-

-

550GSM,Pre-Oxidized PAN fabric - Panox Fabric - Flame Retardant Fabric

- Code:TC-OPF550

- Material:100% Pre-Oxidized PAN Fiber

- Weight:550GSM

- Function:Fireproof clothing, Steelmaking clothing, Welder unifrom, Welding blanket

- Color:Black

- Width:150CM

SEND INQUIRY

Product Description

Unveiling the Superiority of 550g High - Density Polyacrylonitrile - based Flame - Retardant Pre - oxidized Fiber Fabrics

In the dynamic field of material science, high - performance fabrics are constantly being developed to meet the ever - increasing demands of various industries. Among these, 550g high - density polyacrylonitrile - based flame - retardant pre - oxidized fiber fabrics stand out as a remarkable innovation, offering a unique set of characteristics, versatile application scenarios, and distinct advantages over other flame - retardant fabrics.

I. Distinctive Characteristics

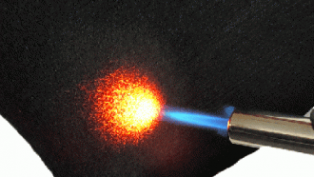

A. Exceptional Flame - Retardant Performance

The most prominent feature of these fabrics is their outstanding flame - retardant ability. With an extremely high limiting oxygen index (LOI), often ranging from 40% to 60%, they are highly resistant to combustion. When exposed to flames, they do not burn, melt, or drip, effectively preventing the spread of fire. Instead, they form a stable char layer on the surface, which acts as a barrier, protecting the underlying material from further heat and flame penetration. This property is crucial in ensuring the safety of people and property in high - risk environments.

B. Excellent Thermal Insulation

These fabrics exhibit remarkable thermal insulation properties. They can withstand high temperatures, ranging from 300℃ to 1000℃, depending on the specific application and processing conditions. Their low thermal conductivity means that they can effectively block the transfer of heat, making them ideal for applications where heat protection is essential. Whether it is in industrial furnaces, fire - fighting operations, or aerospace applications, this high - temperature resistance ensures the reliability and durability of products made from these fabrics.

C. Robust Mechanical Properties

Despite their high - performance fire - and heat - resistant characteristics, 550g high - density polyacrylonitrile - based pre - oxidized fiber fabrics possess excellent mechanical properties. They have high strength and modulus, providing the fabric with good tear resistance and abrasion resistance. This allows the fabric to maintain its structural integrity even under harsh mechanical stress, whether it is during normal use or in extreme conditions. The fabric's flexibility also ensures that it can be easily shaped and sewn into various products without compromising its performance.

D. Chemical Stability

These fabrics show high chemical stability, being resistant to a wide range of chemical substances, including acids and alkalis. This property makes them suitable for use in chemical processing plants, laboratories, and other industrial settings where exposure to corrosive chemicals is common. The fabric's ability to withstand chemical attacks ensures its long - term durability and reliability in such harsh chemical environments.

E. Good Processability

In addition to their functional properties, these fabrics offer good processability. They can be easily spun, woven, knitted, needled, and sewn using standard textile manufacturing techniques. This makes it possible to produce a wide variety of products, from protective clothing to industrial insulation materials, with relative ease and efficiency.

II. Diverse Application Scenarios

A. Protective Apparel

In the field of personal protective equipment (PPE), these fabrics are widely used to manufacture fire - resistant clothing for firefighters, industrial workers in high - risk environments, and welders. The fabric's flame - retardant and heat - insulation properties ensure that the wearer is well - protected from heat and fire hazards. For example, firefighter suits made from this fabric can withstand the intense heat of a fire, allowing firefighters to perform their duties safely. The fabric's mechanical strength also ensures that the clothing can endure the rough handling and abrasion during rescue operations.

B. Building and Construction

In the construction industry, these fabrics are used in various applications to enhance fire safety and energy efficiency. They can be used as insulation materials in walls, roofs, and floors, providing both thermal insulation and fire protection. In the event of a fire, the fabric's flame - retardant properties can prevent the fire from spreading, giving occupants more time to evacuate. Additionally, the fabric's durability and chemical stability make it suitable for use in harsh building environments, ensuring long - term performance.

C. Industrial Machinery and Equipment

In industrial settings, these fabrics are used to protect machinery and equipment from heat and fire. For example, they can be used as insulation materials for industrial furnaces, boilers, and engines. The fabric's high - temperature resistance and thermal insulation properties help to improve the energy efficiency of these machines by reducing heat loss. Moreover, in case of an accidental fire, the fabric can prevent the fire from spreading to other parts of the equipment, minimizing damage and downtime.

D. Aerospace and Aviation

In the aerospace and aviation industries, where safety and reliability are of utmost importance, these fabrics find applications in aircraft interiors, engine compartments, and rocket components. The fabric's flame - retardant, heat - resistant, and lightweight properties make it an ideal choice for these applications. For example, in aircraft interiors, the use of these fabrics can reduce the risk of fire and improve passenger safety. In engine compartments, the fabric can protect the engine from heat and fire, ensuring the smooth operation of the aircraft.

III. Advantages over Other Flame - Retardant Fabrics

A. Cost - Effectiveness

Compared to some high - performance flame - retardant fabrics such as aramid fibers, 550g high - density polyacrylonitrile - based pre - oxidized fiber fabrics offer a more cost - effective solution. While providing similar levels of flame - retardant and heat - resistant performance, they are generally more affordable, making them an attractive option for industries with cost - sensitive applications. This cost - effectiveness does not come at the expense of quality, as these fabrics still meet high - standards of performance and durability.

B. Superior Thermal Insulation

When compared to many traditional flame - retardant fabrics, these polyacrylonitrile - based pre - oxidized fiber fabrics have a lower thermal conductivity, which means they offer better heat - insulation performance. This allows them to provide more effective protection against high - temperature environments, making them a preferred choice in applications where heat protection is critical, such as in industrial furnaces and fire - fighting equipment.

C. Easier Processing

Compared to some complex flame - retardant fabrics, such as certain types of inorganic fiber - based materials, the polyacrylonitrile - based pre - oxidized fiber fabrics are more easily processed using standard textile manufacturing techniques. This simplifies the production process, reduces production costs, and enables the manufacture of a wider variety of products with different shapes and sizes.

In conclusion, 550g high - density polyacrylonitrile - based flame - retardant pre - oxidized fiber fabrics offer a combination of outstanding characteristics, diverse application scenarios, and significant advantages over other flame - retardant fabrics. Their unique properties make them an invaluable material in a wide range of industries, contributing to enhanced safety, improved performance, and cost - effective solutions. As technology continues to advance, these fabrics are likely to play an even more important role in the development of high - performance materials.

Material: |

100% pre-oxidized pan fiber | Yarn Count: | 8-10S |

| Pattern: | Woven | Weight : | 550gsm |

| Color: |

Black | Width: | 150cm |

Material: |

100% pre-oxidized pan fiber |

| Pattern: | Woven |

| Yarn Count: | 8-10S |

| Color: | Black |

| Width: |

150CM |

| Weight: | 550GSM |

Company Information

Shanghai Tanchain New Material Technology Co., Ltd is a high-tech enterprise focused on developing, producing, and marketing technical textiles products and composite materials, for the industrial, transportation, automotive, and protective industries. We have more than 8 years' experience in producing innovative products for extremely protective and labor protective applications,and with our great advantage in sourcing and technology, Tanchain has grown to be one of the leading suppliers in Chinese technical textiles market. We have a complete industrial chain and a strict quality management system.

Tanchain carefully selected raw material suppliers from dozens of first-class raw material suppliers domestically and overseas, and has signed long-term supply agreements, which ensures that we have large quantities of the best quality raw materials on a timely basis, and it is also a fundamental guarantee of the quality of our company's products.

We have built high-standard modern factories domestically and overseas, and have hired managers and technicians with first-class work experience in domestic and foreign companies, so as to ensure that our products have our own technical advantages and market competitiveness.

Good products allow us to obtain a large number of customers in domestic and overseas markets, and these high-quality customers are our company's valuable resources. Excellent customer groups give us information feedback while improving the function and quality of our products.

The quality control department has been established since the beginning of the company, and the chairman of the company attaches great importance to quality control. We have invested a huge amount of money to ensure the quality of products, which is the basis for our long-term foothold in the market. The factory manages and controls the whole process from raw materials into the factory, production and processing to finished products, and each process follows scientific norms in order for continuous improvement.

Our mission is to be recognized as a premier supplier to the markets we serve by providing quality yarns, fabrics and other textile products to satisfy the needs of our customers. Our mission will be accomplished through excellence in customer service, sales and manufacturing, and supported by teamwork of all associates. We will continue our tradition of honesty, fairness and integrity in the relationships with our customers, associates, community and stakeholders.