-

Preoxidized fibers important applications in the field of flame-retardant curtains

-

Preoxidized fibers and their blended yarns and fabrics have important applications in the field of flame-retardant curtains

Preoxidized fibers and their blended yarns and fabrics have important applications in the field of flame-retardant curtains, as follows:

1. Application of preoxidized fibers in the field of flame-retardant curtains:

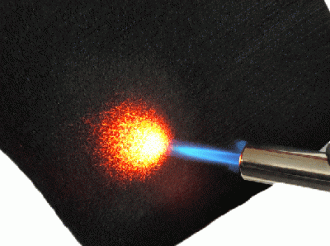

- Excellent flame retardant properties: Preoxidized fibers can maintain stable performance in high temperature environments, will not burn or melt when exposed to heat or fire, and can effectively prevent the spread of flames. Applying them to curtains can delay the spread of fire in the early stages of a fire, buying precious time for personnel evacuation and fire rescue.

- Good thermal stability: Preoxidized fibers have good dimensional stability at high temperatures and are not easy to deform, shrink or soften. This allows curtains made of preoxidized fibers to maintain a good shape in the face of high temperature environments of fires, and continue to play a role in blocking flames and smoke.

- High strength: Preoxidized fibers have high strength and can withstand certain external forces, such as collisions with objects and airflow shocks that may be encountered at the scene of a fire. They are not easy to break, ensuring the integrity and functionality of the curtains.

2. Application of pre-oxidized fiber blended yarn in the field of flame-retardant curtains:

- Blending with other fibers to improve performance: Pre-oxidized fibers can be blended with other fibers such as flame-retardant viscose, aramid, etc. For example, after blending with flame-retardant viscose, the advantages of both can be combined to improve the spinnability and processing performance of pre-oxidized fibers while maintaining good flame-retardant properties, thereby reducing costs. Blended yarns can also improve the strength and durability of curtain fabrics, making them more suitable for daily use.

- Rich product selection: Through different blending ratios and spinning processes, blended yarns of various specifications can be produced to meet the needs of different types of curtains, such as light and thin window screens, heavy blackout curtains, etc.

3. Application of pre-oxidized fiber fabrics in the field of flame-retardant curtains:

- Functional composite fabrics: Pre-oxidized fiber fabrics can be composited with other functional fabrics, such as anti-ultraviolet fabrics, heat-insulating fabrics, etc., to make flame-retardant curtains with multiple functions. This composite fabric not only has excellent flame-retardant properties, but also can effectively block ultraviolet rays, reduce heat transfer, and improve indoor comfort.

- Special structure design: Using the characteristics of pre-oxidized fiber fabrics, curtains with special structures can be designed, such as curtains with multi-layer structures. Among them, the pre-oxidized fiber fabric is used as the middle fireproof layer, and the outer layer can be made of ordinary decorative fabrics, which not only ensures the beauty of the curtains, but also improves their flame retardant properties.

- Industrial and public building applications: In public buildings such as industrial plants, warehouses, shopping malls, hotels, and hospitals, the flame retardant properties of curtains are required to be high. Flame-retardant curtains made of pre-oxidized fiber fabrics can meet the fire safety needs of these places and reduce the risk of fire.