-

-

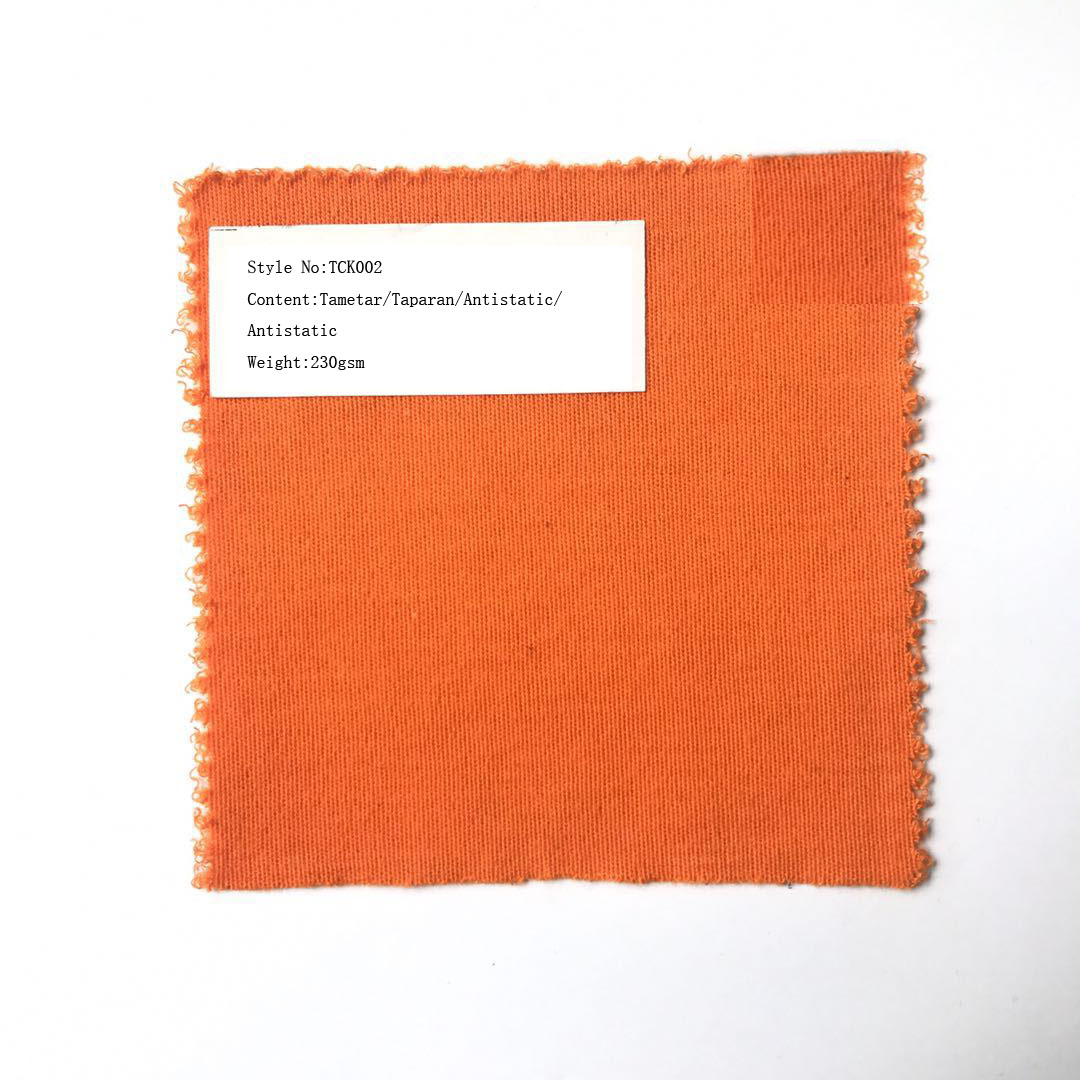

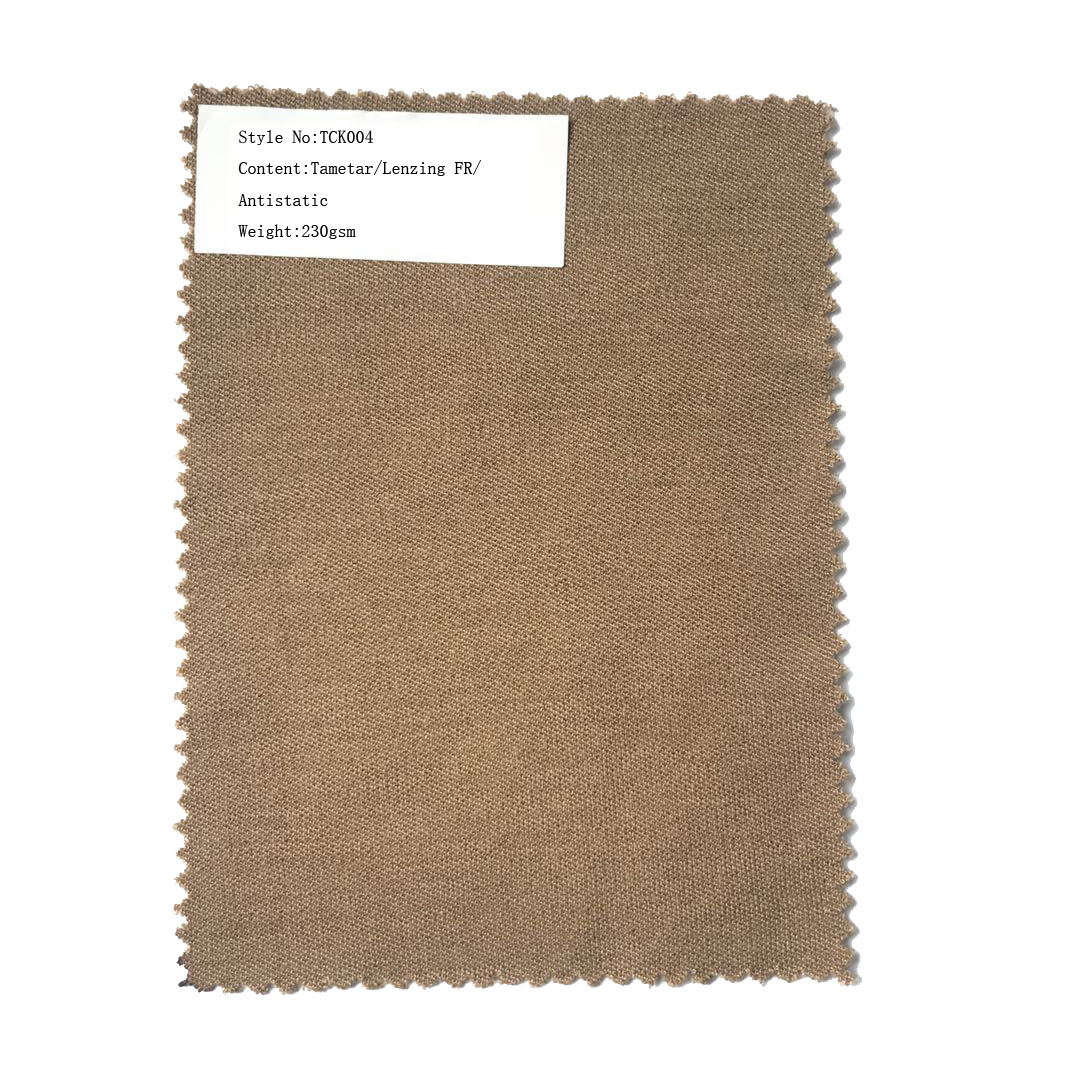

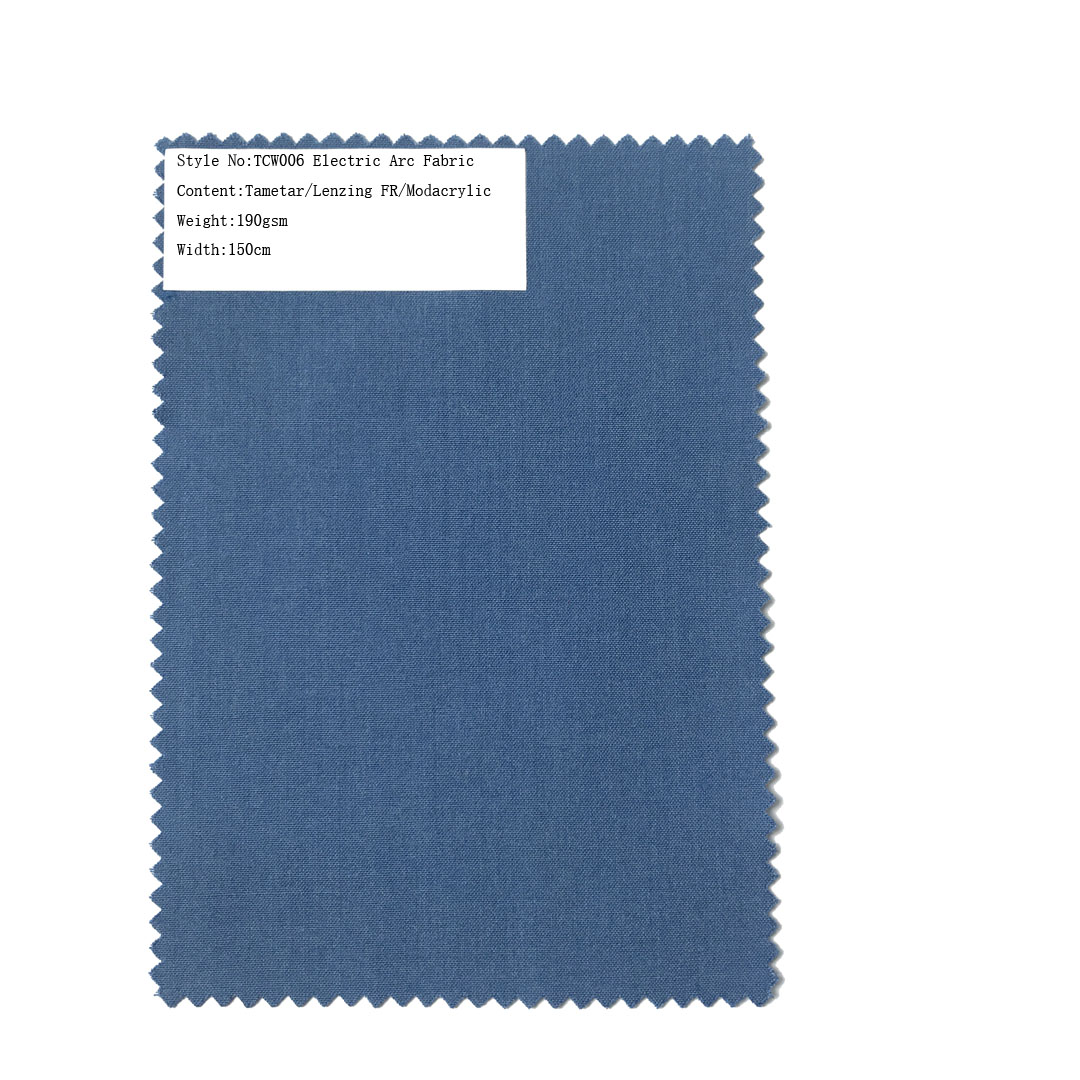

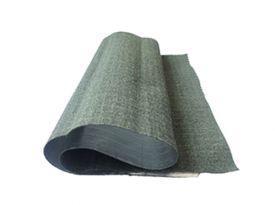

220gsm - Flame Retardant - Para Aramid Fabric - weaving - 250℃

- Code:TC-KF220

- Material:100% para aramid

- Weight:220 gsm

- Function:Firefighter uniform, petrochemical industry, flight suit, spacesuit, military police uniform

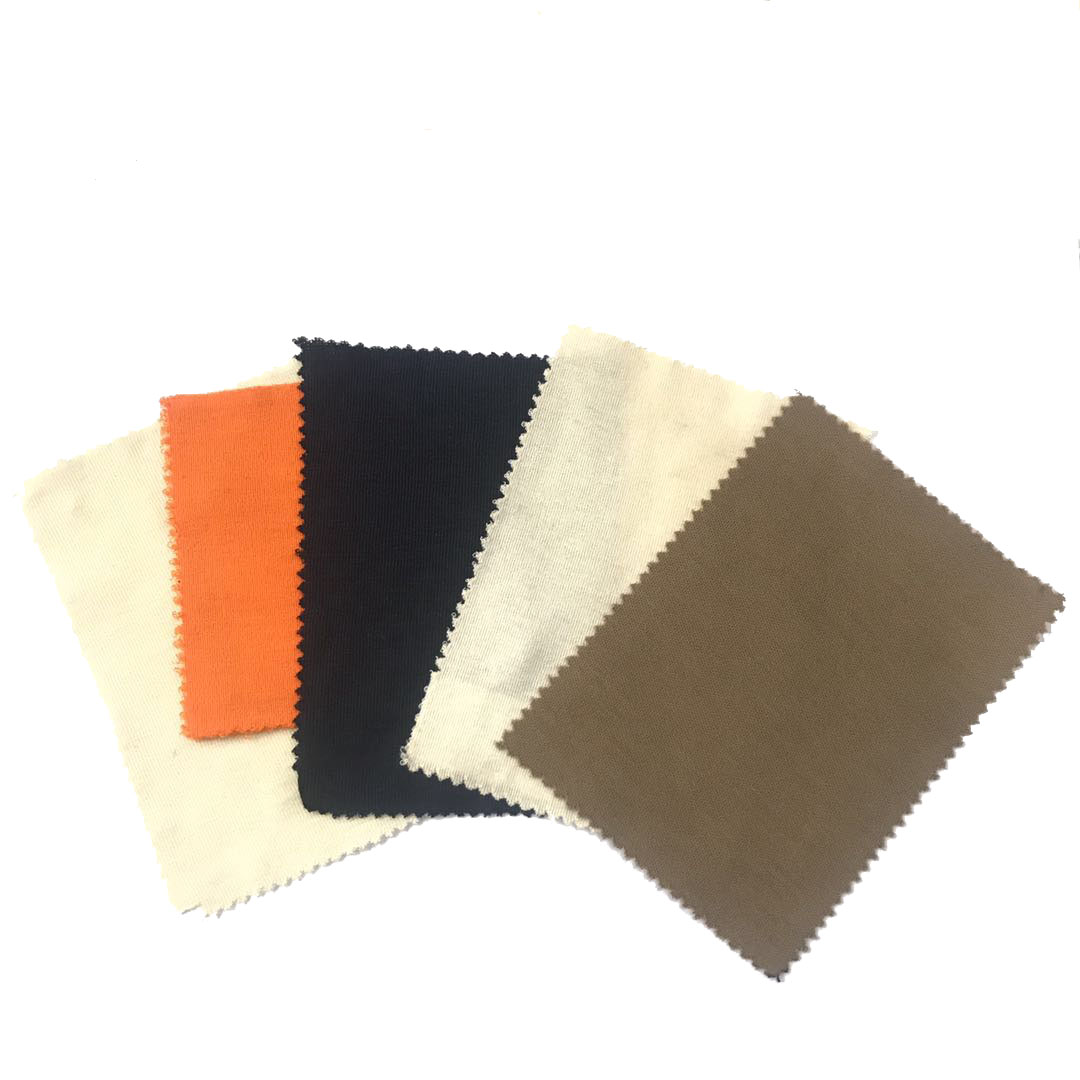

- Color:Cream, Black, Grey, Blue, Orange, Khaki

- Weave:weaving

- Width:150CM

SEND INQUIRY

Product Properties

Excellent flame retardant properties, low flammability the limiting oxygen index(LOI) is from 29% to 40%, start to carbonise and decompose above 500℃

Excellent high temperature resistance, It is able to work for a long period of time under acid base from -200℃ to 250℃, 70% strength of threads remains after being in 290℃ for 1000 hours

Chemical stability, has a high resistance to weak acid, weak base and the majority of organic solvents

Good textile properties, high resistance to breakage and its high break elongation ratio guaranteed the end product with high intensity, good product longevity, and better tolerance to injection

No Melt Drip properties, flame resistant with self-extinguish nature and non-melt drip characteristic.

High Strength and low weight, excellent strength-to-weight ratio, due to the high hydrogen bonds, the strength of Taparan®para aramid can reach up to above 28g/D. Its specific strength is 5-6 times that of steel wire , its specific modulus is 2-3 times that of steel wire or glass fiber , and its flexibility is 2 times that of steel wire while the weight is only 1/5 that of the steel wire.

High modulus

High dimensional stability: very low creep, small negative thermal expansion coefficient

Excellent thermal stability: usable across a wide temperature range, no melting point, high heat stability, low heat conductivity

High cut resistance, para-aramid fabric had higher cut, abrasion and puncture resistance properties.

Electrically non-conductive

Long, well-defined lifetime

Material: |

100% para aramid, kevlar | Yarn Count: | 20S2 |

| Pattern: | weaving | Weight : | 220gsm |

| Warp and weft density: |

Width: | 150cm | |

| Warp Breaking Strength: | 1727N | Warp Tearing Strength: | 273.7N |

| Weft Breaking Strength: | 1409N | Weft Tearing Strength: | 249.3N |

Material: |

100% para aramid, kevlar |

| Pattern: | weaving |

| Warp and weft density: | |

| Warp Breaking Strength: | 1727N |

| Weft Breaking Strength: | 1409N |

| Yarn Count: | 20S2 |

| Weight : | 210gsm |

| Width: | 150cm |

| Warp Tearing Strength: | 273.7N |

| Weft Tearing Strength: | 249.3N |

Product Description

Para-aramid fabric is suitable for use across a wide range of challenging applications and industries, from ballistic protection to heat and cut protection, and from oil and gas to the automotive and telecommunications industries, from civilian products to military products.

| Content: | 100% para aramid |

| Specification : | 100-600gsm |

| Color: | Yellow, Red, Cream, Black, Grey, Blue, Orange, Khaki etc., Customized color is available |

| Feature: | Radiation resistance, mechanical stability, electrical insulation, Low Shrinkage, High Temperature Resistant, Chemical-Resistant, Abrasion-Resistant, High Tenacity, flame retardant, self-extinguishing, high cut resistance, flame retardant |

| MOQ: | 10 kilograms |

| Meet standard : | AATCC/ASTM, EN, ISO, GB, AS |

| Application : | Used for protective clothing, gloves, firefighter uniform, flame retardant curtains, fire blanket, anti-cut gloves, bulletproof, shoes, Personal protective equipment, military protective wear. |

Company Information

Shanghai Tanchain New Material Technology Co., Ltd is a high-tech enterprise focused on developing, producing, and marketing technical textiles products and composite materials, for the industrial, transportation, automotive, and protective industries. We have more than 8 years' experience in producing innovative products for extremely protective and labor protective applications,and with our great advantage in sourcing and technology, Tanchain has grown to be one of the leading suppliers in Chinese technical textiles market. We have a complete industrial chain and a strict quality management system.

Tanchain carefully selected raw material suppliers from dozens of first-class raw material suppliers domestically and overseas, and has signed long-term supply agreements, which ensures that we have large quantities of the best quality raw materials on a timely basis, and it is also a fundamental guarantee of the quality of our company's products.

We have built high-standard modern factories domestically and overseas, and have hired managers and technicians with first-class work experience in domestic and foreign companies, so as to ensure that our products have our own technical advantages and market competitiveness.

Good products allow us to obtain a large number of customers in domestic and overseas markets, and these high-quality customers are our company's valuable resources. Excellent customer groups give us information feedback while improving the function and quality of our products.

The quality control department has been established since the beginning of the company, and the chairman of the company attaches great importance to quality control. We have invested a huge amount of money to ensure the quality of products, which is the basis for our long-term foothold in the market. The factory manages and controls the whole process from raw materials into the factory, production and processing to finished products, and each process follows scientific norms in order for continuous improvement.

Our mission is to be recognized as a premier supplier to the markets we serve by providing quality yarns, fabrics and other textile products to satisfy the needs of our customers. Our mission will be accomplished through excellence in customer service, sales and manufacturing, and supported by teamwork of all associates. We will continue our tradition of honesty, fairness and integrity in the relationships with our customers, associates, community and stakeholders.