-

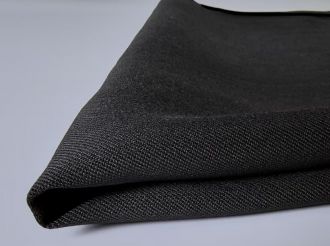

Graphite fabric used for all-vanadium flow batteries

-

Graphite fabric has good conductivity and can provide efficient electron transmission channels for the electrochemical reaction of all-vanadium flow batteries

Our graphite fabric is made from PAN pre-oxidized fibers through a complex process.

First, the pre-oxidized fibers are curled and cut, and then made into yarns through a ring spinning process. The yarns are then woven into fabrics through a shuttle weaving process. After the fabrics are carbonized and graphitized, graphite fabrics are produced.

Application

- Graphite fabric has good conductivity and can provide efficient electron transmission channels for the electrochemical reaction of all-vanadium flow batteries. For example, during charging and discharging, it can ensure the smooth transfer of electrons between the electrode and the external circuit.

- Its high porosity and large specific surface area can fully penetrate and contact the electrolyte, greatly increasing the reaction active sites, thereby improving the battery's charging and discharging efficiency and power density.

- Graphite fabric also has good chemical stability and corrosion resistance, and can work stably in the acid electrolyte of all-vanadium flow batteries for a long time, extending the service life of the electrodes.

Development prospects

- With the advancement of the dual carbon goals, the demand for grid-connected new energy such as wind power and solar energy has increased. As an energy storage device, all-vanadium flow batteries have ushered in development opportunities, which will drive the growth of graphite fabric market demand.

- Compared with graphite felt, the thickness of graphite fabric is significantly reduced, which saves space, further improves its performance and reduces costs. It is of great significance to promote the commercial application of all-vanadium flow batteries and expand their market share in power grid peak regulation, UPS power supply and other fields.

Technical route

- Modification treatment: The surface of graphite fabric is treated by high-temperature oxidation, electrochemical oxidation, strong acid oxidation and other methods to introduce oxygen-containing functional groups to improve its hydrophilicity and electrochemical activity; doping modification is adopted, such as doping metals, non-metallic elements or compounds, to improve the conductivity and catalytic performance of graphite fabric.

- Loading catalyst: Loading highly active catalysts on the surface of graphite fabric, such as bismuth single atom loaded graphite fabric electrode developed by Dalian Institute of Chemical Physics, can significantly improve the reaction rate and power density of the battery.

- Optimizing preparation process: Improving the preparation process of graphite fabric, such as using special raw materials, optimizing carbonization and graphitization temperature, time and other parameters, to improve the quality and performance of graphite fabric; developing new preparation methods, such as plasma treatment, microwave-assisted synthesis, etc., to reduce costs and improve production efficiency.