-

-

32S2 - 80% Oxidized PAN 20% Modal Blended Yarn - Flame Retardant - Anti-Fire - OX Yarn

- Code:TC-BPY322

- Material:80% Oxidized Pan Fiber 20% Modal

- Weight:1kg/cone

- Function:High Temperature Resistant, Heat Insulation, Flame Retardant, Fire Retardant

- Color:Black

- Weave:spun

- Count:32S/2

SEND INQUIRY

Material: |

80% Oxidized Pan Fiber 20% Modal | Yarn Count: | 32S2 |

| Retardant type: | Raw Fiber Flame Retardant | Weight : | 1kg/cone |

|

Spinning process: |

Ring spinning | LOI: | >42% |

Material: |

80% Oxidized Pan Fiber 20% Modal |

| Retardant type: | Raw Fiber Flame Retardant |

|

Spinning process: |

Ring spinning |

| Yarn Count: | 32S2 |

| Weight : | 1kg/cone |

| LOI: | >42% |

Product Description

The 32-count two-ply yarn blended with 80% polyacrylonitrile pre-oxidized fiber and 20% modal fiber has the following characteristics:

Raw material characteristics

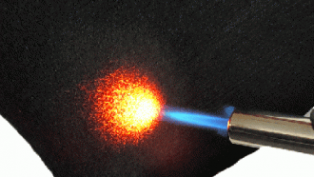

- Polyacrylonitrile pre-oxidized fiber: obtained by high-temperature heat stabilization treatment of polyacrylonitrile fiber, it has high flame retardancy, limiting oxygen index greater than 45%, the fiber does not melt, soften and shrink, and has no droplets when burning, has good heat insulation effect, acid and alkali corrosion resistance, chemical environment resistance, and radiation resistance, but also has defects such as low strength, less curling, brittle fiber, and poor cohesion between fibers.

- Modal fiber: It is a new type of viscose cellulose fiber. The raw material comes from natural wood. It has the advantages of softness, strong hygroscopicity, high strength, good wear resistance, good washability, good dyeing performance, good dimensional stability, and green environmental protection.

Yarn performance

- Fineness and count: 32 count indicates the thickness of the yarn. The higher the count, the finer the yarn. Two strands refer to two single yarns that are plied together, making the yarn stronger and more durable, and also increasing the thickness and strength of the yarn to a certain extent.

- Strength and toughness: Polyacrylonitrile-based pre-oxidized fibers improve the overall strength and toughness of the yarn to a certain extent, making it more durable and able to withstand certain tension and friction. The addition of modal fibers improves the softness and comfort of the yarn while ensuring strength.

- Flame retardant and comfort: A high proportion of polyacrylonitrile-based pre-oxidized fibers gives the yarn good flame retardant properties, making it suitable for occasions with high fire protection requirements. The addition of modal fibers gives the yarn good moisture absorption and breathability, making it more comfortable to wear and not causing a stuffy feeling on the skin.

Application areas

- Protective clothing: It can be used to make firefighting clothing, thermal insulation protective clothing, etc., which can effectively prevent the harm of flames and heat to the human body, and ensure the comfort of the wearer and improve work efficiency.

- Home furnishings: In the field of home textiles, it can be used to make bedding, curtains, etc., which can provide a comfortable use experience while increasing the safety of the product and reducing the risk of fire.

- Industrial fabrics: suitable for industrial applications that require fire resistance, wear resistance, and corrosion resistance, such as high-temperature furnace insulation materials, welding protective fabrics, etc.

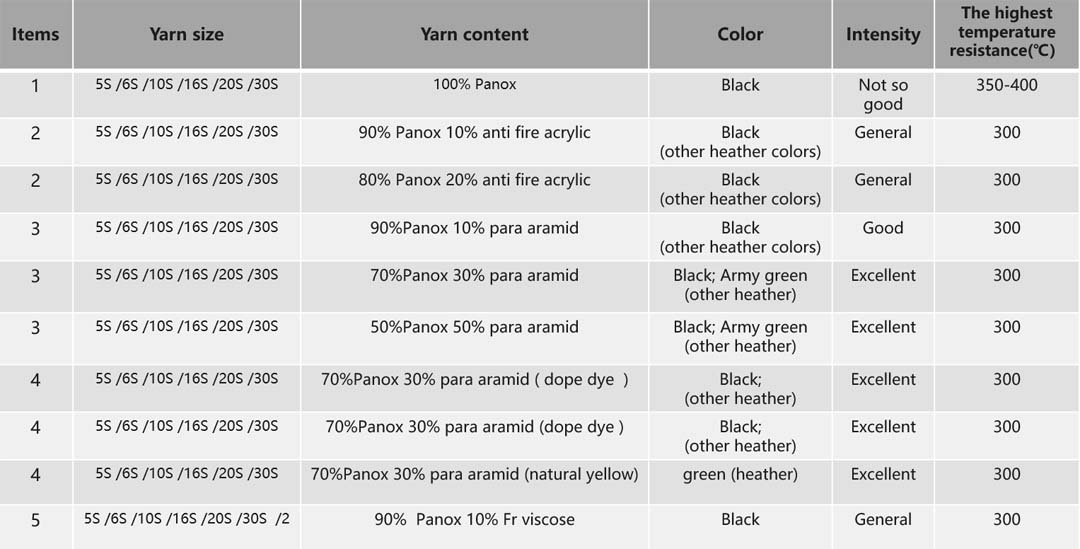

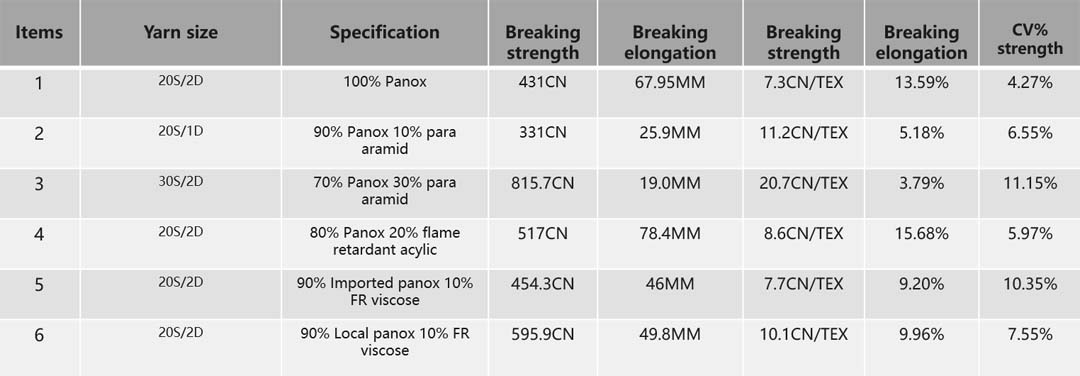

Similar Series Technical Data

Similar Yarn List