-

-

20S2 - 70% Pre-oxidized PAN Yarn - 30% Para-aramid - Raw Materials Flame retardant

- Code:TC-BPY202

- Material:70% Pre-oxidized PAN Yarn - 30% Para-aramid

- Weight:1kg/cone

- Function:High Temperature Resistant, Flame Retardant, Fire-Proof

- Color:Army Green(Other heather colors)

- Count:20S2

SEND INQUIRY

Material: |

70% Pre-oxidized PAN Yarn - 30% Para-aramid | Yarn Count: | 20S2 |

| Properties: | High temperature resistant | Weight : | 1kg/cone |

|

Spinning process: |

Ring spinning | LOI: | >38% |

Material: |

70% Pre-oxidized PAN Yarn - 30% Para-aramid |

| Properties: | High temperature resistant |

|

Spinning process: |

Ring spinning |

| Yarn Count: | 20S2 |

| Weight : | 1kg/cone |

| LOI: | 38% |

Product Description

The yarn blended with 70% pre-oxidized fiber and 30% para-aramid fiber has the following characteristics:

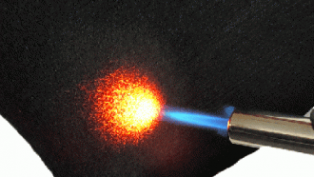

Good high temperature resistance

The pre-oxidized fiber itself has excellent thermal stability, and its limiting oxygen index is greater than 45%. During combustion, the fiber does not melt, soften, shrink, or have droplets. It is a non-combustible product with a decomposition temperature of ≥640°C; para-aramid fiber also has good high temperature resistance, and does not decompose or melt at 560°C. After the two are blended, the high temperature resistance of the yarn is further enhanced.

Strong flame retardant performance

Both pre-oxidized fiber and para-aramid fiber are flame retardant fibers. The limiting oxygen index of the blended yarn is improved, and the flame retardant effect is better than that of para-aramid yarn. It can effectively prevent the spread of flames and reduce the risk of combustion.

High strength

The strength of para-aramid fiber is high, which is 5-6 times that of steel wire, 3 times that of glass fiber, and 2 times that of high-strength nylon industrial yarn. The modulus is 2-3 times that of steel wire or glass fiber, 10 times that of high-strength nylon industrial yarn, and the toughness is 2 times that of steel wire. After blending with pre-oxidized fiber, the overall strength of the yarn can be improved, making it more durable.

Good chemical stability

Both have good acid and alkali corrosion resistance, chemical environment resistance, and radiation resistance. After blending, the yarn can maintain stable performance in a variety of complex chemical environments.

Improved spinnability and wearability

Pre-oxidized fiber has low strength and curling The problems of poor spinnability such as less bend, brittle fiber, and poor cohesion between fibers are improved after blending with para-aramid fiber. The yarn has uniform yarn dryness and stable performance. At the same time, the yarn color is enriched, and the wear resistance and wearing characteristics of the yarn are improved.

The main application areas of this blended yarn are as follows:

Protective clothing

It can be used to make fire suits, fireproof clothing, flash explosion masks and gloves, etc., to provide reliable protection for firefighters, soldiers and personnel working in high temperature, flammable, explosive and other dangerous environments, protecting them from flames, high temperatures, explosions and shocks.

Industrial insulation

It is suitable for thermal insulation materials in the industrial field, such as thermal insulation gloves Covers, insulation pads, etc. can effectively isolate high temperatures, prevent heat transfer, and protect the safety of operators. They can also be used for some equipment and places that require heat insulation.

Aerospace

It can be used to manufacture some high-temperature resistant and flame-retardant parts and materials in the aerospace field, such as aircraft interior materials and insulation materials, which help improve the safety and reliability of aircraft.

Automobile manufacturing

It can be used for flame-retardant materials for automotive interiors, such as fabrics for seats, dashboards, etc., to improve the fire resistance of the car and ensure the safety of passengers. In addition, it can also be used to manufacture insulation materials for parts such as the engine compartment of the car to reduce the impact of heat on surrounding parts.

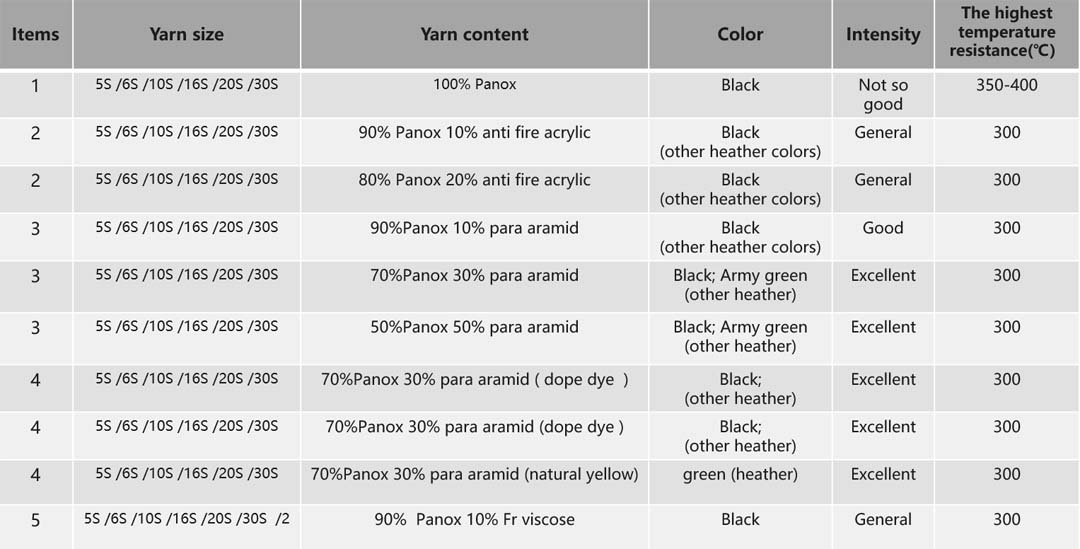

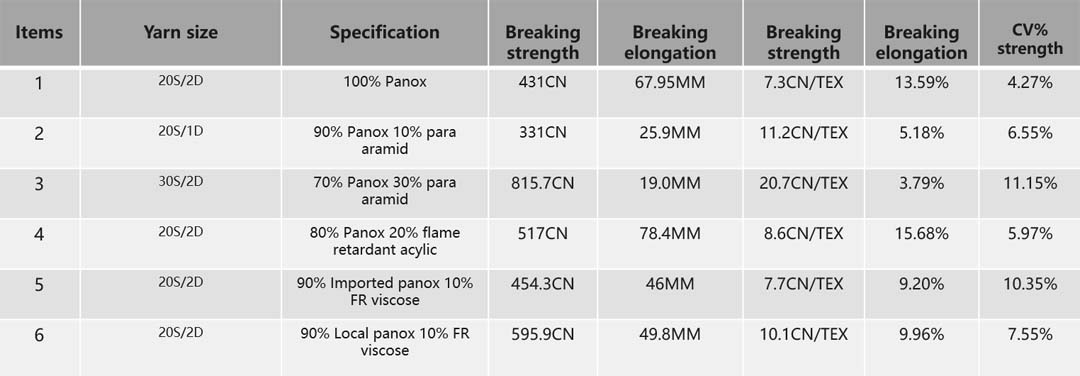

Similar Series Technical Data

Similar Yarn List