-

-

8S2 - 100% Pre-oxidized PAN Yarn - Raw Materials Flame retardant

- Code:TC-PY082

- Material:100% Pre-oxidized pan fiber

- Weight:1kg/cone

- Function:High Temperature Resistant, Flame Retardant, Fire-Proof

- Color:Black

- Count:8S/2

SEND INQUIRY

Material: |

100% panox yarn | Yarn Count: | 8S2 |

| Properties: | High temperature resistant | Weight : | 1kg/cone |

|

Spinning process: |

Ring spinning | CV Strength: | 4.27% |

| Breaking Strength: | >4CN/TEX | Breaking Elongation%: | 13.59% |

Material: |

100% panox yarn |

| Properties: | High temperature resistant |

|

Spinning process: |

Ring spinning |

| Breaking Strength: | >4CN/TEX |

| Yarn Count: | 8S2 |

| Weight : | 1kg/cone |

| CV Strength: | 4.27% |

| Breaking Elongation%: | 13.59% |

Product Description

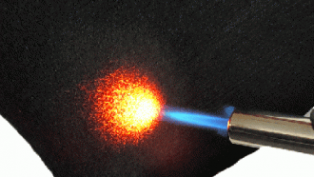

The flame retardant yarn is a kind of yarn with flame retardant properties.

Its flame retardancy is determined by the characteristics of the fiber material itself, not by adding flame retardants through external methods such as post-finishing. In the process of producing this kind of yarn, fiber raw materials with flame retardant function are selected. When these fibers encounter flames, they can prevent or delay the burning process through their own chemical structure or physical properties. For example, some high-performance flame retardant fibers can form a char layer when burning. This char layer can isolate oxygen and heat, thereby achieving a flame retardant effect.

"8 counts 2 strands" is a description of yarn specifications.

The "count" in "8 counts" is the unit of yarn fineness, called English count. English count is a fixed weight unit. It refers to the length of 8 840 yards (about 768.096 meters) of 1 pound (about 0.4536 kg) of yarn at the standard regain, which is 8 English counts. The smaller the count, the thicker the yarn.

"2 strands" means that the yarn is twisted together by two single yarns. This two-ply structure makes the yarn stronger and more abrasion-resistant than single yarn, and the look and feel will also be different, being fuller and thicker.

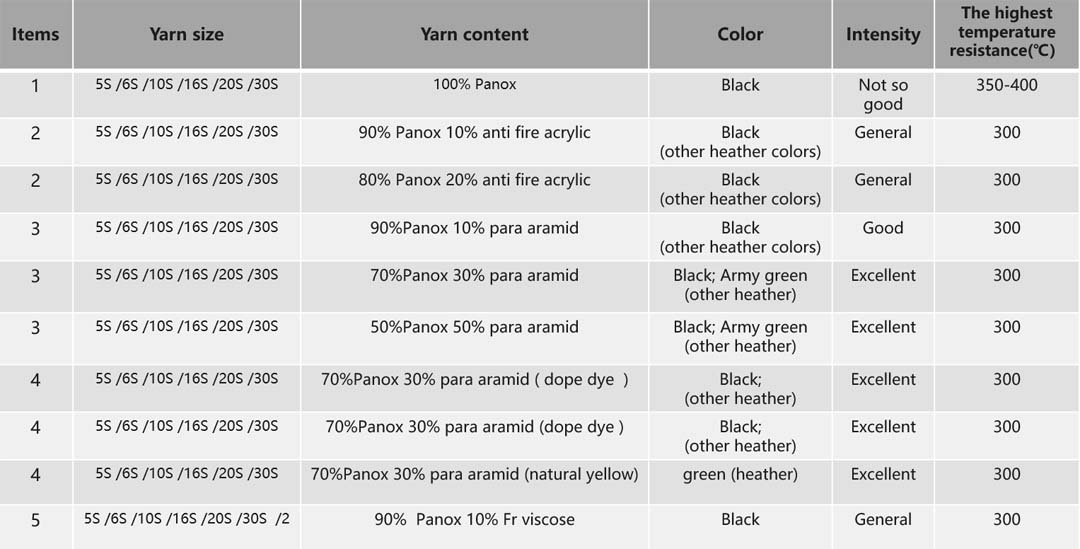

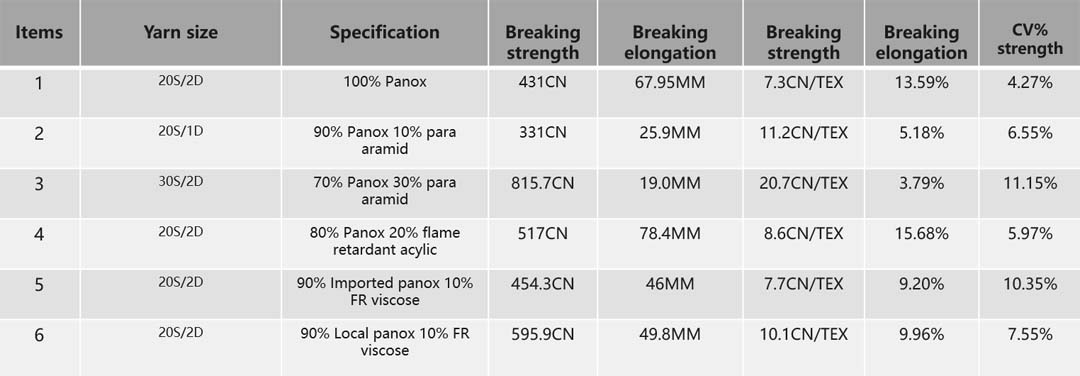

Similar Series Technical Data

Similar Yarn List