-

-

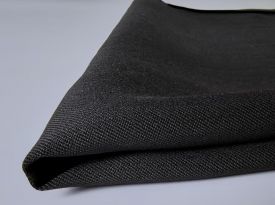

280GSM,Pre-Oxidized PAN fabric - Panox Fabric - Kevlar hybrid fabric - Flame Retardant Fabric

- Code:TC-OPF280

- Material:Pre-Oxidized PAN Fiber and Kevlar fiber

- Weight:280GSM

- Function:Fireproof clothing, Steelmaking clothing, Welder unifrom, Welding blanket

- Color:Black

- Width:150CM

SEND INQUIRY

Product Description

Unraveling the Excellence of 280 - gram Polyacrylonitrile - based Pre - oxidized Fiber and KEVLAR Blended Flame - Retardant Fabrics

In the domain of high - performance textiles, the development of advanced flame - retardant fabrics has been a continuous pursuit to meet the stringent safety and functionality requirements across various industries. The 280 - gram polyacrylonitrile - based pre - oxidized fiber and KEVLAR blended flame - retardant fabric represents a remarkable innovation, combining the best of two high - performing materials to offer a unique set of characteristics, versatile application scenarios, and distinct advantages.

I. Distinctive Characteristics

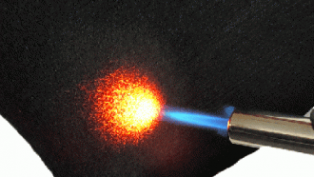

A. Superior Flame - Retardant Performance

The blend of polyacrylonitrile - based pre - oxidized fiber and KEVLAR results in a fabric with outstanding flame - retardant properties. Polyacrylonitrile - based pre - oxidized fibers have a high limiting oxygen index (LOI), typically ranging from 35% - 50%, and KEVLAR, renowned for its excellent fire - resistant qualities, further elevates the fabric's flame - retardant capabilities. When exposed to flames, the fabric forms a stable char layer, preventing the spread of fire. It does not melt or drip, reducing the risk of secondary burns, and provides reliable protection in high - risk fire environments.

B. Exceptional Mechanical Strength

KEVLAR is well - known for its high tensile strength, and when blended with polyacrylonitrile - based pre - oxidized fiber, the resulting fabric inherits this strength advantage. The fabric can withstand significant mechanical stress, including tearing, abrasion, and puncture. This makes it suitable for applications where durability is crucial. Whether it is used in protective gear that may be subject to rough handling or in industrial settings with constant wear and tear, the fabric's robust mechanical properties ensure its long - term performance.

C. Thermal Stability

Both polyacrylonitrile - based pre - oxidized fiber and KEVLAR exhibit good thermal stability. The blended fabric can endure high temperatures without significant degradation of its properties. It can resist heat up to a certain threshold, depending on the specific blend ratio, and maintain its structural integrity. This thermal stability is vital in applications where exposure to heat is common, such as in industrial furnaces, welding operations, and fire - fighting scenarios.

D. Lightweight Nature

Weighing in at 280 grams, this blended fabric offers a relatively lightweight option compared to some other heavy - duty flame - retardant materials. The use of polyacrylonitrile - based pre - oxidized fiber, which has a relatively low density, contributes to the fabric's lightweight nature. This is an advantage in applications where mobility and ease of use are important, such as in personal protective equipment for firefighters or in applications where weight reduction can lead to improved efficiency, like in some aerospace components.

E. Good Chemical Resistance

The blend of these two materials also endows the fabric with good chemical resistance. It can withstand exposure to a variety of chemicals, including acids, alkalis, and solvents to a certain extent. This makes it suitable for use in industrial environments where chemical spills or corrosive substances are present, ensuring the fabric's durability and continued performance in such harsh conditions.

II. Diverse Application Scenarios

A. Protective Clothing

1. Firefighting

- Firefighters rely on high - quality protective gear to keep them safe in the face of intense heat and flames. The 280 - gram polyacrylonitrile - based pre - oxidized fiber and KEVLAR blended fabric is an ideal choice for firefighting suits. Its flame - retardant properties protect against direct fire exposure, while the high - strength and abrasion - resistant nature of the fabric can withstand the rough handling during rescue operations. The lightweight aspect also allows firefighters to move more freely, reducing fatigue during long - term operations.

2. Industrial Workers

- Workers in industries such as oil and gas, chemical manufacturing, and metalworking are often at risk of exposure to fire and heat. Protective clothing made from this blended fabric can safeguard them from potential hazards. In oil refineries, for example, where the risk of fire due to flammable substances is high, workers can wear coveralls made from this fabric to ensure their safety.

B. Aerospace Applications

1. Aircraft Interiors

- In aircraft, safety is of utmost importance. The blended fabric can be used in aircraft interiors, such as seat covers, wall linings, and curtains. Its flame - retardant properties reduce the risk of fire spreading in case of an onboard fire. The lightweight nature of the fabric also helps in reducing the overall weight of the aircraft, contributing to fuel efficiency.

2. Engine Compartments

- Engine compartments are exposed to high temperatures and potential fire hazards. The fabric can be used as insulation and protective material in engine compartments. Its thermal stability and flame - retardant properties protect the engine components from heat and potential fire, ensuring the smooth operation of the aircraft.

C. Automotive Industry

1. Car Interiors

- For car interiors, the fabric can be used in seat upholstery, floor mats, and interior trims. Its flame - retardant properties enhance the safety of passengers in case of a fire. The good mechanical strength ensures that the fabric can withstand the normal wear and tear in a car, and the chemical resistance protects it from common automotive fluids.

2. Industrial Vehicle Interiors

- In industrial vehicles like trucks, buses, and construction vehicles, the fabric can provide similar benefits. In construction vehicles, which are often used in dusty and harsh environments, the fabric's abrasion - resistant and flame - retardant properties make it a suitable choice for interior applications.

III. Key Advantages

A. Cost - Performance Balance

Compared to using pure KEVLAR, which is a high - cost material, the blend with polyacrylonitrile - based pre - oxidized fiber offers a more cost - effective solution. While maintaining a high level of performance in terms of flame - retardancy, strength, and thermal stability, the inclusion of the relatively more affordable polyacrylonitrile - based pre - oxidized fiber reduces the overall cost. This makes it accessible to a wider range of industries and applications.

B. Customizable Properties

The blend ratio of polyacrylonitrile - based pre - oxidized fiber and KEVLAR can be adjusted according to specific application requirements. If an application requires more emphasis on flame - retardancy, the proportion of polyacrylonitrile - based pre - oxidized fiber can be increased. On the other hand, if high - strength is the primary requirement, more KEVLAR can be incorporated. This flexibility allows for the customization of the fabric's properties to meet diverse industry needs.

C. Enhanced Comfort in Protective Gear

The lightweight nature of the 280 - gram fabric, combined with its good mechanical properties, contributes to enhanced comfort in protective gear. In firefighting suits, for example, the reduced weight makes it easier for firefighters to move around during operations. The fabric's flexibility also allows for a better fit, which is crucial for the wearer's comfort and mobility.

In conclusion, the 280 - gram polyacrylonitrile - based pre - oxidized fiber and KEVLAR blended flame - retardant fabric is a high - performance textile with a unique set of characteristics, wide - ranging application scenarios, and distinct advantages. Its combination of properties makes it a valuable material in various industries, ensuring safety, durability, and functionality. As industries continue to demand advanced materials, this blended fabric is well - positioned to play a significant role in meeting these requirements.

Material: |

Pre-oxidized pan fiber, Kevlar fiber | Yarn Count: | 20S2*20S2 |

| Pattern: | Woven | Weight : | 280gsm |

| Color: |

Black | Width: | 150cm |

Material: |

Pre-oxidized pan fiber, Kevlar fiber |

| Pattern: | Woven |

| Yarn Count: | 20S2*20S2 |

| Color: | Black |

| Width: |

150CM |

| Weight: | 280GSM |

Company Information

Shanghai Tanchain New Material Technology Co., Ltd is a high-tech enterprise focused on developing, producing, and marketing technical textiles products and composite materials, for the industrial, transportation, automotive, and protective industries. We have more than 8 years' experience in producing innovative products for extremely protective and labor protective applications,and with our great advantage in sourcing and technology, Tanchain has grown to be one of the leading suppliers in Chinese technical textiles market. We have a complete industrial chain and a strict quality management system.

Tanchain carefully selected raw material suppliers from dozens of first-class raw material suppliers domestically and overseas, and has signed long-term supply agreements, which ensures that we have large quantities of the best quality raw materials on a timely basis, and it is also a fundamental guarantee of the quality of our company's products.

We have built high-standard modern factories domestically and overseas, and have hired managers and technicians with first-class work experience in domestic and foreign companies, so as to ensure that our products have our own technical advantages and market competitiveness.

Good products allow us to obtain a large number of customers in domestic and overseas markets, and these high-quality customers are our company's valuable resources. Excellent customer groups give us information feedback while improving the function and quality of our products.

The quality control department has been established since the beginning of the company, and the chairman of the company attaches great importance to quality control. We have invested a huge amount of money to ensure the quality of products, which is the basis for our long-term foothold in the market. The factory manages and controls the whole process from raw materials into the factory, production and processing to finished products, and each process follows scientific norms in order for continuous improvement.

Our mission is to be recognized as a premier supplier to the markets we serve by providing quality yarns, fabrics and other textile products to satisfy the needs of our customers. Our mission will be accomplished through excellence in customer service, sales and manufacturing, and supported by teamwork of all associates. We will continue our tradition of honesty, fairness and integrity in the relationships with our customers, associates, community and stakeholders.