-

Aramid fiber used in Fire fighting suit

-

Aramid fibers can be found in most firefighter gear. Together, these innovative fibers help provide proven protection, durability, and comfort from the inside out.

As a basic component of firefighter protective clothing, the requirements for flame retardant performance are particularly important. The emergence of meta-aramid fiber has enabled the upgrading of fire-fighting clothing. Allows firefighters to completely eliminate the cumbersome firefighting suits that only have leather, heavy wool and canvas, and achieve performance improvements from fabrics and linings.

At present, firefighter, fire-fighting suits, fire suits made of meta-aramid colored fibers have been used in various fire-fighting systems. The meta-aramid colored fibers are also equipped with armed police forest firefighter uniform.

Because of its excellent performance, meta-aramid is widely used in metallurgy, construction, shipbuilding, petroleum, chemical, forestry, fire protection, military and other fields, and has become the best choice for processing all kinds of special protective clothing.

Firefighters have a heavy load to bear — their turnout gear shouldn’t add to it. So Aramid fibers help manufacturers create fire resistant liners, outer shells, and accessories that not only stand up to the thermal hazards they may face, but also help them get the job done without getting in the way of mobility.

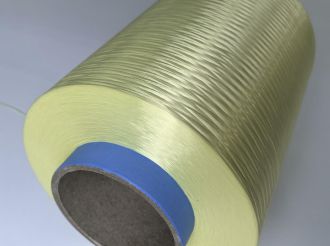

Unlike other materials and fibers available, gear and accessories made with meta aramid fiber are inherently flame-resistant and won’t melt, drip, or support combustion in the air. And the thermal protection off is permanent — its superior flame resistance cannot be washed out or worn away. Para aramid helps manufacturers enhance the overall durability and strength of lightweight turnout gear outer-shell-and-thermal-liner systems. It is five times stronger than steel on an equal weight basis, yet is lightweight, comfortable, and thermally protective.

Both of these innovative fibers are found in each layer of most turnout gear for ultimate protection:

●The Outer Shell

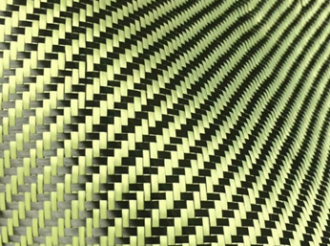

Meta aramid and Para aramid fibers are engineered together and sometimes

with other high-temperature fibers to form materials that help stand

up to heat, stay strong, and protect the inner components. Para aramid

filament is engineered into premium fabrics to help reduce fabric

profile while strengthening fabrics to new levels of performance.

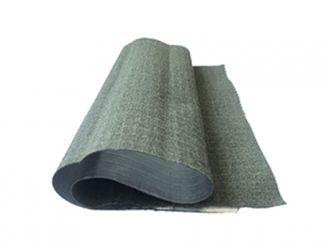

●The Moisture Barrier

Fabrics made of meta aramid fiber and non-wovens help

the most trusted and reliable moisture barrier manufacturers provide

strong flame-resistant substrates for their liquid-impermeable films.

The moisture barrier helps protect against the intrusion of water,

chemicals, and viral agents. These barriers are also breathable, which

allows metabolic heat to escape and helps reduce the overall heat stress

during strenuous activities.

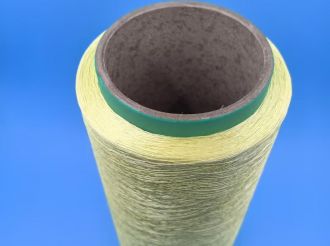

●The Thermal Liners

Meta aramid and Para aramid fiber batts and the meta aramid non-wovens are combined

with face cloths made with meta aramid and para aramid fiber to help provide

durable, flexible, heat-insulating components. Thermal liners made with

multi-layer meta aramid non-wovens are among the thinnest, most

flexible, most breathable components on the market. Face cloths using para aramid filament yarns help reduce surface friction, improving overall

garment mobility. Water-wicking or -repellent finishes on individual

layers improve moisture management and reduce garment-drying time.