-

-

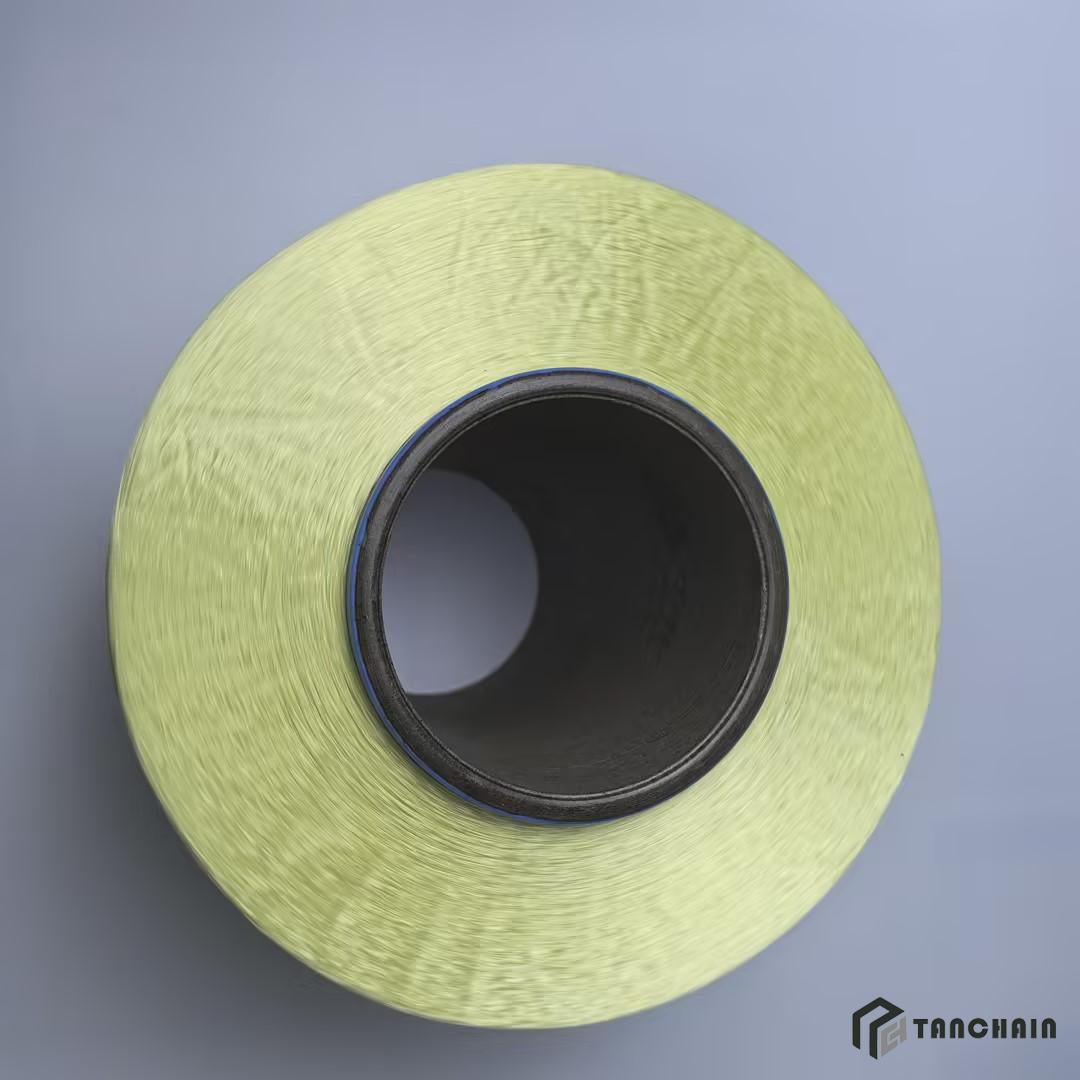

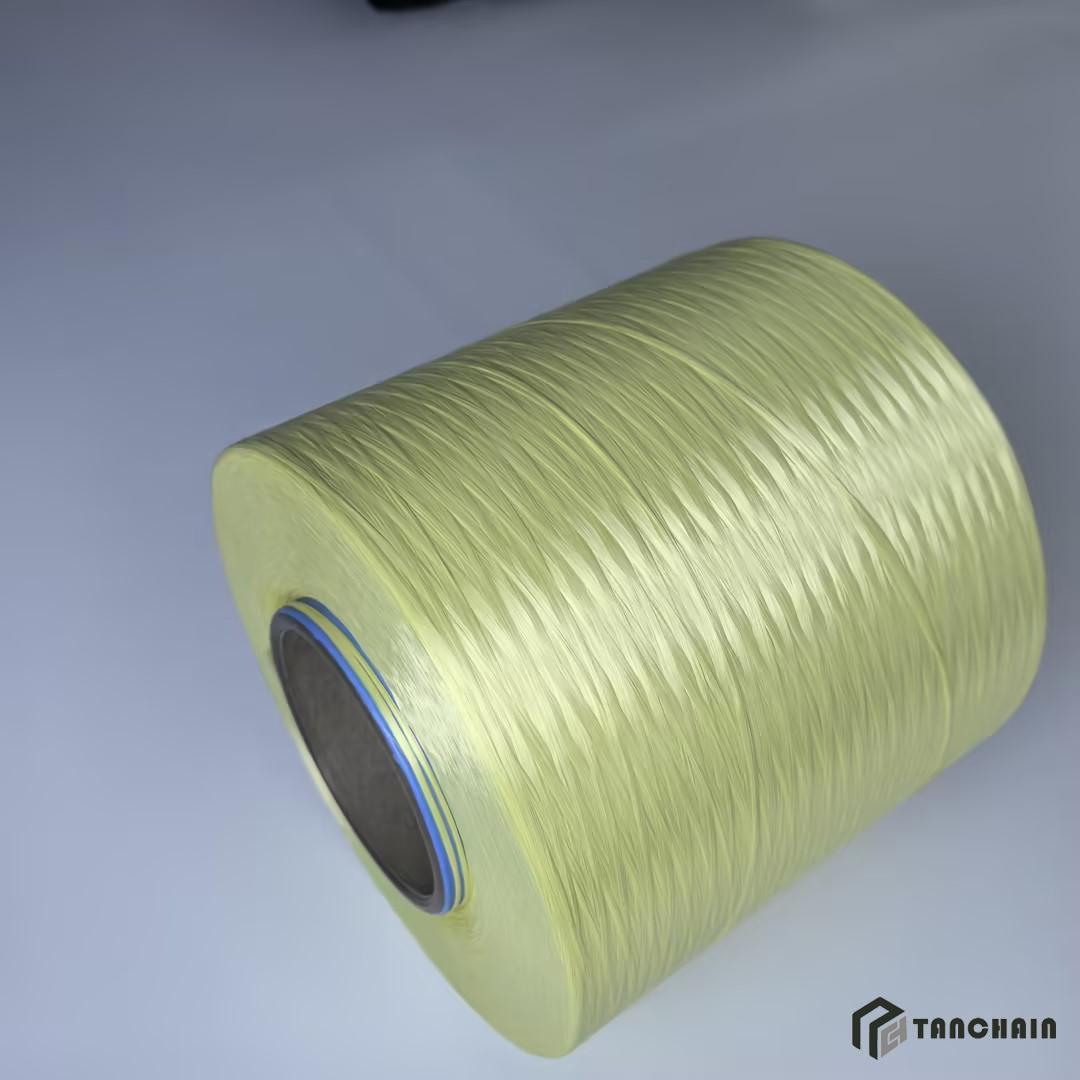

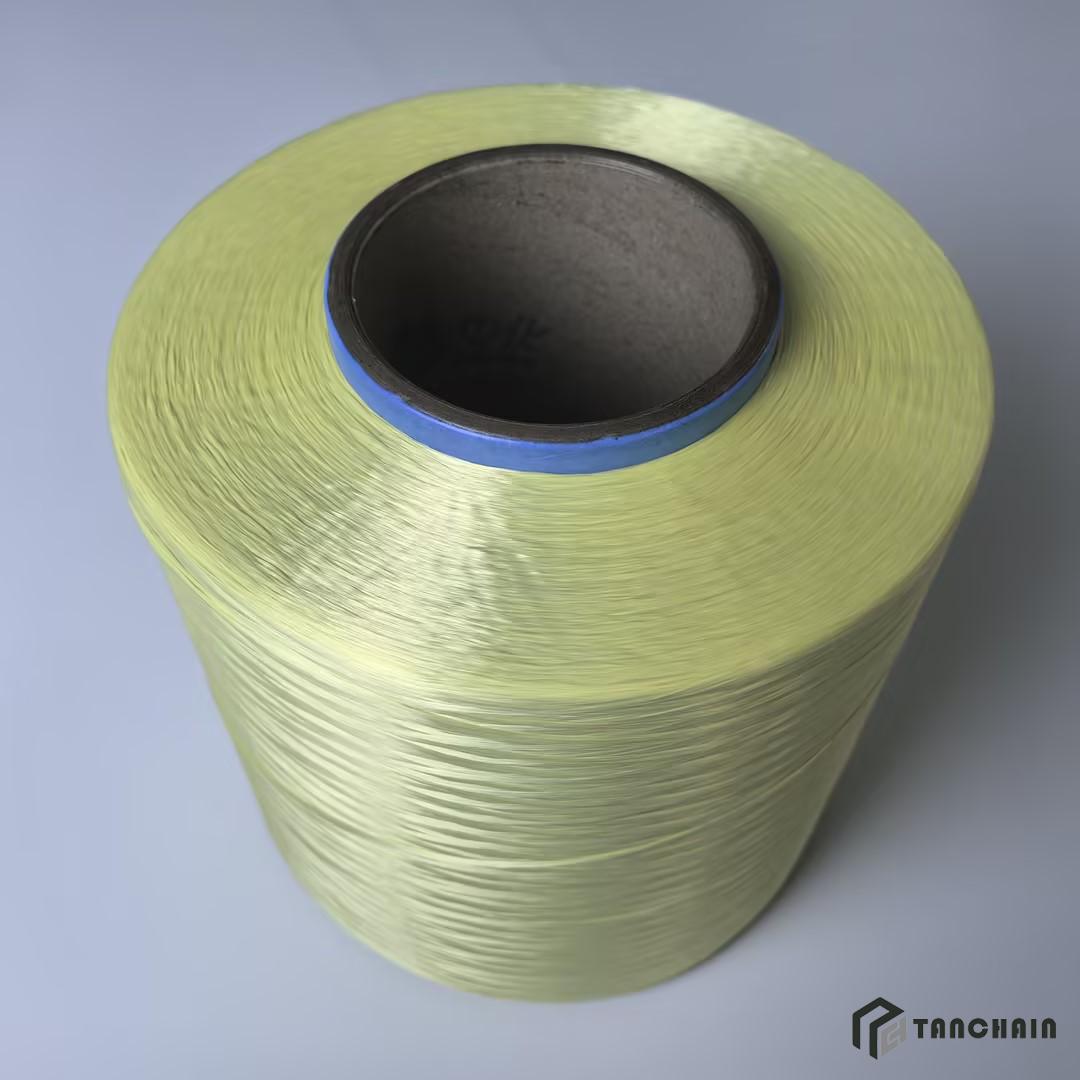

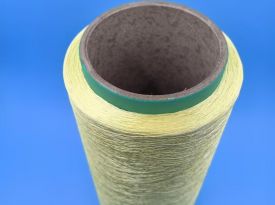

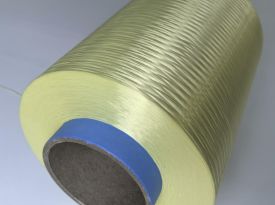

3000D - Para Aramid filaments - High Strength

- Code:TC-K3000D

- Material:100% para aramid filaments

- Weight:5kg/cone

- Function:High Temperature Resistant, Impact resistant, Abrasion Resistant

- Color:Yellow

- Count:3000D/3300dtex

SEND INQUIRY

Material: |

100% para aramid | Yarn Count: | 3000D |

| Dyeing: | Dope Dyed | Weight : | 5kg/cone |

| Yarn Type: |

Filaments | Color | Yellow |

Material: |

100% para aramid |

| Dyeing: | Dope Dyed |

| Yarn Type: | Filaments |

| Yarn Count: | 3000D |

| Weight : | 5kg/cone |

| Color: | Yellow |

Product Description

Generally speaking, 3000D para-aramid filament is indeed cheaper than 1500D para-aramid filament and has a higher cost-effectiveness for the following reasons:

Production cost

During the production process, the unit output of 3000D para-aramid filament is relatively high, and the fixed cost allocated to each unit product is relatively small. When producing 1500D para-aramid filament, more sophisticated process control and equipment adjustment are required to ensure the fineness and performance of the fiber, which increases the production cost.

Application range

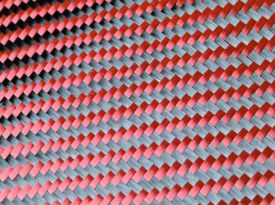

Due to its thicker fiber diameter and higher strength, 3000D para-aramid filament is suitable for fields with high strength requirements and good wear resistance requirements, such as bulletproof vests, bulletproof helmets, aerospace structural components, etc., which can reduce costs while ensuring performance. 1500D para-aramid filament is mainly used in fields with high requirements for flexibility and lightness, such as high-end protective clothing, aerospace interiors, etc. The application range is relatively narrow, and it lacks advantages in some large-scale application scenarios that are sensitive to cost.

Market supply and demand

The market supply of 3000D para-aramid filament is relatively large, there are many manufacturers, the market competition is relatively sufficient, and the price is relatively more competitive. However, the market demand for 1500D para-aramid filament is relatively small, and the output of manufacturers is relatively low, resulting in its relatively high price.

Use in the field of sporting goods

- Tennis rackets: 3000D aramid filament has high strength and high rigidity, which can make tennis rackets withstand greater force when hitting the ball without deformation, and improve the power and accuracy of hitting the ball. At the same time, its relatively light weight allows athletes to control the racket more flexibly, and enhance the reaction speed and control ability of hitting the ball.

- Golf clubs: It can be used to manufacture the shaft of golf clubs. Its high strength can withstand the huge impact force generated when hitting the ball, ensuring the stability and durability of the clubs. In addition, the low density of aramid filaments helps reduce the weight of the club, making it easier for players to swing and increase the distance of the shot.

- Bicycles: It can be used to manufacture bicycle frames, spokes and other parts. In the frame, it can reduce weight while ensuring strength, improving the acceleration and handling performance of the bicycle; when used for spokes, its high strength and fatigue resistance can ensure the reliability of the spokes under high-speed driving and complex road conditions, reducing the risk of deformation and breakage.

- Skis: Skis with 3000D aramid filaments have better impact resistance and toughness, can withstand various stresses and vibrations during skiing, and are not easy to break. At the same time, its light weight helps skiers to control the skis more easily and improve the skiing experience.

- Sailing: It can be used to manufacture sails, ropes and other parts of sailboats. As sailing material for sailboats, the high strength and light weight of aramid filaments can make the sails better maintain their shape under the action of wind and improve the sailing efficiency of sailboats; as ropes, their high tensile strength and wear resistance can ensure the reliability and service life of ropes in harsh marine environments.

Use in packing field

- Sealing performance: 3000D aramid filaments have good flexibility and elasticity. After being woven into packing, they can tightly fill the sealing cavity and effectively prevent medium leakage. Its high strength and wear resistance enable it to maintain a good sealing effect during long-term use and reduce leakage problems caused by poor sealing.

- Corrosion resistance: Aramid filaments have excellent chemical corrosion resistance and can resist the erosion of various chemical media such as acids, alkalis, and salts. It is suitable for a variety of complex chemical working conditions. Therefore, 3000D aramid packing can be widely used in sealing equipment in the petroleum, chemical, pharmaceutical and other industries.

- High temperature resistance: Aramid filaments can still maintain good mechanical properties at high temperatures, and the packing made of them can work stably within a certain temperature range. Generally speaking, aramid packing can withstand high temperatures of around 200℃-280℃, and can meet the sealing requirements of some high-temperature equipment.

- Strong adaptability: aramid packing has good adaptability and can be customized according to different sealing requirements and working conditions, such as adjusting the braiding density, adding lubricants or impregnation treatment, etc., to meet various special sealing requirements.

WORKSHOP

PARTNERS