions where the appearance texture is not high but high strength is required, such as building reinforcement, large equipment housing, heavy machinery parts, etc.

- 3K 200g twill: widely used in aerospace, high-end sporting goods, high-performance automotive parts, electronic product casings and other fields, such as some small structural parts of aircraft, high-end bicycle frames, mobile phone casings, etc.

| Content: | 100% carbon fiber |

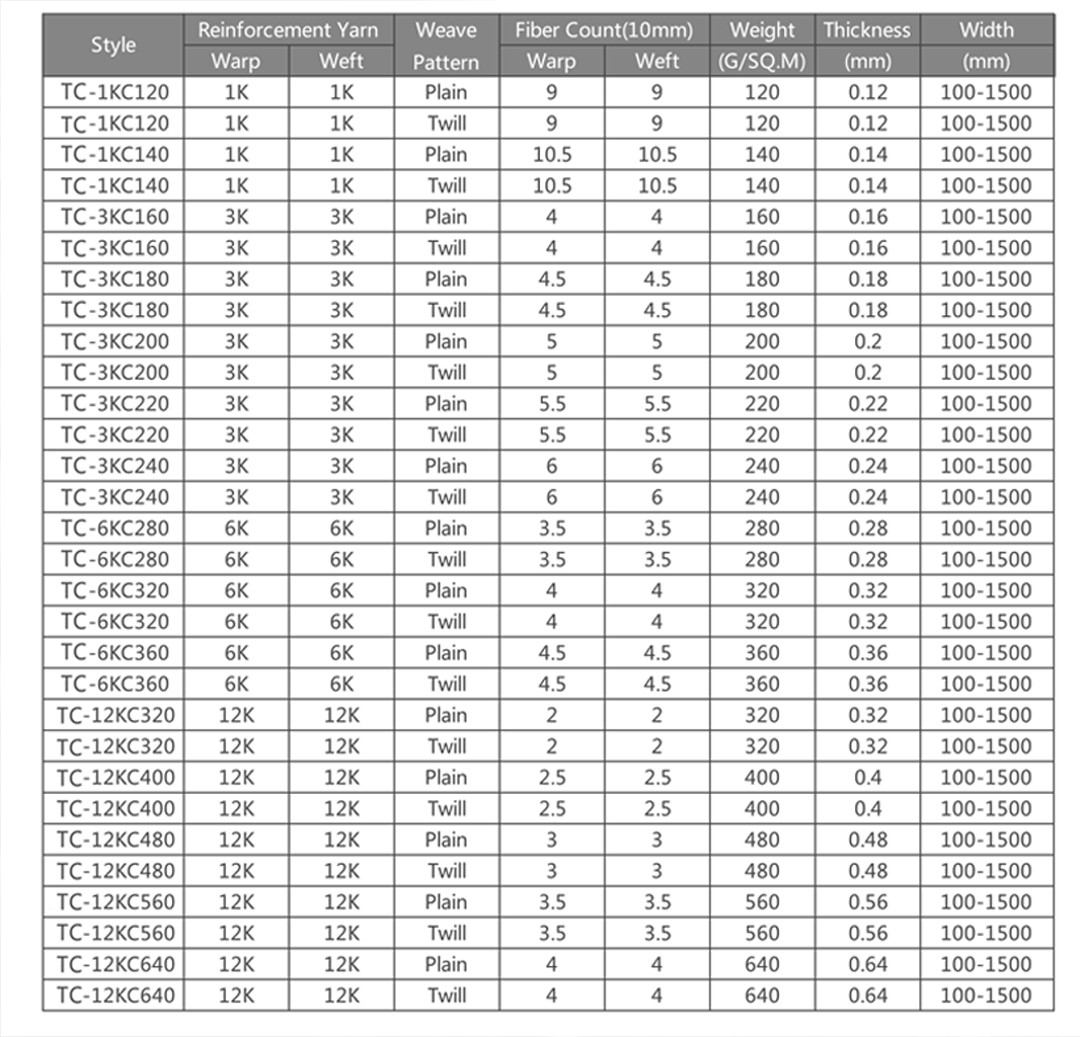

| Specification : | 1k-12k, 80-640gsm |

| Color: | Black |

| width: | 50-200cm, customized width is available |

| Feature: | High tensile strength, high modulus, strong durability and corrosion resistance, low thermal expansion, high impact resistance, conductivity |

| MOQ: | 100m |

| Meet standard : | AATCC/ASTM, EN, ISO, GB, AS |

| Application : | Used in car, trains, transportation, building reinforcement, sports equipment, aerospace |

Similar Series Technical Data