-

-

22S2 - 57% Pre-oxidized PAN Yarn - 28% Para-aramid - 15% Meta-aramid - Raw Materials Flame retardant

- Code:TC-BPY222

- Material:57% Pre-oxidized PAN Yarn - 28% Para-aramid - 15% Meta-aramid

- Weight:1kg/cone

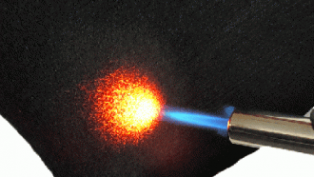

- Function:High Temperature Resistant, Flame Retardant, Fire-Proof

- Color:Army green(other heather)

- Count:22S2

SEND INQUIRY

Material: |

57% Pre-oxidized PAN Yarn - 28% Para-aramid - 15% Meta-aramid | Yarn Count: | 22S2 |

| Properties: | High temperature resistant | Weight : | 1kg/cone |

|

Spinning process: |

Ring spinning | LOI: | >38% |

Material: |

57% Pre-oxidized PAN Yarn - 28% Para-aramid - 15% Meta-aramid |

| Properties: | High temperature resistant |

|

Spinning process: |

Ring spinning |

| Yarn Count: | 22S2 |

| Weight : | 1kg/cone |

| LOI: | 38% |

Product Description

The yarn blended with pre-oxidized fiber, para-aramid and meta-aramid is a high-performance fiber blend material with many excellent properties. The following is a detailed introduction:

Raw material characteristics

- Pre-oxidized fiber: It is obtained by pre-oxidizing polyacrylonitrile fiber in air at 200-300℃ and is black. It has good flame retardancy, limiting oxygen index 40-60, and decomposition temperature ≥640℃.

- Para-aramid: Poly(p-phenylene terephthalamide), with ultra-high strength and high modulus, with a strength greater than 25 g/denier, which is 5-6 times that of high-quality steel. It has outstanding heat resistance and does not decompose or melt at a high temperature of 560℃.

- Meta-aramid: Poly(m-phenylene isophthalamide), has long-term thermal stability, can be used for a long time at a high temperature of 200℃ without aging, and the limiting oxygen index value is greater than 28%. It will not spontaneously combust or melt in the air, nor will it produce molten droplets, and it will extinguish itself after leaving the flame.

Advantages of blending

- Improve strength: The high strength and high modulus characteristics of para-aramid can improve the overall strength of the yarn, making it more durable and stretch-resistant.

- Enhance flame retardancy: Both pre-oxidized fibers and meta-aramid have good flame retardancy. After blending, the yarn has good flame retardancy and can be used in occasions where fire protection is required.

- Improve wear resistance: para-aramid and pre-oxidized fibers can enhance the wear resistance of the yarn, making it more resistant to friction and scratching, and suitable for products that require wear resistance.

- Rich color selection: Compared with pure pre-oxidized yarn, blending can enrich the color of the yarn by selecting different colors of para-aramid and meta-aramid.

Application areas

- Protective clothing: used to make fire suits, fireproof clothing, bulletproof vests, etc., providing flame retardant, bulletproof and cut-resistant protection.

- Aerospace: can be used to manufacture parts of aircraft and spacecraft, such as fuselages, wings and other structural materials, reducing weight while ensuring strength and heat resistance.

- Automobile industry: used in automobile tire cords to improve tire strength, wear resistance and heat resistance. It can also be used in automobile interior materials to increase flame retardancy.

- Electronics and electrical: can be used to make special printed circuit boards, radar antenna shields, etc., because it has good strength, modulus and electromagnetic wave transmittance.

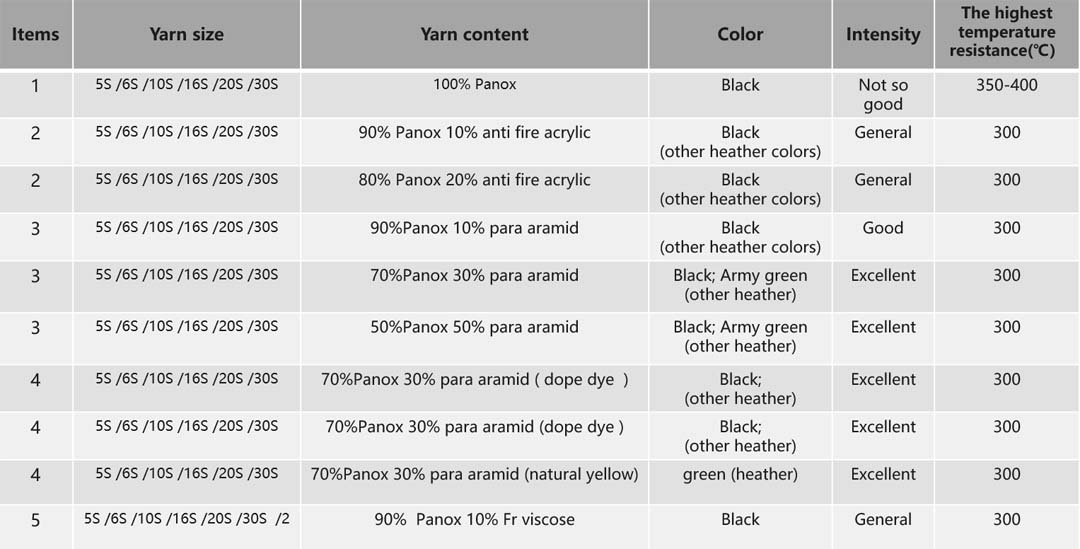

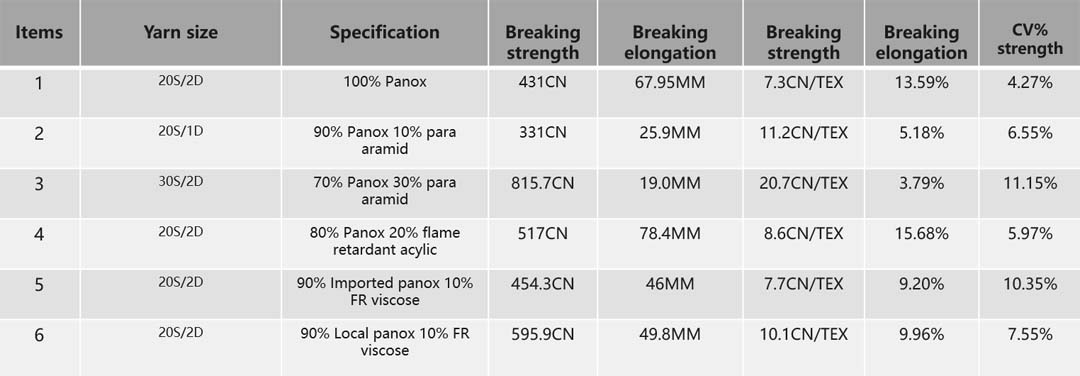

Similar Series Technical Data

Similar Yarn List