-

-

12S2 - 100% Pre-oxidized PAN Yarn - Flame retardant

- Code:TC-PY122

- Material:100% Pre-oxidized pan fiber

- Weight:1kg/cone

- Function:High Temperature Resistant, Flame Retardant, Fire-Proof

- Color:Black

- Count:12S/2

SEND INQUIRY

Material: |

100% panox yarn | Yarn Count: | 12S2 |

| Properties: | High temperature resistant | Weight : | 1kg/cone |

|

Spinning process: |

Ring Spinning | CV Strength: | 4.27% |

| Breaking Strength: | >4CN/TEX | Breaking Elongation%: | 13.59% |

Material: |

100% panox yarn |

| Properties: | High temperature resistant |

|

Spinning process: |

Ring spinning |

| Breaking Strength: | >4CN/TEX |

| Yarn Count: | 12S2 |

| Weight : | 1kg/cone |

| CV Strength: | 4.27% |

| Breaking Elongation%: | 13.59% |

Product Description

Compared with other types of flame-retardant fiber yarns, the advantages of 12S2 polyacrylonitrile-based pre-oxidized fiber yarns are as follows:

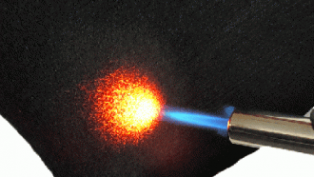

- Excellent flame retardant performance:

The limiting oxygen index is as high as 45%, with permanent flame retardancy, no burning, no melting, no molten droplets when encountering fire, and very little toxic gas is generated during combustion, which can effectively block the spread of flames and heat, and the protective performance is more reliable.

- Outstanding thermal stability:

It can maintain stable performance for a long time in a high temperature environment of 200℃-300℃, with low thermal shrinkage, stable shape and size, and is suitable for aerospace, automotive engines and other fields with high requirements for thermal stability.

- High strength and modulus:

It has high mechanical properties, high strength, large modulus, can withstand large external forces, is not easy to break and deform, and can be used to manufacture protective equipment and industrial parts with high strength requirements.

- Good chemical stability: It has good tolerance to most chemical substances, acid and alkali resistance, and corrosion resistance. It can be used in a variety of chemical environments and can adapt to work scenes and industrial production processes with chemical corrosion risks.

- Excellent thermal insulation performance:

low thermal conductivity, good thermal insulation effect, can effectively block heat transfer, can be used to manufacture thermal insulation materials, improve energy efficiency, and reduce energy consumption.

- Strong spinnability:

can be used for spinning, weaving, needle punching, stitching and other textile processing, the production process is relatively mature, can be made into different specifications and forms of yarn and products according to different needs, to meet the diverse application needs.

- Relatively high cost performance:

while ensuring good performance, the production cost is lower than some high-performance flame-retardant fiber yarns such as aramid, which can effectively control costs in large-scale applications and has more economic advantages.

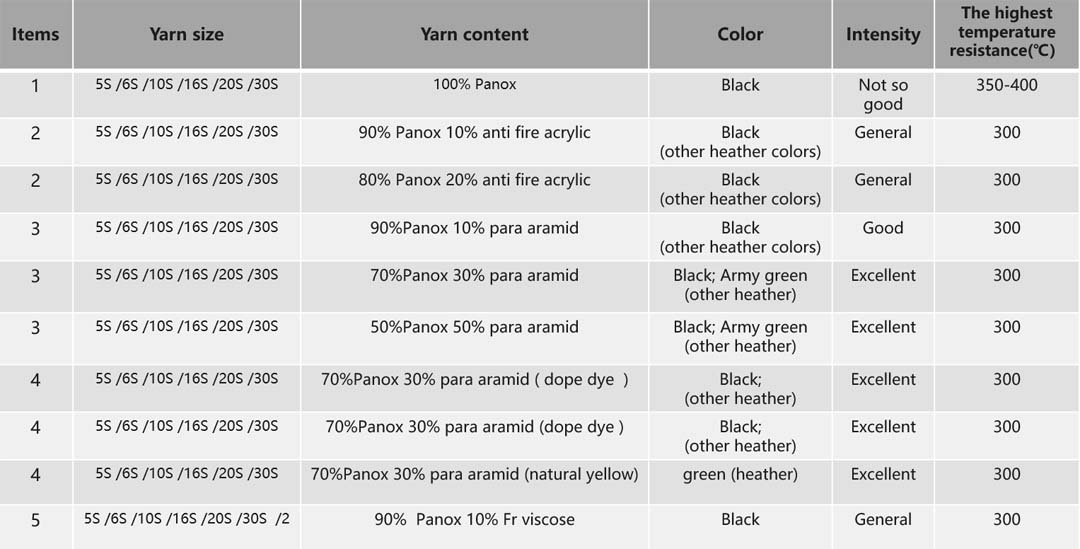

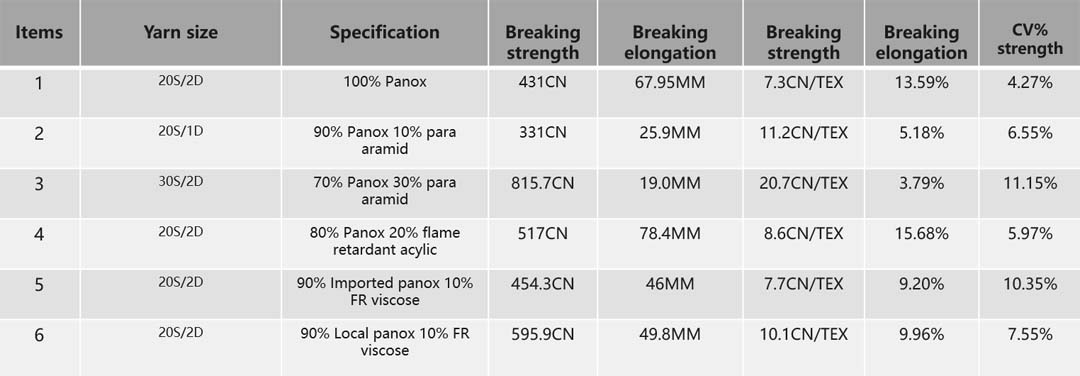

Similar Series Technical Data

Similar Yarn List