-

-

30S1 - 10% Oxidized fiber 90% FR Viscose Blended Yarn

- Code:TC-BPY301

- Material:10% Oxidized fiber 90% FR Viscose

- Weight:1kg/cone

- Function:High Temperature Resistant, Heat Insulation, Flame Retardant, Fire Retardant

- Color:Black

- Count:30S1

SEND INQUIRY

Product Properties

10% pre-oxidized fiber 90% flame retardant viscose blended yarn has the following characteristics:

- Advantages:

- Good flame retardant performance:

- Flame retardant viscose itself has a certain flame retardant property. It does not melt and drip when burning, has a self-extinguishing effect, and only produces a small amount of smoke. Pre-oxidized fiber can maintain stable performance in high temperature environment, and will not burn or melt when exposed to heat or fire. The combination of the two further improves the flame retardant performance of the blended yarn, which can effectively prevent the spread of flames and is suitable for scenes with high fire protection requirements.

- Higher strength and durability: Pre-oxidized fiber has higher strength and modulus, which makes it less likely to break and deform when subjected to external forces, providing better strength support for blended yarn. After blending with flame retardant viscose, it makes up for the relatively low strength of viscose fiber to a certain extent, improves the overall strength and durability of the yarn, and can withstand certain mechanical wear and stretching.

- Good moisture absorption and breathability: Viscose fiber is a regenerated cellulose fiber with good moisture absorption and breathability, and a high moisture regain, which can keep the human body dry and comfortable when wearing or using fabrics made of this yarn. This feature makes blended yarns advantageous in making clothing, household items, etc., especially suitable for use in hot seasons or humid environments.

- Good spinnability and processability: This blended yarn combines the advantages of pre-oxidized fiber and flame-retardant viscose, has good spinnability, can be processed through a variety of textile processes, such as spinning, weaving, needle punching, stitching, etc., and can be used to manufacture a variety of textiles. In addition, during the processing, the yarn has good stability and is not prone to problems such as breakage and hairiness, which is conducive to improving production efficiency and product quality.

- Disadvantages:

- High cost: The production process of pre-oxidized fiber is relatively complicated and the cost is relatively high. After blending with flame-retardant viscose, although the cost is reduced to a certain extent, the overall cost is still high, which may limit its application in some cost-sensitive fields.

- Dyeability may be limited: The chemical structure and properties of pre-oxidized fibers are different from those of ordinary fibers, which may have a certain impact on the dyeability of blended yarns. During the dyeing process, it is necessary to select appropriate dyes and dyeing processes to ensure that the yarn can achieve good dyeing effects.

This blended yarn has a wide range of uses, including:

- Protective equipment: It can be used to make protective equipment such as fireproof clothing, heat-insulating clothing, and fire-fighting clothing. These protective equipment need to have good flame retardant and heat-insulating properties to protect the safety of users. The excellent flame retardant properties and certain heat-insulating capacity of this blended yarn make it very suitable for the manufacture of such protective equipment.

- Household items: It can be used to produce household items such as curtains, sofa covers, and carpets. These household items may come into contact with fire sources in daily life, such as candles, lighters, etc. The use of yarns with flame retardant properties can reduce the risk of fire. At the same time, its good moisture absorption and breathability can also bring a comfortable experience to the home environment.

- Industrial textiles: In industrial fields, such as petrochemicals, power and other industries, workers need to wear work clothes with flame retardant properties. This blended yarn can be used to make industrial work clothes to protect the safety of workers in dangerous environments. In addition, it can also be used to make high-temperature furnace insulation materials, interior materials for vehicles, etc.

- Aerospace field: The aerospace field has very high performance requirements for materials, requiring materials to have good flame retardant properties, high strength and lightweight characteristics. After further processing and treatment, this blended yarn may be used in the aerospace field, such as aircraft interior materials, parachutes, etc.

From the perspective of use prospects, 10% pre-oxidized fiber 90% flame retardant viscose blended yarn has broad development prospects:

- Market demand growth: As people's awareness of safety continues to improve, the demand for flame retardant textiles is also gradually increasing. Whether in public places, homes or industrial fields, the demand for textiles with good flame retardant properties is constantly expanding. As a high-performance flame retardant material, this blended yarn can meet the market demand for flame retardant textiles and has great market potential.

- Continuous technological progress: With the continuous advancement of textile technology, the performance improvement and optimization of pre-oxidized fibers and flame retardant viscose will continue. This will further improve the performance of blended yarns, reduce costs, and expand their application range. For example, by improving the production process, improving the production efficiency and quality of pre-oxidized fibers and reducing their costs; developing new flame retardants and treatment methods to improve the flame retardant properties and durability of flame-retardant viscose.

- Increased environmental awareness: Against the backdrop of increasing environmental awareness, people's demand for green and environmentally friendly textiles is also increasing. Flame-retardant viscose fibers are regenerated cellulose fibers that can be naturally degraded after being discarded, meeting environmental protection requirements. Pre-oxidized fibers can also reduce the impact on the environment by optimizing the process during production. The environmentally friendly characteristics of this blended yarn will give it a greater advantage in future market competition.

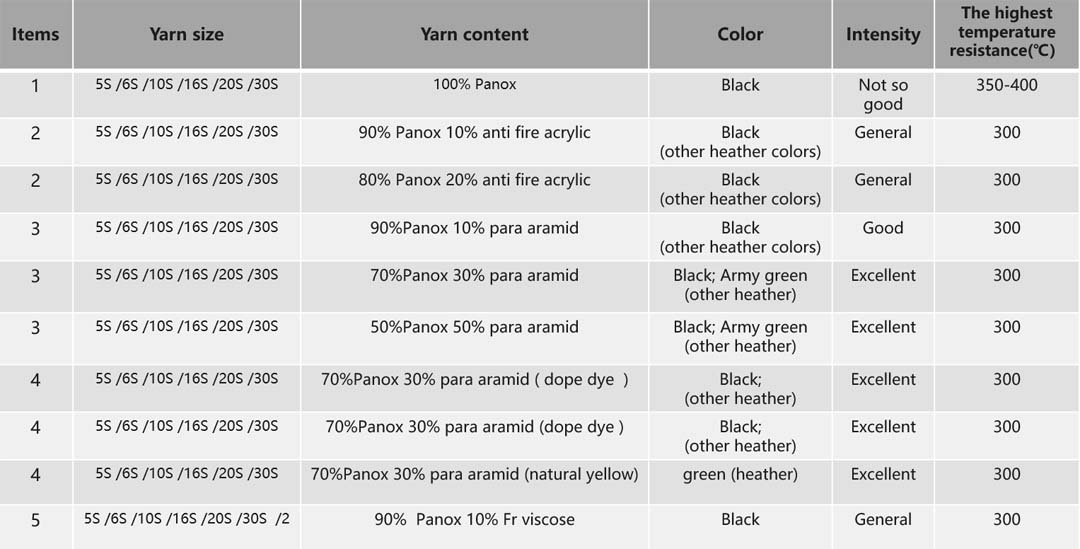

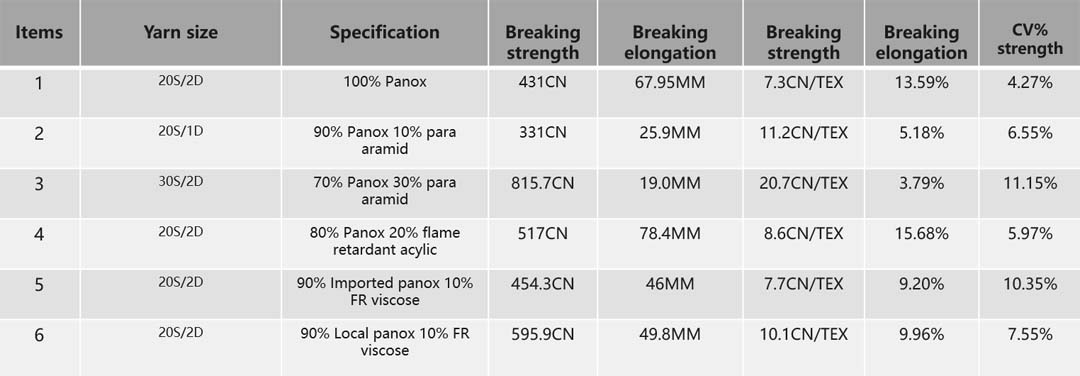

Similar Series Technical Data

Similar Yarn List